What Is a CNC Machinist

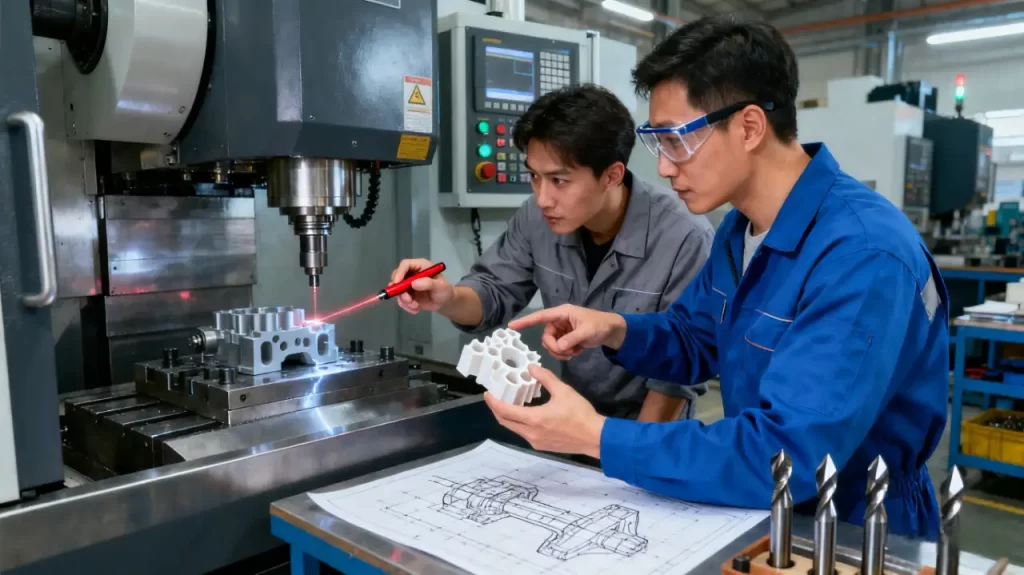

In today’s world of smart factories and digital manufacturing, the CNC machinist stands at the powerful intersection of code and metal — turning 3D models into real-world parts with tolerances thinner than a human hair.

Forget the outdated “button-pusher” stereotype. Modern CNC machinists don’t just run machines — they optimize processes, troubleshoot first-article failures, fine-tune cutting parameters, and act as the final quality checkpoint before parts ship.

According to the U.S. Bureau of Labor Statistics (BLS, 2023):“CNC machinists set up and operate computer numerically controlled (CNC) machine tools to cut, drill, mill, or turn workpieces according to engineering drawings or CAM-generated programs — ensuring parts meet dimensional, geometric, and surface finish requirements.”

In China’s National Occupational Classification Dictionary (2022), the role is still labeled “6-18-01-02 CNC Machine Operator.” But in reality? That title hasn’t kept up with the job. Today’s CNC machinists are hybrid technicians — part programmer, part engineer, part quality inspector.

Think of them as: Program Executor — Running G-code with precision Process Optimizer — Tweaking feeds, speeds, and setups for max efficiency Quality Gatekeeper — Measuring, validating, and preventing scrap

Which Industries Hire CNC Machinists?

You’ll find CNC machinists everywhere precision matters:

- Aerospace & defense

- Medical device manufacturing

- Electric vehicle (EV) components

- Robotics & automation systems

- Mold & die shops

- Smart factory production lines

With Industry 4.0 accelerating and global supply chains demanding local precision manufacturing, CNC machinist demand is surging — especially in high-tech sectors. These professionals are the “last-mile executors” of digital design — and their value is climbing fast.

Top CNC machinists don’t just produce parts — they reduce cycle times, boost OEE (Overall Equipment Effectiveness), and lead process standardization efforts. In smart factories, they’re often the bridge between engineering, programming, and production.

What Does a CNC Machinist Actually Do?

