What’s a CNC System? Your Guide to Computer Numerical Control

Ever wondered how those super precise parts for airplanes or cars get made? Chances are, a CNC (Computer Numerical Control) system is behind it all! This tech uses computer programs to control machine tools, making high-precision manufacturing a reality across modern industries. It all kicked off in the 1950s, driven by the needs of aerospace, and has evolved from clunky punch cards to the smart platforms we see today. The result? A massive leap in both machining efficiency and accuracy.

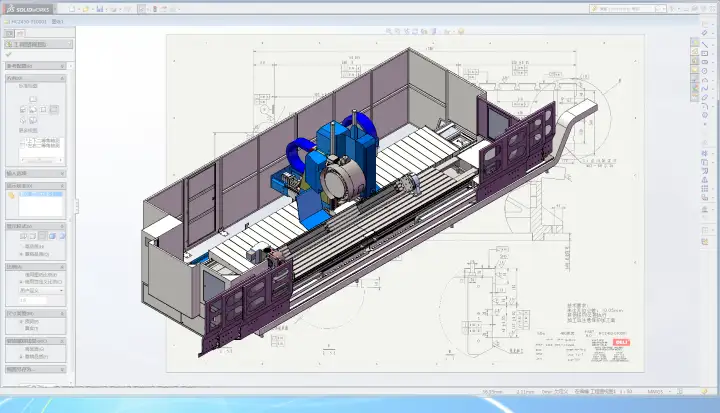

At its heart, CNC relies on CAD/CAM software to whip up machining instructions. These instructions then drive the machine tools to perform automated operations, often with an incredible error margin of just 1-5 micrometers. Thanks to its high precision, flexibility, and automation, CNC is perfect for tackling complex part manufacturing in fields like aerospace, automotive, and medical. It helps shorten production cycles and ensures consistent quality, every single time. Just a heads-up though: CNC isn’t here to completely replace human workers. Instead, it cuts down on repetitive labor, but you’ll still need skilled pros to handle the programming and maintenance. It’s all about smart collaboration!

How It Works

So, how does a CNC system actually do its magic? It’s a pretty streamlined process, usually broken down into three main stages: design, programming, and execution.

1. Design Stage (CAD)

Everything kicks off with creating a digital design of the part you want to make using Computer-Aided Design (CAD) software. Engineers and designers get to work, crafting detailed 2D or 3D models. They define all the precise dimensions, geometry, and features of the part. Think of it as drawing up the blueprint, but on a computer!

2. Programming Stage (CAM, G-code, M-code)

Once that CAD model is looking perfect, it’s time to translate it into a language the CNC machine can understand. This is typically done with Computer-Aided Manufacturing (CAM) software. CAM software generates specific machine language, and here’s where G-code and M-code come into play:

- G-code: This is the geometric code that tells the machine where to move (like X, Y, and Z coordinates), how fast to move (feed rate), and the exact path the cutting tool needs to follow.

- M-code: These are the miscellaneous codes that control various machine functions. We’re talking about things like turning the spindle on or off, initiating a tool change, or activating the coolant. Together, these codes form a precise sequence of commands that guide every aspect of the machining process.

3. Execution Stage

Finally, the generated G-code and M-code are loaded into the CNC machine’s Machine Control Unit (MCU). You can think of the MCU as the

