Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

Key Industries Driving the Surge in 5-Axis CNC Machine Demand

October 31, 2025From Luxury to Necessity What was once a niche capability for elite aerospace shops has become essential infrastructure across modern manufacturing. Today, 5-axis CNC machining is no longer a “nice-to-have”—it’s a strategic necessity for industries demanding high-precision machining, complex geometries, and the ability to tame difficult materials like titanium and Inconel 718. The numbers tell… Continue reading Key Industries Driving the Surge in 5-Axis CNC Machine Demand

5 Safety Rules Every CNC Operator Must Follow in 2025

October 29, 2025In today’s precision manufacturing environment, the role of a CNC operator extends far beyond pressing start buttons. As a CNC machine operator, you are responsible for safety, quality, and efficiency—all while navigating complex machinery, high-speed tools, and hazardous fluids. According to OSHA, over 20% of manufacturing injuries involve machinery, many of which could be prevented… Continue reading 5 Safety Rules Every CNC Operator Must Follow in 2025

CNC Machine Coolant: Guide to Maintenance & Savings

October 27, 2025In modern precision manufacturing, Computer Numerical Control (CNC) machines are the backbone of production. Yet one of the most overlooked—yet critical—components of these systems is CNC machine coolant. Far from being a mere auxiliary fluid, coolant works in close synergy with the spindle, feed system, toolpath, and even the CNC program itself to ensure stable,… Continue reading CNC Machine Coolant: Guide to Maintenance & Savings

Choosing Between Vertical and Horizontal Machining Center

October 23, 2025In today’s precision manufacturing landscape, the choice of a machining center isn’t just about buying a machine—it’s a strategic decision that shapes your production capacity, part quality, and long-term competitiveness. When your parts evolve from simple brackets to complex aerospace housings, or your order volumes swing from prototypes to high-volume runs, the right machine architecture… Continue reading Choosing Between Vertical and Horizontal Machining Center

CNC Machine Accuracy: Tolerance, Repeatability, And Calibration

October 22, 2025In today’s precision manufacturing landscape, CNC (Computer Numerical Control) machines are the backbone of high-consistency, high-efficiency, and high-complexity part production. From aerospace turbine blades and medical implants to critical automotive powertrain components, the quality of these parts hinges largely on the accuracy performance of the CNC machine. Yet, the term “accuracy” is often reduced to… Continue reading CNC Machine Accuracy: Tolerance, Repeatability, And Calibration

Why Aerospace CNC Demands 5-Axis Machining Centers

October 20, 20251. Introduction The aerospace industry sits at the apex of modern manufacturing—where every component must deliver micron-level precision, geometric complexity, and unwavering reliability under extreme conditions. From jet engines to satellite structures, turning visionary designs into flight-ready hardware depends on one critical enabler: the high-end CNC machining center. Conventional 3-axis machines simply can’t meet the… Continue reading Why Aerospace CNC Demands 5-Axis Machining Centers

How to Reduce CNC Machine Downtime in Production

October 17, 2025In today’s fiercely competitive manufacturing landscape, equipment uptime is a decisive factor in operational excellence. Computer Numerical Control (CNC) machines—central to precision manufacturing—must run continuously, reliably, and efficiently to meet delivery deadlines, control costs, and maintain profitability. Yet unplanned machine downtime remains one of the most persistent barriers to peak performance. According to the Association… Continue reading How to Reduce CNC Machine Downtime in Production

How to Choose the Right CNC Machine for Aluminum Parts

October 15, 2025Why Aluminum Machining Is Unique—and Why Machine Selection Matters Aluminum alloys have become one of the most widely used lightweight metals in modern manufacturing, thanks to their low density (about one-third that of steel), high strength-to-weight ratio, excellent thermal and electrical conductivity, ease of forming, and recyclability. From aerospace and electric vehicles to consumer electronics,… Continue reading How to Choose the Right CNC Machine for Aluminum Parts

CNC Machining Center vs. CNC Milling Machine: Key Differences

October 13, 2025In modern manufacturing, numerical control (NC) technology has revolutionized traditional machining processes. Among the core equipment in this transformation are CNC machining centers and CNC milling machines, both widely used across aerospace, automotive, medical device manufacturing, mold making, and precision component production. While they may look similar at first glance, these two machine types differ… Continue reading CNC Machining Center vs. CNC Milling Machine: Key Differences

