Blog

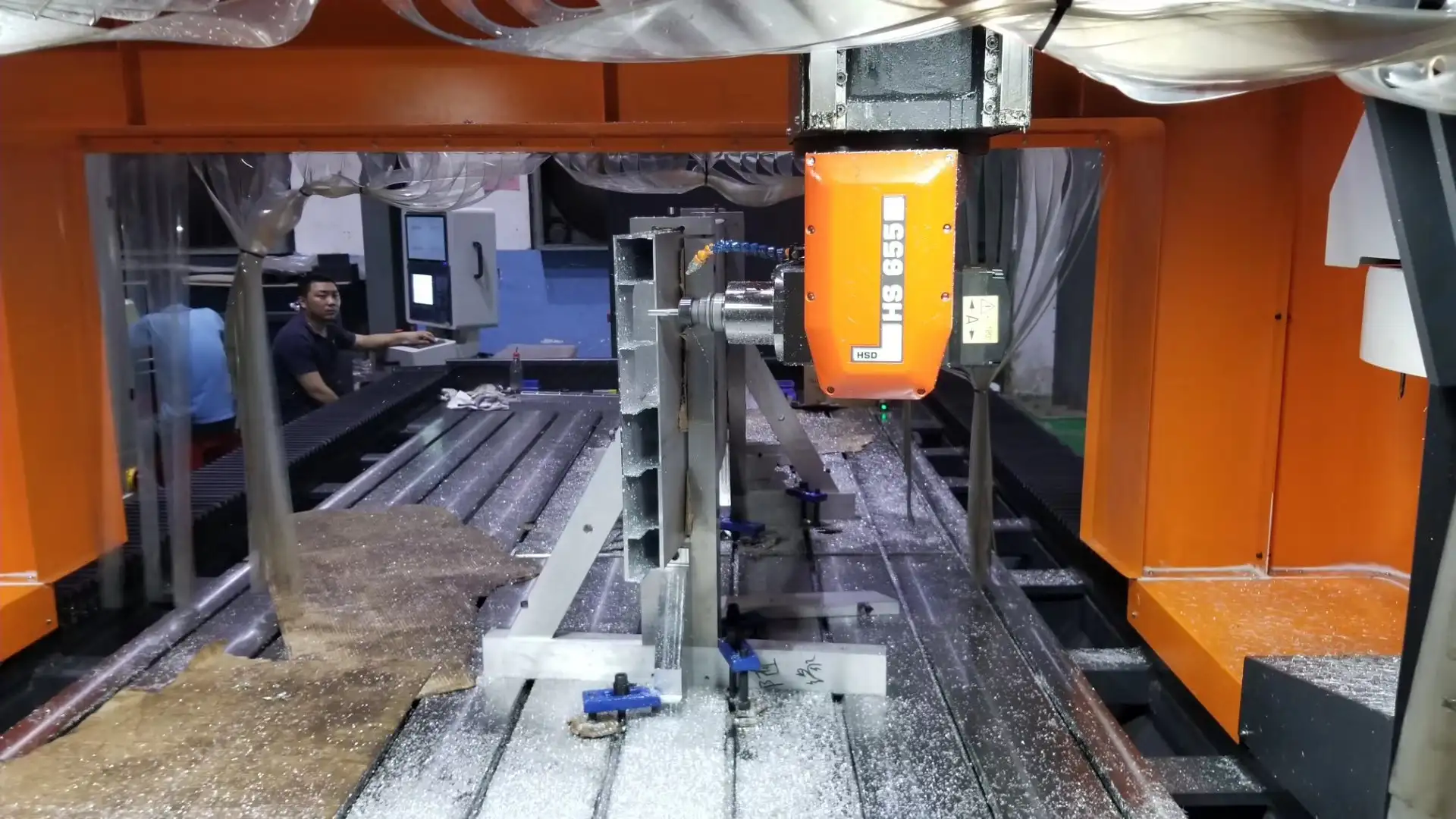

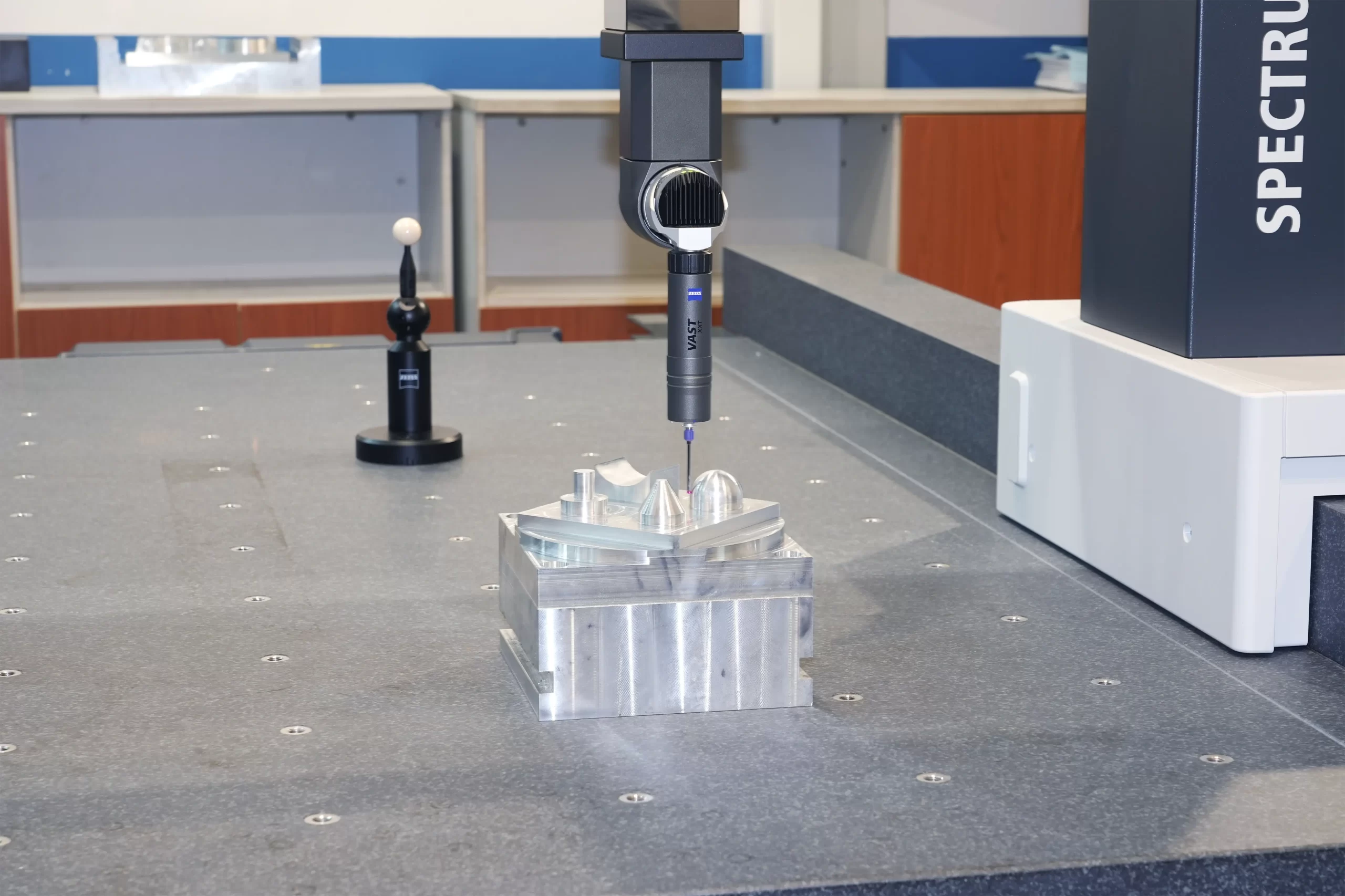

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

Advantages of Vertical Milling Machines

July 15, 2025A vertical milling machine is a type of machine tool where the spindle is oriented perpendicular to the worktable. It cuts workpieces using a rotating tool and is widely used across various machining applications. Its core strengths lie in its flexibility and precision, making it a common sight from aerospace facilities to small workshops. For… Continue reading Advantages of Vertical Milling Machines

8 Core Advantages of CNC Technology Popularization

July 14, 2025CNC (Computer Numerical Control) technology has revolutionized traditional manufacturing by precisely controlling machine tools through computer programs. It has not only boosted production efficiency but also driven innovation in product design. From aerospace to automotive manufacturing, from medical devices to personalized furniture, CNC technology is ubiquitous, and its widespread adoption is remarkable. The popularity of… Continue reading 8 Core Advantages of CNC Technology Popularization