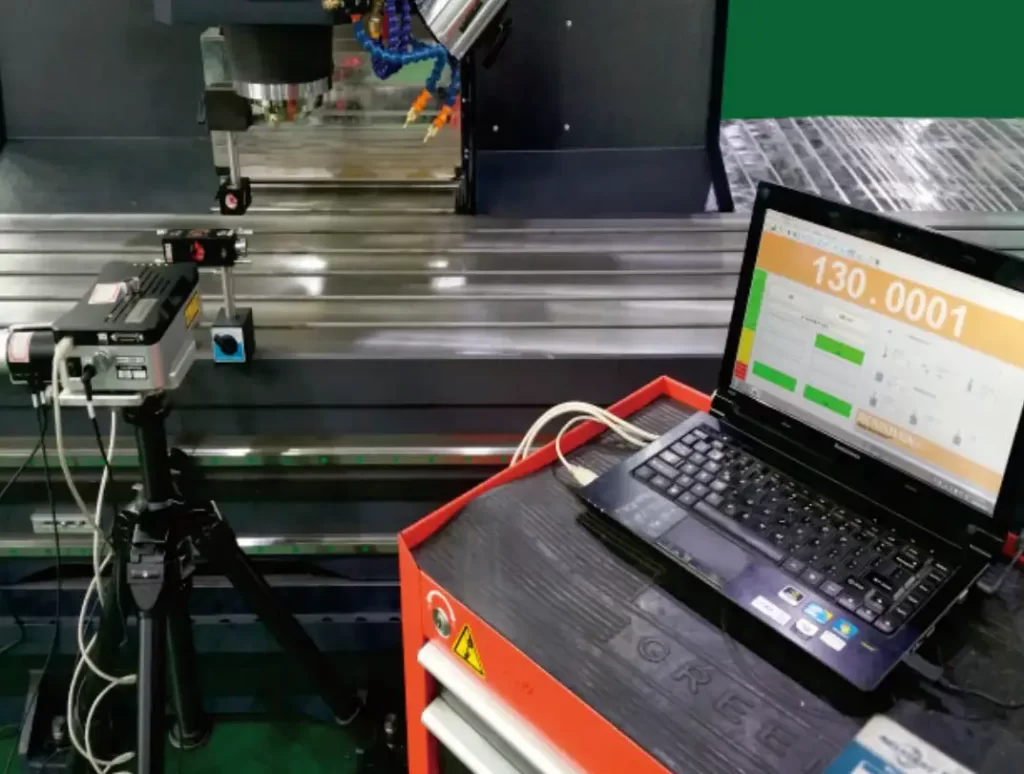

‘brain’ of the system. The MCU interprets these instructions and converts them into electrical signals that control the machine’s motors and other components. The machine then executes these commands, precisely controlling the movement of the cutting tool to shape the workpiece. Advanced CNC systems often include feedback mechanisms, like sensors and encoders, to make sure the actual tool position matches the programmed position. This is how they guarantee such high precision!

System Types

Not all CNC systems are created equal! They come in different flavors, each designed for specific types of machining tasks. Let’s dive into the main categories:

1. Point-to-Point Control Systems

Point-to-point control systems are all about getting the tool or workpiece from one precise spot to another, quickly and accurately, without worrying about the path it takes in between. These systems are perfect for machining jobs that need high-precision positioning but don’t require continuous path control.

Core Features:

- Pinpoint Positioning: They use coordinate commands (like X, Y, Z) to achieve rapid point-to-point movement, with positioning accuracy often reaching micrometer levels.

- Path Independent: The system doesn’t control the tool’s movement trajectory, which simplifies the control algorithms.

- Efficient and Simple: These systems are compact, respond super fast, and are ideal for high-frequency, repetitive positioning tasks.

Typical Applications:

- Drilling and spot welding in circuit board manufacturing.

- Positioning tasks on automated assembly lines.

- Simple stamping or spot riveting operations.

Advantages and Limitations:

Point-to-point control systems are widely used in small and medium-sized processing equipment because they’re simple to design and cost-effective. However, they can’t handle complex curve machining, which limits their use in high-precision continuous path scenarios.

2. Contouring Control Systems

Contouring control systems are specifically designed for machining complex curves and surfaces. They use interpolation algorithms to precisely control the tool’s movement along a continuous path, ensuring a smooth surface finish and accurate dimensions. These systems support multi-axis联动 (simultaneous movement), making them suitable for manufacturing highly complex parts.

Core Features:

- Interpolation Algorithms: They generate smooth tool paths using linear, circular, or spline interpolation.

- Multi-Axis Simultaneous Movement: These systems coordinate the movement of multiple axes (like X, Y, Z, and more) to support 3D geometric machining.

- High-Precision Control: By integrating with CAD/CAM software, they optimize tool trajectories to meet strict tolerance requirements.

Typical Applications:

- Aerospace parts, such as turbine blades and curved fuselage components.