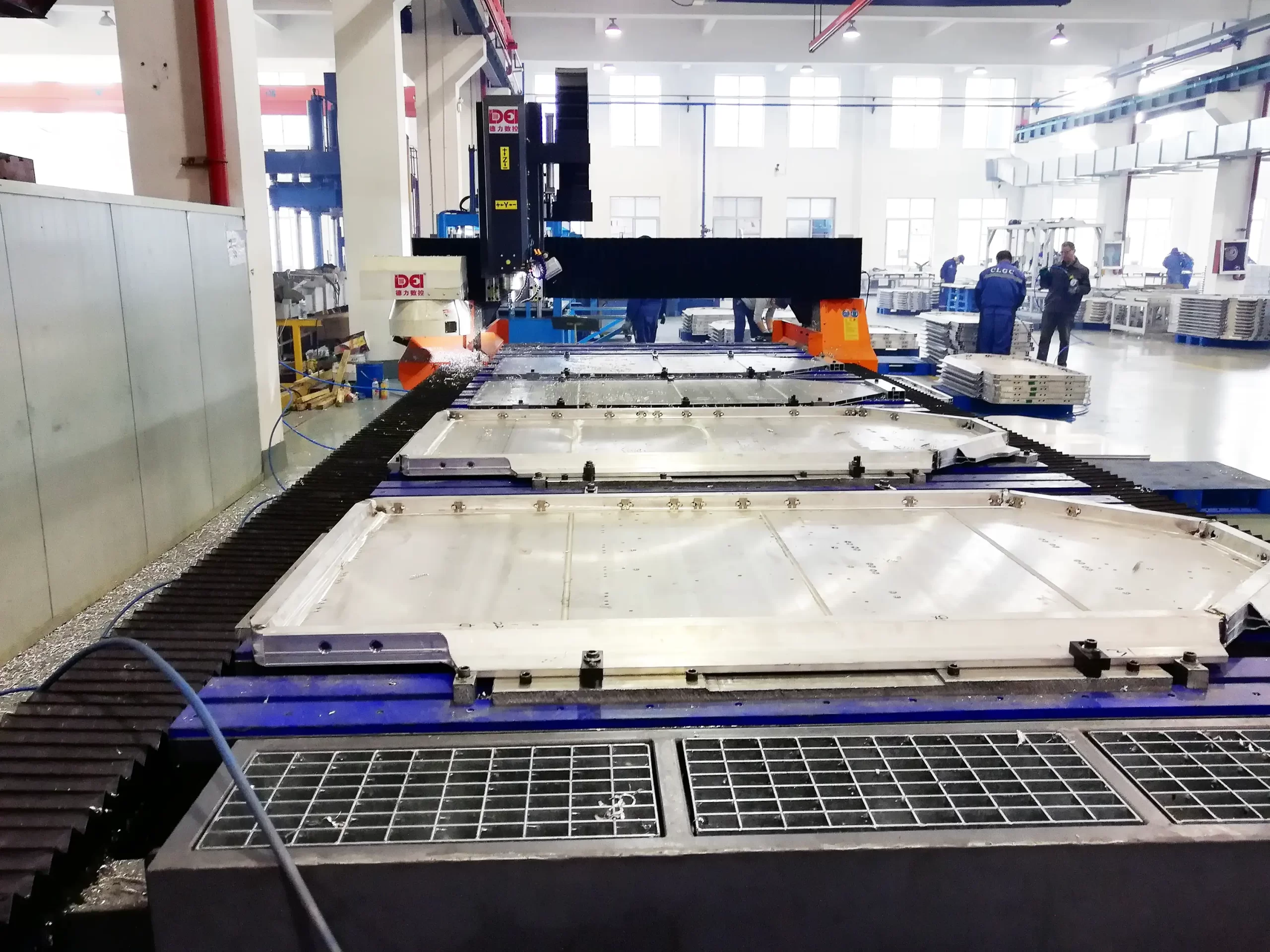

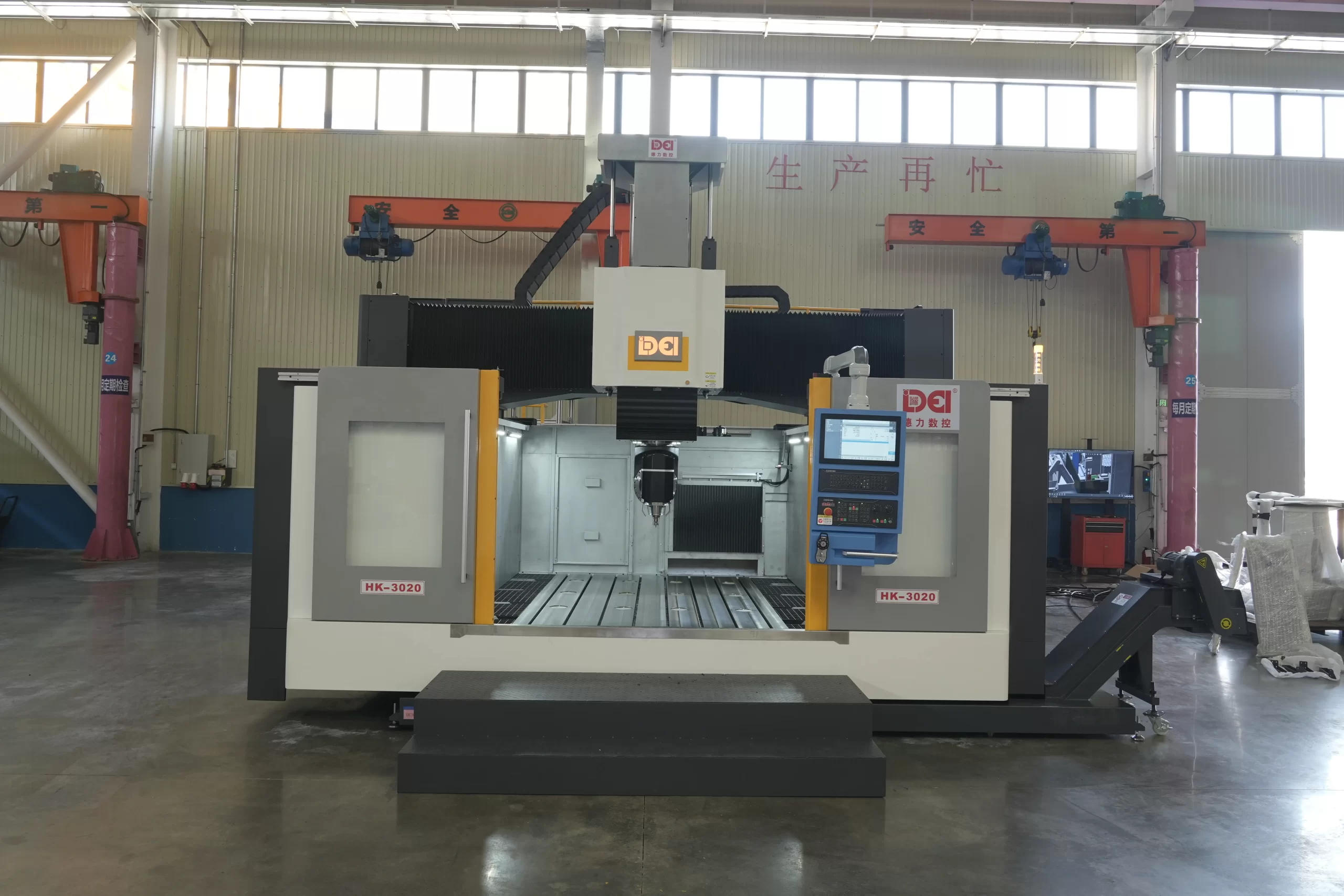

3-Axis Gantry CNC Boosts Automotive Production Efficiency

October 11, 2025You want faster, more precise automotive parts production. The MD-Z-3020 3-Axis Gantry Machining Center gives you the edge with advanced machining for small and medium batches. You can handle complex parts easily and keep your production line moving. This machine helps you reach higher efficiency and tighter tolerances, so your business stays ahead in a… Continue reading 3-Axis Gantry CNC Boosts Automotive Production Efficiency

How Does a CNC Machine Work? A Complete Guide

October 10, 2025In modern manufacturing, CNC machines (Computer Numerical Control machines) have become the backbone of high-precision, high-efficiency production. From critical aerospace components to automotive engine blocks, nearly every precision part produced in volume relies on CNC technology. Industry data shows that over 85% of metal-cutting operations worldwide are performed by CNC machines, achieving tolerances as tight… Continue reading How Does a CNC Machine Work? A Complete Guide

15 Features of the Best CNC Machines for Small Businesses

October 09, 2025In today’s fiercely competitive manufacturing landscape, small businesses—typically those with under $5 million in annual revenue and fewer than 20 employees—are under constant pressure to do more with less. CNC machines have become essential for boosting productivity, ensuring consistent quality, and expanding service offerings. But here’s the catch: for a small shop, buying a CNC… Continue reading 15 Features of the Best CNC Machines for Small Businesses