What Is a Milling Machine? Your Essential Guide to Precision Manufacturing

July 11, 2025Milling machines are the precision shapers of modern industry. Using high-speed rotating cutters, they carve materials into components ranging from simple flats to complex 3D contours. As core equipment in aerospace, automotive, and mold-making sectors, these machines deliver unmatched accuracy, versatility, and efficiency. Milling Machine Construction and Machining Principles Core Components Think of a milling… Continue reading What Is a Milling Machine? Your Essential Guide to Precision Manufacturing

What’s a CNC System? Your Guide to Computer Numerical Control

July 10, 2025Ever wondered how those super precise parts for airplanes or cars get made? Chances are, a CNC (Computer Numerical Control) system is behind it all! This tech uses computer programs to control machine tools, making high-precision manufacturing a reality across modern industries. It all kicked off in the 1950s, driven by the needs of aerospace,… Continue reading What’s a CNC System? Your Guide to Computer Numerical Control

CNC Fabrication: Mastering Materials, Machines, and Costs for Precision Manufacturing

July 09, 2025What Is CNC Fabrication? CNC fabrication (Computer Numerical Control fabrication) uses computer-guided machines to shape parts by precisely removing material from a workpiece. G-code, a set of coded instructions, directs machines to perform tasks like CNC milling, turning, or drilling. This automation ensures exceptional accuracy and repeatability, making CNC fabrication indispensable in high-stakes industries. The… Continue reading CNC Fabrication: Mastering Materials, Machines, and Costs for Precision Manufacturing

What Is the Difference Between 3-Axis and 5 Axis Machining

July 08, 2025CNC Machining Basics What Is CNC Machining? CNC machining (Computer Numerical Control) is like giving a machine a genius brain, using software to guide tools that carve metal, plastic, or other materials with pinpoint accuracy. From turbine blades in aerospace to engine components in cars and even orthopedic implants in healthcare, CNC makes it happen.… Continue reading What Is the Difference Between 3-Axis and 5 Axis Machining

What’s Five-Axis Machining

July 07, 2025Hey, folks! Ever wonder how they make those mind-blowing parts for jets, medical gadgets, or your car’s engine? Let’s talk about five-axis machining—the rockstar of CNC (Computer Numerical Control) machining. It’s like the ultimate tool for crafting insanely complex stuff, and I’m here to break it down like we’re chilling at a barbecue. Ready to… Continue reading What’s Five-Axis Machining

What Is a Three-Axis System

July 04, 2025Basics of Three-Axis CNC Systems What Is a Three-Axis System? A three-axis system is the most fundamental and core motion control method in modern CNC machining equipment. It refers to a machine’s ability to move simultaneously along the X, Y, and Z axes. Driven by servo motors, the cutting tool or workpiece can precisely move… Continue reading What Is a Three-Axis System

How to Optimize CNC Machining Parameters to Improve Efficiency and Reduce Tool Wear

July 02, 2025Want to crank up your CNC shop’s game? Optimizing machining parameters is the secret sauce to slashing costs, boosting output, and keeping your parts top-notch. It’s all about tweaking key settings like cutting speed (Vc, measured in meters per minute, or how fast your tool’s edge zips along), feed rate (F, in millimeters per revolution,… Continue reading How to Optimize CNC Machining Parameters to Improve Efficiency and Reduce Tool Wear

What Are the Main Applications of CNC Machines

July 01, 2025Overview of CNC Machines Definition and Basic Principles CNC machines (Computer Numerical Control machines) serve as powerful workhorses in modern manufacturing, precisely controlling tools and workpieces through computer programs to complete complex machining tasks. Their core components include the spindle, cutting tools, workpiece holding systems, and control units, all driven by digital instructions that control… Continue reading What Are the Main Applications of CNC Machines

Basic Overview and Core Advantages of CNC Vertical Machining Center

July 21, 2021With the rapid development of the manufacturing industry, CNC vertical machining center (Vertical Machining Center, VMC) has become one of the key equipment in the field of precision machining. This article will introduce you to the basic structure, working principle, and core advantages of vertical machining center. Structure and working principle of CNC vertical machining… Continue reading Basic Overview and Core Advantages of CNC Vertical Machining Center

How to Choose a Suitable CNC Vertical Machining Center

July 20, 2021CNC vertical machining centers occupy an important position in modern manufacturing. However, facing the wide variety of equipment on the market, how to choose a machine tool that suits the needs of the enterprise has become a difficult problem for many users. This article will provide you with several key purchase suggestions. Select equipment specifications… Continue reading How to Choose a Suitable CNC Vertical Machining Center