FANUC Robodrill – High-Speed Tapping for 3C & Precision Parts

Fanuc Robodrill

High-Performance of Machining

- High-speed, high-precision and fine surface machining by high-rigidity machine structure and latest CNC functions

- Utilization in various fields by wide variety of spindle

- High-productivity by stable machining with thermal displacement compensation function

Maximizing Uptime

- Long-term stable operation by high-reliability, high-maintainability and preventive maintenance functions

- Reducing power consumption including peripherals by energy saving technologies Operation condition monitoring and analysis by ROBODRILL-LINK!

Ease of Use

- Excellent operability of exclusive screens with human-centered design

- Easy to connect peripherals or network by high-expandability and user-interface

- Easy integration with FANUC Robot by automation supporting functions

Key Features

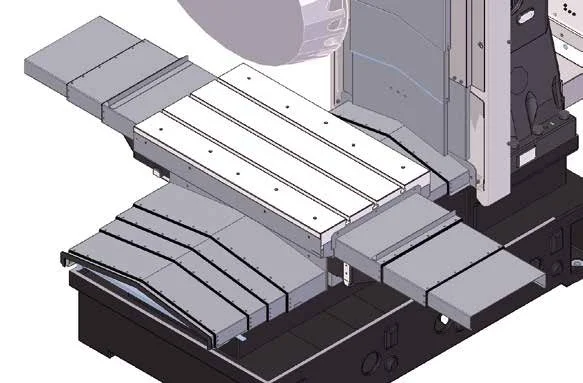

Y-axis stroke 500mm

- Stroke extension by 100mm to meet the needs of combined and large-sized parts machining.

- Table depth also extended to 500mm to accept larger fixture

- Machine length extension only by 65mm by applying multi-steps telescopic cover, etc.

- Approach from front door to table only 180mm

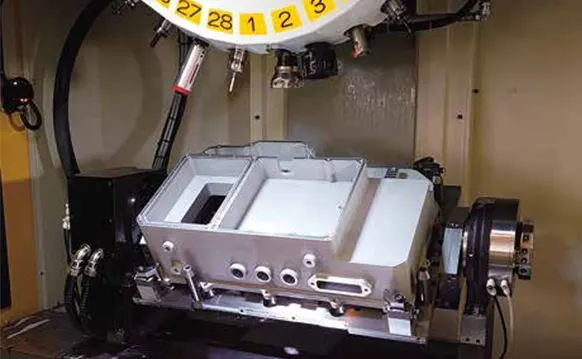

Tool storage capacity 28 tools

- Large-sized turret to enhance process integration

- Max. tool mass 4kg, Max. total tool mass 46kg

- Tool change time 0.7s(1.5kg setting, Tool to Tool)

*Option for X-axis stroke 500mm and 700mm of Advanced version

Level-up of Z-axis feed

- Rapid traverse rate 6Om/min, Max. acceleration2.2G

- Cycle time reduction in drilling and tapping

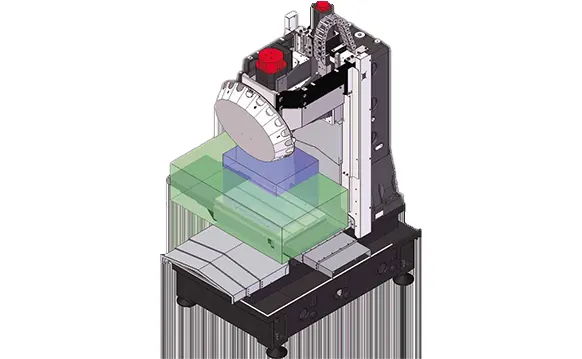

DDR-TLiB raised version(option)

- Max. turn diameter 540mm to make the most of Y-axis stroke 500mm

Expanding Application Range

Expanding machining area

- Z-axis stroke extension to 400mm improves approach tothe machining point

- Less interference structure with the large fixture

Table load capacity 400kg*

- Applicable to large fixture and workpiece

- Max 200kg for X-axis stroke 300mm

High column (option)*

- Column raising up to 400mm depending on fixtureis available for wide range of application*

- Max 200mm for Xaxs stroke 300mm

Servo turret

- Max. tool weieht 4ke enables larger cutting tool

- Tool change time reduction by O.2s compared withstandard version ROBODRILL

Automation Meets High Reliability

With seamless robot integration and rigorous reliability testing, ROBODRILL ensures both automated machining and stable long-term operation.

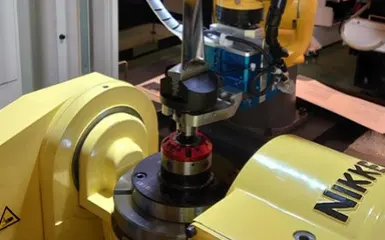

Easy Connection & Integration

Equipped with optional Robot Interface 2, enabling system start/stop, status checks, and manual robot operation directly on-screen. Easy setup links ROBODRILL to robots with FL-net for safer and cleaner wiring.

All-in-One Robot Package

The optional Robot Package includes essential components like the robot, base, automatic side door, connection cables, and sample interface programs, allowing for plug-and-play installation upon delivery.

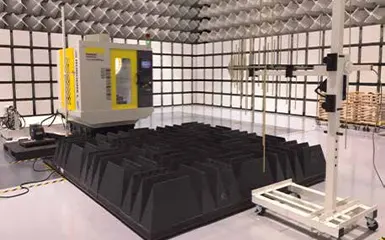

High-Standard Reliability Validation

FANUC uses proprietary accelerated life testing across various labs—anechoic chamber, EMC, and vibration test rooms—to ensure reliable operation under diverse conditions.

Factory-Proven, Data-Driven Design

Over 200 ROBODRILL units run continuously at FANUC’s in-house factory for both steel and aluminum machining. Operation and maintenance data are fed back into the design for ongoing performance and reliability improvements.

Contact Us – Start Your Smart Manufacturing Journey

Whether you’re exploring efficient automation solutions or aiming to enhance reliability and productivity, we’re here to provide tailored support and services.

Feel free to contact us anytime for more product details, application examples, or customized solution advice!