What Is the 2:1 Rule for Linear Bearings

In linear motion systems, linear bearings ensure smooth, precise movement in applications like CNC machines and automated production lines. Whether designing a high-precision CNC router or troubleshooting a linear bearing rail system, proper bearing placement is critical. The 2:1 rule is a key design principle that prevents jams and keeps your linear bearing system gliding effortlessly.

This article explores the 2:1 rule, its importance, and how to apply it to linear bearing systems like CNC spindles or heavy-duty rails. We include real-world examples for practical understanding.

What Are Linear Bearings?

Linear bearings minimize friction and support loads, enabling precise motion in equipment like robotic arms and CNC machines. Without reliable linear bearing rails, systems may wobble or seize up.

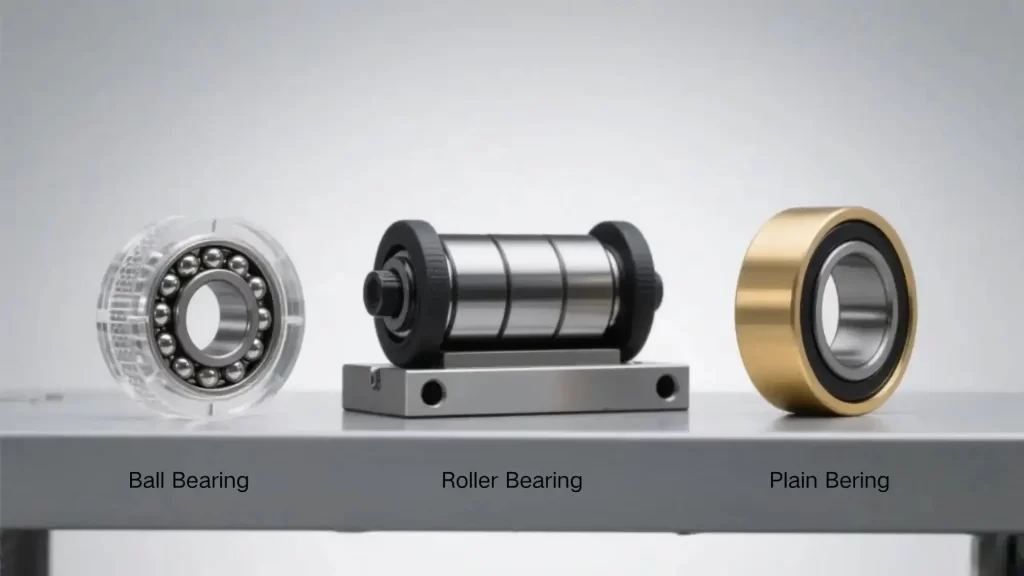

Here’s a rundown of common linear bearing types:

| Bearing Type | How It Works | Advantages | Applications |

|---|---|---|---|

| Ball bearings | Steel balls roll to cut friction | High precision, low friction, fast | CNC spindles, precision tools |

| Roller bearings | Rollers handle heavy loads | High load capacity, durable | Industrial slides, heavy machinery |

| Plain bearings | Lubricated surfaces slide, no rollers | Simple, dust-resistant, great for low speeds | Rugged rails in harsh environments |

Linear bearings are vital in CNC machines for micron-level spindle precision, in automation for smooth conveyor and arm movement, and in robotics for stable joints. Learn more about motion system components.

Real-World Example: A CNC shop switched to linear ball bearings for their rail system, improving high-speed cut precision and reducing scrap rates.