- Automotive mold manufacturing, including car body panels and complex stamping dies.

- Surface milling of precision mechanical parts.

Advantages and Limitations:

Contouring control systems excel at complex geometric machining, offering high precision and excellent surface quality. However, they demand more sophisticated control systems and machine performance, which also means a higher cost.

3. Hybrid Control Systems

Hybrid control systems combine the best of both point-to-point and contouring control. They support multi-axis simultaneous movement and turn-mill composite machining, making them ideal for complex machining needs that require high flexibility and efficiency. By integrating various machining functions, these systems significantly boost production efficiency.

Core Features:

- Multi-Axis Simultaneous Movement: They support five-axis or even more simultaneous movements, adapting to the machining of complex 3D parts.

- Turn-Mill Composite Machining: These systems can complete multiple processes like turning and milling in a single setup, reducing errors from re-positioning the workpiece.

- Flexible Programming: They use advanced CAM software to generate composite instructions, optimizing the entire machining process.

Typical Applications:

- Complex parts in high-end manufacturing, such as turbine blades and aero-engine components.

- Medical device manufacturing, like the precision machining of orthopedic implants.

- Multi-process integrated machining, such as the production of automotive gearbox parts.

Advantages and Limitations:

Hybrid control systems are known for their high flexibility and efficiency, especially for small-batch, multi-variety production. However, they involve complex equipment, require advanced programming skills, and come with higher initial investment and maintenance costs.

Core Components

So, what makes up a CNC system? It’s a combination of several key parts working together seamlessly:

- CNC Controller: This is truly the ‘brain’ of the system. It’s made up of a CPU and memory, and its job is to interpret the G-code and coordinate the machine’s operations. The control software provides a user-friendly interface, supports path planning, and even helps with remote fault diagnosis. Pretty smart, right?

- Servo System: Think of this as the powerhouse. It includes servo motors, drivers, and power amplifiers. AC servo motors are super efficient and low-maintenance, precisely controlling the position of the tool or workpiece to meet those micrometer-level machining demands.

- Feedback and Detection Devices: These are the ‘eyes’ of the system. Encoders capture position data, while temperature and vibration sensors monitor the machine’s status. Closed-loop control uses this real-time feedback to correct errors, making it much more accurate than open-loop control.

- Auxiliary Systems: These systems optimize the machining environment. For example, cooling and lubrication systems reduce thermal deformation, and tool management systems automatically monitor tool wear and switch tools when needed. All of this helps keep production running smoothly and efficiently.

Application Areas

CNC technology is a true game-changer, and you’ll find it making a huge impact across a ton of different industries. Let’s check out some of the big ones:

Manufacturing

When it comes to metal cutting and mold making, CNC is absolutely essential. In metal cutting, G-code guides the tools to produce mechanical parts with incredible micrometer-level precision. For mold making, CNC uses complex paths to machine plastic injection molds, meeting the demands of industries like home appliances and toys. For instance, FANUC CNC systems have been known to shorten mold processing cycles by a whopping 20%!

Aerospace

The aerospace industry has super strict requirements for part precision, and that’s where multi-axis CNC technology shines. It’s used to machine the complex curved surfaces of turbine blades, ensuring stable performance. When working with composite materials like carbon fiber, CNC optimizes cutting parameters to prevent delamination, which is crucial for maintaining the structural integrity of aircraft components.

Automotive Industry

CNC is a major driving force behind the efficient production of engine parts and car body molds. Turn-mill composite machining precisely manufactures cylinder blocks and crankshafts, minimizing errors. And for car body molds, CNC ensures those sleek, streamlined panels have a perfect surface finish, boosting both the vehicle’s appearance and assembly quality.

Other Industries

CNC shows off its flexibility in a variety of other fields, including medical, electronics, and even wood and stone processing. In the medical sector, it’s used to machine high-precision components like artificial joints, ensuring a perfect fit for the human body. The electronics industry relies on CNC to produce phone casings and circuit board molds, meeting the demands for tiny, intricate parts. And for woodworking and stone processing, CNC is used to carve complex patterns or cut large marble slabs. Pretty cool, right?