Let’s clear up the confusion. Many people mix up CNC machinist, CNC operator, and CNC programmer. Here’s how they really differ:

| Role | Core Responsibility | Key Competencies | Works Independently |

|---|---|---|---|

| CNC Operator | Load/unload parts, start cycles, basic monitoring | Safety, basic machine handling | No |

| CNC Programmer | Write G-code, CAM modeling, toolpath planning | CAD/CAM software, process knowledge | Usually not |

| Manual Machinist | Operate lathes/mills by hand | Tactile skill, experience | Yes |

| Process Engineer | Design machining strategy, select tools/machines | System design, cost analysis | Occasionally |

| CNC Machinist | Run, tweak, validate, troubleshoot, ensure quality | Hands-on mastery, problem-solving | Yes |

Sources: AMT Competency Model; China Machinery Industry Education Association (2023)

Key Insight: Programmers create the toolpaths. CNC machinists make them work in the real world. The best ones? They understand both — adjusting feeds, speeds, or fixtures on the fly to rescue a crashing program or improve surface finish.

Part 2: A Day in the Life — From Blueprint to Finished Part

Here’s what a typical workflow looks like for a CNC machinist in 2025:

1. Interpret Technical Documents

- Receive 2D drawings or 3D models (STEP, IGES, SolidWorks)

- Decode critical dimensions, GD&T (Geometric Dimensioning & Tolerancing), material specs (e.g., 7075-T6 aluminum, 316L stainless)

- Consult with engineering on setup strategy — spotting datum conflicts, tolerance stack-ups, or impossible features before metal is cut

Pro Tip: A great CNC machinist catches design flaws early — saving hours of rework and thousands in scrapped material.

2. Plan Setup & Workholding

- Choose fixtures: vises, chucks, vacuum plates, or custom jigs

- Establish datums without distorting thin-walled parts — may design multi-point clamping or stress-relief sequences

- Select cutting tools: carbide, ceramic, PCD — matched to material and operation

- Plan tool life management: preset replacement intervals, backup tools, wear tracking

3. Machine Setup & Calibration

- Load tools, set H (length) and D (radius) offsets

- Use edge finders or probes to set work coordinate systems (G54–G59)

- For high-precision jobs: perform multi-point calibration, thermal compensation, backlash tests

- Dry-run the program — check for toolpath interference, rotary axis limits, tool change collisions

4. First Article Inspection (FAI)

- Machine the first part. Measure with:

- Calipers (0.02mm resolution)

- Micrometers (0.01mm, ratchet stop technique)

- Dial indicators + height gauges

- CMM (Coordinate Measuring Machine) for complex GD&T

- Record measurements vs. drawing specs

- Perform measurement uncertainty analysis — feeding data into SPC (Statistical Process Control) charts

5. Optimize & Adjust Parameters

If dimensions are off or finish is poor, tweak:

- Spindle speed (S) → controls heat

- Feed rate (F) → affects finish

- Depth of cut (Ap) / Width of cut (Ae) → manages cutting force

Common Fixes: → Chatter? Reduce load, switch to uneven-flute tools, stiffen setup → Built-up edge? Optimize coolant, use chip-breaker geometry → Hole growing? Check tool wear, clamp slip, thermal drift — don’t guess, test systematically

6. Run Production & Monitor Quality

- Launch batch runs. Sample inspect (e.g., 1 in 10 pieces)

- Log production data: tool wear, alarms, dimensional trends

- Use material removal rate models to maximize throughput without sacrificing quality

- Monitor machine health — apply thermal management: internal coolant, high-pressure jets, intermittent cutting

7. Maintenance & 5S Discipline

- Daily checks: lubrication, coolant concentration, air pressure, spindle temp

- Chip cleanup, workspace organization (ISO 14001 compliant)

- Follow TPM (Total Productive Maintenance): log lubrication cycles, track wear parts

- Handle minor faults: alarm resets, stuck tool changes

- For recurring issues: launch RCA (Root Cause Analysis) + CAPA (Corrective Actions)

The CNC Machinist Skill Stack — Hard Skills, Soft Skills & Career Boosters

To thrive as a CNC machinist in 2025, you need a 3D skillset: technical mastery, professional habits, and advanced specialization.

HARD SKILLS — The 5 Pillars

1. Blueprint Reading & GD&T Fluency

Decode 2D drawings and 3D models. Understand ASME Y14.5 or ISO 1101 — MMC, RFS, datum reference frames.

Example: “⌀10H7 with position tolerance ⌀0.02 A|B|C” = hole must lie within 0.02mm cylinder defined by datums A, B, C.