Understanding the 2:1 Rule for Linear Bearings

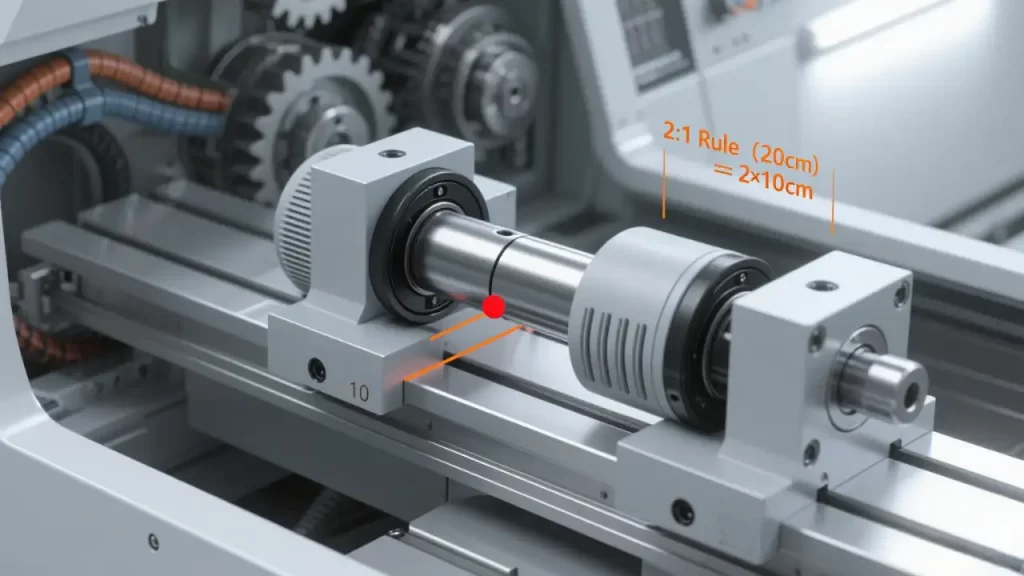

The 2:1 rule is a cornerstone for designing linear bearing systems. It states that the distance between two bearings should be at least twice the distance from the nearest bearing to the load’s center of gravity. For example, if a CNC spindle’s center of gravity is 10 cm from the closest linear bearing slide, bearings should be at least 20 cm apart.

This setup evenly distributes the load across linear bearing rails, preventing tipping or binding. Binding can halt systems, damage workpieces, and increase costs. The 2:1 rule ensures smooth linear bearing motion and extends component life.

Quick Formula: If the distance to the load’s center of gravity is D, bearing spacing should be ≥2D.

Why the 2:1 Rule Enhances Linear Bearing Performance

The 2:1 rule prevents binding in linear bearing slides, ensuring seamless operation in tasks like CNC machining. Misaligned bearings can cause jams, ruining workpieces and disrupting schedules. Proper spacing maintains stability.

The rule also extends the life of linear bearing rails and bearings by reducing stress through even load distribution. In heavy-duty systems, this stability is critical. Industry estimates suggest well-designed linear bearing systems can cut maintenance costs by up to 20% by reducing replacements and downtime.

Real-World Example: An automation line adjusted linear bearing spacing to meet the 2:1 rule, reducing downtime from 10 hours a month to 2, boosting productivity. Explore more on automation efficiency.

Applying the 2:1 Rule in Linear Bearing System Design

Implementing the 2:1 rule requires planning but delivers reliable linear bearing performance. Here’s a practical guide and key considerations.

How to Apply the 2:1 Rule

- Locate the Load’s Center of Gravity: Use CAD or manual measurements to find the distance (D) from the load (e.g., a CNC spindle) to the nearest slide.

- Set Bearing Spacing: Space linear bearings at least 2D apart. For example, if D is 5 cm, bearings should be at least 10 cm apart.

- Check Rail Length: Ensure rails support the spacing and travel range.

- Verify Load Distribution: Use simulation tools to confirm even load spread across linear bearings.

- Test and Tweak: Test slides for smooth motion. If binding occurs, adjust spacing or setup.

Key Factors for Linear Bearing Design

- Load Size: Heavy loads, like industrial CNC spindles, need robust linear bearings and wider spacing.

- Bearing Type: Linear ball bearings suit high-speed, high-precision tasks; roller bearings excel in heavy-duty systems.

- Rail Length: Short rails may limit spacing, requiring design tweaks.

- Environment: Dust or heat can affect linear bearing performance. Pillow bearings handle dust but need lubrication. See bearing maintenance tips.

