CNC Fabrication: Mastering Materials, Machines, and Costs for Precision Manufacturing

What Is CNC Fabrication?

CNC fabrication (Computer Numerical Control fabrication) uses computer-guided machines to shape parts by precisely removing material from a workpiece. G-code, a set of coded instructions, directs machines to perform tasks like CNC milling, turning, or drilling. This automation ensures exceptional accuracy and repeatability, making CNC fabrication indispensable in high-stakes industries.

The process starts with CAD software, where engineers design 2D or 3D models with exact dimensions and tolerances. CAM software then converts these designs into G-code, orchestrating the machine’s movements. For example, in CNC aerospace fabrication, titanium parts can be crafted with tolerances as tight as ±0.01 mm for flawless assembly.

CNC fabrication is highly versatile, producing everything from basic bolts to complex turbine blades. Its speed supports rapid prototyping, and its scalability suits both custom small batches and large-scale production. For instance, an aerospace firm used precision CNC fabrication services to build an engine prototype in just 48 hours, accelerating design validation. It handles metals, plastics, wood, and composites, catering to diverse industry needs.

Core Components of CNC Fabrication

CNC fabrication relies on the seamless interplay of several key elements.

1. Machine Types

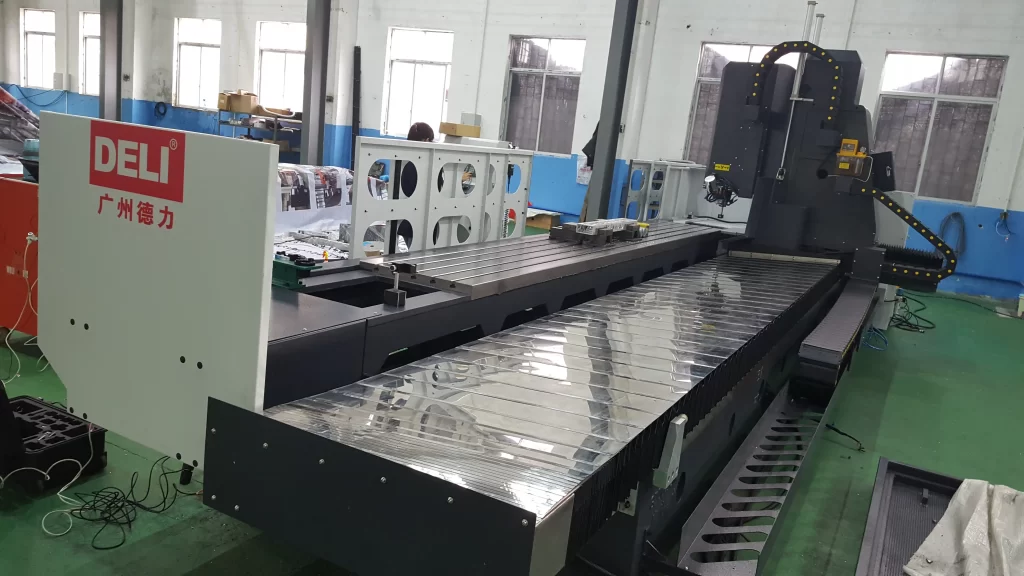

Different machines are tailored to specific CNC fabrication tasks:

- CNC Milling Machines: Rotating multi-point tools create intricate 3D shapes, ideal for molds and precision parts.

- Lathes: Spin the workpiece against a fixed tool to produce cylindrical components like shafts or bolts.

- Routers: Cut softer materials like wood or plastic, perfect for engraving and decorative designs.

- Plasma Cutters: Use high-temperature plasma to slice through thick metal efficiently.

2. Software Systems

Software powers the intelligence behind CNC fabrication:

- CAD Software: Engineers create precise part models, defining dimensions and tolerances.

- CAM Software: Translates designs into G-code, optimizing tool paths to reduce waste by up to 20%.

- CNC Control Software: Executes G-code in real time, monitors machine performance, and enables operator oversight.

3. Material Compatibility

CNC fabrication works with a wide range of materials, each requiring specific approaches:

- Metals: Aluminum, steel, and titanium; titanium demands slower cutting speeds to extend tool life.