2. G-Code Literacy & Debugging

Understand core codes: G00 (rapid), G01 (linear), G41 (tool comp), G54 (work offset), M03 (spindle on), M06 (tool change). Diagnose alarms — e.g., Fanuc ALM 438 = tool comp overtravel. Use macro variables (#100–#500) for parametric machining.

3. Precision Measurement Mastery

Operate calipers, micrometers, bore gauges, dial indicators, surface testers. Interpret CMM reports.

Example: Three micrometer readings on a 20mm shaft — 20.008, 20.010, 20.012 — signal ovality or measurement inconsistency. Track trends to predict tool wear.

4. Tool Selection & Cutting Optimization

Match tools to materials: → PCD for aluminum (mirror finishes) → Ceramics for hardened steel (high-speed) → Carbide for general purpose

Optimize material removal rate: → Roughing: high Ap, medium F → Finishing: low Ap, high F + high S

Coolant strategy: water-soluble for steel, oil-based for aluminum. For stainless/deep holes: pulsed coolant, peck cycles.

5. Troubleshooting & Problem Solving

Diagnose: chatter, drift, tool breakage, surface defects.

→ Chatter? Check frequency, reduce load → Drift? Check thermal growth, clamp force → Surface marks? Check spindle runout, bearing preload

SOFT SKILLS — The 4 Essentials

1. Obsessive Attention to Detail

±0.01mm = 1/7th a human hair. Top CNC machinists keep logs: size trends, tool changes, ambient conditions — traceable, defensible, data-driven.

2. Independent Problem Solving

No textbook answers. Example: Z-dimension off by 0.04mm on curved surface? Test tool length, fixture distortion, CAM offset, material stress — systematically.

3. Time Management & Multitasking

Juggle jobs, machines, setups. Use priority matrices. While waiting for CMM? Prep next setup. Maximize uptime.

4. Cross-Functional Communication

- Talk to programmers: suggest safer toolpaths

- Align with QC: agree on measurement points

- Feedback to engineering: share spindle load data

- Partner with maintenance: log alarm history, temp spikes

ADVANCED SKILLS — Career Accelerators

1. Multi-Axis Machining (4/5-Axis)

Master rotary tables, RTCP (Tool Center Point Control), avoid singularities. Critical for impellers, aerospace, medical implants.

2. CAM Software Basics

Use Fusion 360 or Mastercam to generate simple toolpaths. Adjust stepover, depth cuts, lead-in/out — balance speed vs. finish.

3. Preventive Maintenance Know-How

Scrape ways, preload ball screws, maintain spindles. Replace tool changers, encoders. Track MTBF (Mean Time Between Failures).

4. Industry Certifications

- NIMS CNC Turning/Milling Level 1 & 2 (USA)

- IHK Geprüfter CNC-Fachmann (Germany, requires B1 German)

- MOHRSS Senior/Technician Certificates (China)

- Fanuc β-Series / Siemens 840Dsl (Vendor-specific)

CNC Machinist Salary in China 2025 — Career Paths & Promotion Ladders

(Converted at ~7.2 RMB = 1 USD)

| EXPERIENCE LEVEL | MONTHLY SALARY (USD) | CORE COMPETENCIES | COMMON LOCATIONS |

|---|---|---|---|

| Junior (0–2 yrs) | $695 – $1,110 | Basic ops, blueprint reading, measuring | Yangtze Delta, Pearl River Delta |

| Mid-Level (3–5 yrs) | $1,110 – $1,670 | Independent setup, FAI, parameter tuning | Beijing-Tianjin, Chengdu-Chongqing |

| Senior (5+ yrs) | $1,670 – $2,500 | Complex parts, multi-axis, mentoring | Tier 1 & New Tier 1 cities |

| Expert / Specialist | $2,500 – $4,170+ | Aerospace/medical, 5-axis, process R&D | Shanghai, Shenzhen, Xi’an |

Notes:

- Entry-level: $695–$1,110/month

- Tier 1 cities: $835+/month (higher in foreign firms)

- Aerospace/medical: 1.5–2x local rates

- Senior techs: $27,800+/year

Career Progression Paths for CNC Machinists

1. Technical Track (Depth)

Operator → CNC Machinist → Senior Setup Tech → CNC Programmer → Process Engineer → Manufacturing Tech Manager

(Progression: Single machine → Multi-machine sync → Process standardization → Smart line design)

2. Management Track (Breadth)

Team Lead → Production Supervisor → Workshop Manager → Operations Director → Plant Manager

(Scope: Staff scheduling → Cost control → KPI delivery → Strategy execution)

3. Specialist Track (Niche Mastery)

5-Axis Specialist → Medical Device Certifier → Aerospace Structural Machinist → Smart Manufacturing Integrator

(Certifications: AS9100 aerospace, ISO 13485 medical, Industry 4.0 frameworks)

Career Outlook: Is CNC Machining a Good Career in 2025?

