What Is a Milling Machine? Your Essential Guide to Precision Manufacturing

Milling machines are the precision shapers of modern industry. Using high-speed rotating cutters, they carve materials into components ranging from simple flats to complex 3D contours. As core equipment in aerospace, automotive, and mold-making sectors, these machines deliver unmatched accuracy, versatility, and efficiency.

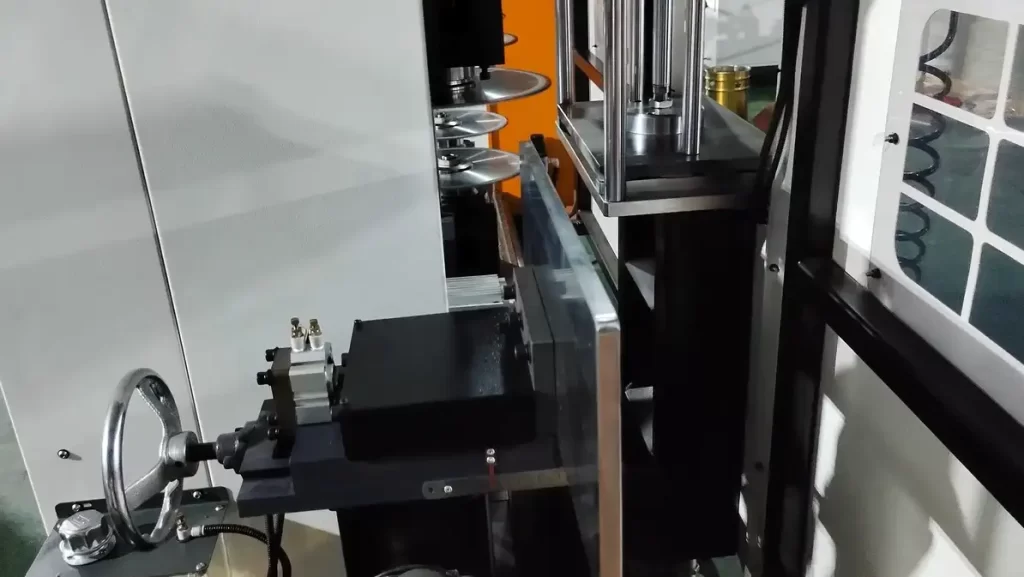

Milling Machine Construction and Machining Principles

Core Components

Think of a milling machine as a coordinated precision system:

- Machine Bed: This cast-iron foundation absorbs vibrations and ensures stability.

- Spindle: The rotating “heart” driving cutters at 500-20,000 RPM.

- Worktable: Moves along X/Y/Z axes (±0.01mm accuracy) to position workpieces.

- Feed System: Uses servo motors for micron-level movement control.

- Cooling System: Sprays fluid to reduce heat and clear chips.

- ATC (Automatic Tool Changer): Swaps tools in seconds on advanced models.

How Milling Works

Essentially, rotating multi-edge cutters remove material while the workpiece moves along programmed paths. Two primary methods exist:

- Climb Milling: Tool rotation matches feed direction. Result: Smoother finishes, ideal for final passes.

- Conventional Milling: Tool opposes feed direction. Result: Higher cutting force, better for roughing.

Optimize these parameters for your material:

| Parameter | Impact | Example Settings |

|---|---|---|

| Cutting Speed | Surface finish, tool wear | Aluminum: 150-200 m/min |

| Feed Rate | Machining time, chip thickness | Finishing: 0.01 mm/rev |

| Depth of Cut | Material removal rate | Steel: ≤1 mm/pass |

Warning: Incorrect settings cause rough surfaces or tool damage.

Types and Applications of Milling Machines

Machine Types Compared

- Vertical Mills: Compact spindle-perpendicular-to-table design. Best for: Electronics housings.

- Horizontal Mills: Spindle parallel to table. Best for: Heavy bases/gearboxes.

- CNC Mills: Computer-controlled (±0.005mm precision). Best for: Complex aircraft parts.

- Universal Mills: Adjustable spindles/tables. Best for: Curved surfaces.

- Machining Centers: All-in-one milling/drilling. Best for: High-volume production.

Top 5 Cutting Tools

- End Mills: General-purpose slotting/finishing

- Slot Drills: Deep grooves/mold cores

- Ball Nose Cutters: 3D contours (e.g., turbine blades)

- Face Mills: Rapid surface leveling

- T-Slot Cutters: Workholding fixtures

Key Industries Served

- Aerospace: Titanium engine components

- Automotive: Engine blocks (50,000+ units/year)

- Medical: Stainless steel joint implants

- Mold & Die: Injection molding cavities

- Energy: Turbine blade profiling

Selection, Operation & Maintenance Guide

Choosing Your Machine

Follow this decision framework:

- Part Size: Small? Pick vertical mills. Large? Choose horizontal.

- Precision Needs: ±0.1mm? Manual OK. ±0.01mm? Require CNC.

- Budget Range:

- Manual: ¥50,000-150,000

- CNC: ¥200,000+ Tip: Factor in tooling/fixture costs (15-20% extra).

Safe Operation Protocol

- Always wear ANSI-rated goggles and gloves.

- Verify workpiece clamping force exceeds cutting forces.

- Program CNC units using CAM software (e.g., Fusion 360).

- Immediately stop if vibration/chatter occurs.

Pro Maintenance Schedule

| Frequency | Task | Benefit |

|---|---|---|

| Daily | Clean chips/lubricate guides | Prevents accuracy drift |

| Monthly | Replace coolant/filters | Avoids corrosion |

| Quarterly | Calibrate spindle/axes | Maintains ±0.01mm tolerance |

Pro Tip: Modern CNCs self-diagnose 80% of faults via IoT sensors.

Conclusion & FAQs

Ultimately, milling machines enable mass production of precision parts unreachable by other methods. Future trends include AI-driven optimization and eco-coolants.

Frequently Asked Questions

Q: Milling machine vs. lathe?

A: Mills rotate tools on stationary workpieces (flats/contours). Conversely, lathes rotate workpieces against tools (cylinders/shafts).

Q: Is CNC operation difficult?

A: Basic functions take 1-2 weeks to learn. However, mastering G-code/CAM requires 3-6 months.

Q: How to select cutters?

A: Follow this guide:

- Hard materials (steel): Carbide-coated tools

- Soft materials (aluminum): High-speed steel

- Curved surfaces: Ball nose end mills

Q: Maintenance complexity?

A: Surprisingly simple: Daily cleaning (10 mins) and quarterly calibrations prevent 90% of issues.