- Plastics: ABS and polycarbonate require careful heat control to avoid warping.

- Wood: Easy to fabricate but needs precision for detailed patterns.

- Composites: Carbon fiber requires specialized tools due to its abrasive properties.

Material Selection Tip: Aerospace favors titanium for its strength-to-weight ratio, while consumer products often use cost-effective plastics in CNC fabrication.

CNC Fabrication Processes

Subtractive Manufacturing

Subtractive methods in CNC fabrication shape parts by removing material:

- CNC Milling: Rotating tools carve complex contours, widely used for molds.

- Turning: Spinning workpieces produce cylindrical parts like shafts.

- Drilling: Creates precise holes for fasteners or fluid channels.

These techniques deliver micron-level accuracy across various materials.

Additive Manufacturing

Though not core to CNC fabrication, 3D printing (e.g., FDM) applies CNC principles to control nozzle movements, ideal for rapid prototyping.

Advanced Cutting Techniques

- Laser Cutting: High-energy lasers cut thin metals with pinpoint precision.

- Plasma Cutting: Fast and effective for thick metal plates.

- Waterjet Cutting: Cold cutting with no heat distortion, versatile for multiple materials.

Comparison of Advanced Cutting Techniques

Here’s how advanced cutting methods in CNC fabrication stack up:

| Technique | Materials | Precision | Speed | Advantages | Limitations |

|---|---|---|---|---|---|

| Laser Cutting | Thin metals, plastics | High (±0.1 mm) | Fast | Precise, non-contact | Less effective for thick materials |

| Plasma Cutting | Thick metals | Medium (±0.5 mm) | Very Fast | Cost-effective for thick plates | Larger heat-affected zone |

| Waterjet Cutting | Metals, composites, wood | High (±0.1 mm) | Moderate | No heat distortion, versatile | Higher maintenance costs |

CNC Fabrication Workflow

CNC fabrication follows a streamlined process from design to quality assurance.

1. Design Phase

Engineers use CAD software to create precise models. For example, medical implants require tolerances of ±0.005 mm for biocompatibility.

2. Programming Phase

CAM software converts designs into G-code, optimizing tool paths to cut material waste by up to 30%.

3. Machine Setup

- Workpiece Fixturing: Secure clamping prevents vibration.

- Tool Selection: Carbide tools for steel; high-speed steel for aluminum.

- Calibration: Aligns tool and workpiece coordinates.

4. Execution and Quality Control

The machine runs G-code automatically, with operators monitoring tool wear. Quality checks use calipers or coordinate measuring machines (CMM) to ensure tolerances are met.

Applications of CNC Fabrication

CNC fabrication shines across industries:

- Aerospace: Produces turbine blades with micron-level precision.

- Automotive: Crafts engine blocks and molds for mass production.

- Medical: Creates surgical tools and implants with biocompatibility.

- Consumer Goods: Designs sleek device casings and decorative components.

Prototyping and Production

- Rapid Prototyping: Validates designs quickly.

- Mass Production: Automated G-code ensures consistency.

Benefits and Limitations of CNC Fabrication

Benefits

- Precision: Tolerances as tight as ±0.001 mm.

- Repeatability: Ideal for high-volume production.

- Versatility: Handles complex geometries and diverse materials.

- Efficiency: Automation cuts labor costs.

- Cost-Effectiveness: Optimized tool paths reduce material waste.

Limitations

- High Initial Costs: Five-axis machines can cost millions.

- Skill Requirements: Demands expertise in programming and operation.

- Material Constraints: Ultra-hard materials pose challenges.

- Maintenance Downtime: Regular upkeep may disrupt production.

Tips for Optimizing CNC Fabrication

1. Material Selection

Balance strength, weight, and cost. Aerospace prefers titanium; consumer goods favor plastics for affordability.

2. Machine Selection

Three-axis machines suit simple parts; five-axis machines tackle complex geometries in CNC fabrication.

3. Cost Management

- Use coated tools to extend tool life by 30%.

- Optimize machining time to lower energy costs.

- Schedule regular maintenance to minimize downtime.

4. Quality Control

Employ CMM for micron-level inspections to ensure precision CNC fabrication services meet standards.