Short answer: Heck yes.

- High technical barrier → low competition from unskilled labor

- Experience compounds value → you get more valuable every year

- Demand is rock-solid — especially in aerospace, medical, EVs

- China’s Ministry of HR (2024): 12% annual talent gap → officially “high-demand occupation”

- Employers care about what you can fix, not what degree you hold

Master 5-axis, medical compliance, or aerospace standards, and you command 30%+ salary premiums.

How to Become a CNC Machinist — Training, Certifications & Apprenticeships

3 Main Entry Paths

1. Vocational School Route

- Duration: 3 years (secondary or college level)

- Curriculum: Blueprint reading, GD&T, CNC programming, CAM, machine labs

- Pros: Structured, industry partnerships, job placement

- Bonus: Many now include smart manufacturing, robotics, digital twin labs

2. Private Training Programs

- Duration: 3–6 months full-time (200+ hours on real machines)

- Choose wisely: Look for industrial-grade equipment, job placement, recognized certs

- Recommended: China Mechanical Engineering Society, MOHRSS-approved institutes

- Highlights: Real production orders, tool management drills, SPC data exercises

3. Apprenticeship Path

- Journey: Operator → Apprentice → Machinist (2–3 years)

- Keys: Find a good mentor, stay curious, document everything

- Build your portfolio: Troubleshooting logs, first-article reports, process improvement proposals

CNC Machinist FAQs — Answering “Is CNC Machining a Good Career?” and Other Top Questions

1: Will CNC machinists be replaced by automation?

No — but the role will evolve. Robots handle repetition. Humans handle first-offs, optimization, troubleshooting, and maintenance. You’re becoming a human-machine collaboration expert — more technical, not less.

2: Can I learn this without an engineering background?

Absolutely. Basic middle-school math is enough. Success hinges on spatial reasoning, patience, and responsibility. Many top CNC machinists started in humanities — became experts through 2–3 years of shop-floor grit.

3: Is the job physically demanding? Shift work?

Moderate intensity. Shifts are common. Expect 6–8 hours standing. Lifting under 20kg. 80% of shops run 2 or 3 shifts — night shifts pay extra. Some precision shops (medical, aerospace) stick to standard hours.

4: Is this a good career for women?

Excellent fit. Precision manufacturing rewards attention to detail and logical thinking — not brute strength. Germany, Japan, and China all have thriving female CNC machinists in medical, watchmaking, and aerospace sectors.

5: Is CNC machining a good long-term career?

Yes — it’s a “gold-rush” trade. Your value grows with experience. You’re not chasing trends — you’re building the backbone of industry. Stable, respected, and increasingly scarce.

6: Is there high demand for CNC machinists in 2025?

Sky-high and rising. Especially in aerospace, medical, and EV sectors. China’s Ministry of HR reports 12% annual growth in CNC talent gaps. Employers care about what you can fix, not what degree you hold.

Final Word: Become a CNC Machinist in 2025 — And Build the Future

Behind the question “What is a CNC machinist?” lies a deeper truth: modern manufacturing is redefining what it means to be a skilled technician.

CNC machinists aren’t assembly-line cogs. They’re process engineers, quality guardians, and efficiency hackers — turning pixels into precision, code into components, chaos into controlled production.

They defend ±0.01mm with calipers. They debug G-code like detectives. They rescue jobs from the brink of failure.

Paths are clear: → Go deep as a 5-axis guru → Go wide as a production manager → Go niche in medical or aerospace

Salaries rise with skill — and in high-barrier industries, you’re golden.

Looking for technical mastery, stable income, and tangible pride in your work?

Then yes — CNC machining is not just a good career. It’s one of the smartest bets you can make in the age of Industry 4.0.

Demand? Only growing. Scarcity? Guaranteed for the next decade.