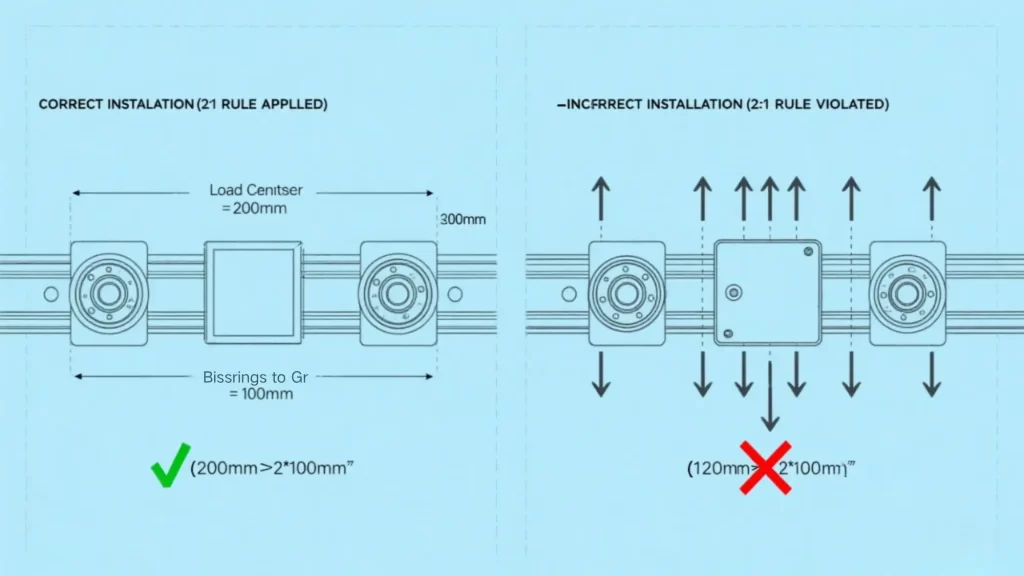

Right vs. Wrong Examples

- Right: A CNC spindle’s center of gravity is 8 cm from the nearest slide. Bearings are 16 cm apart, meeting the 2:1 rule, ensuring smooth cuts and even rail wear.

- Wrong: An automation line’s load is 10 cm from the nearest linear bearing, but bearings are 12 cm apart. Frequent jams cause uneven wear and repairs.

Visual Aid: Picture a rail system like a seesaw. If the load’s center is too close to one bearing and spacing is off, the slide binds. The 2:1 rule keeps it balanced.

Exceptions and Limitations of the 2:1 Rule

The 2:1 rule is a strong foundation for linear bearing systems, but it’s not universal. Knowing when to adapt is key.

When the 2:1 Rule Falls Short

Short-travel systems may have rails too short for 2:1 spacing. Dovetail slides, relying on sliding surfaces, have different friction dynamics, making the rule less relevant. Some heavy-duty linear bearing systems have manufacturer-specific spacing guidelines that outperform the 2:1 rule.

Workarounds for Complex Linear Bearing Cases

- Short-Travel Systems: Use a wider linear bearing slide for more contact area and stability.

- Dovetail Systems: Enhance lubrication or surface treatments to reduce binding.

- Complex Loads: Add support points, like a middle slide, or reinforce the spindle assembly.

- Consult Experts: Refer to linear bearing manufacturer guides or consult engineers for tailored solutions. Check manufacturer resources.

Real-World Example: A small robot with a short-travel rail couldn’t meet the 2:1 rule. A wider linear ball bearing improved stability without extending the rail.

Why Testing Linear Bearing Systems Matters

Testing is critical, whether using the 2:1 rule or a workaround. Run load tests to ensure linear bearing slides move smoothly. Use force sensors to verify even load distribution. Account for dust or temperature swings. If issues arise, adjust spacing, lubrication, or bearing type. Skipping tests risks spindle failures or automation breakdowns, increasing costs.

Conclusion

The 2:1 rule is a cornerstone of linear bearing system design, ensuring smooth operation, minimizing binding, extending component life, and reducing maintenance costs. Whether building a CNC router or optimizing an automation line, this rule avoids pitfalls and maintains stability. Even in short-travel or dovetail systems, its load-balancing principle holds true.

Ignoring the 2:1 rule risks jammed slides, worn rails, or spindle failures, leading to costly downtime. Prioritize the rule, consider load size, bearing type, and environment, and test rigorously. For complex projects, consult manufacturer guides or engineers. With the 2:1 rule and smart planning, your linear bearing system will deliver precision and durability.