What Is a CNC Grinder

A CNC grinder is a cornerstone of modern manufacturing, harnessing computer numerical control (CNC) technology to spin a grinding wheel at blazing speeds, delivering ultra-smooth surfaces on materials like metal, ceramics, or tough plastics with pinpoint, micron-level precision. Think of it as a digital craftsman, sculpting flawless finishes for critical components in industries like aerospace, automotive, and medical devices. In U.S. factories, CNC grinding machines turn “good enough” into perfection, making them a must-have for high-precision grinding in demanding production environments.

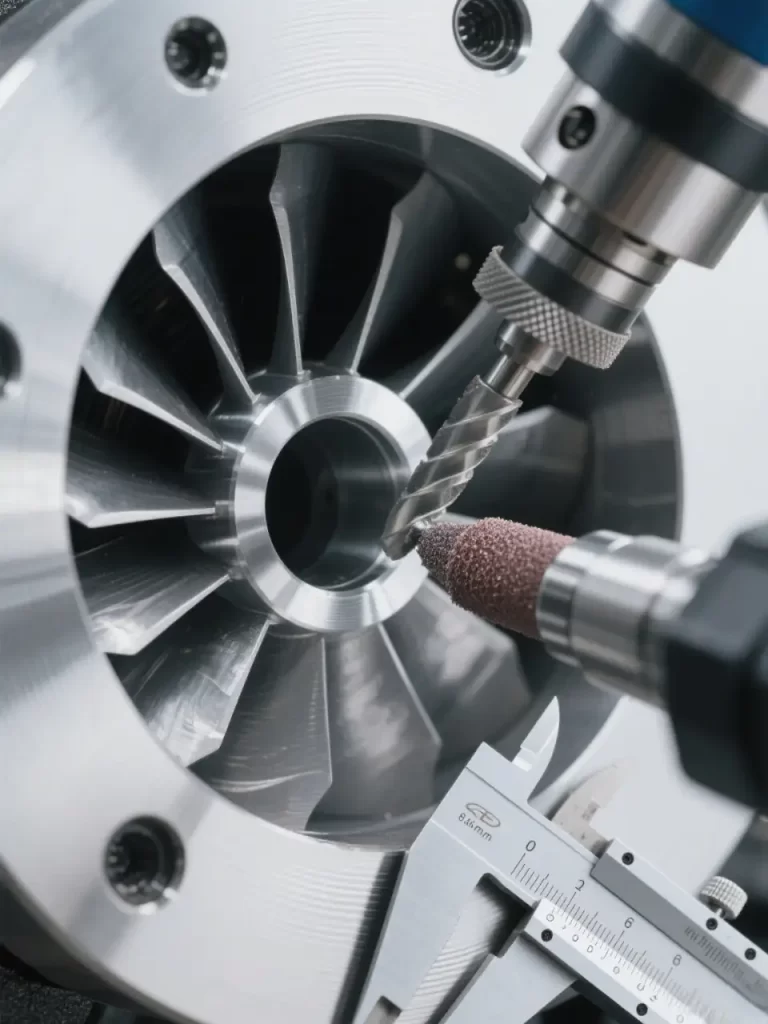

The Core Concept of CNC Grinders

At its heart, a CNC grinder uses computer programming to achieve precision surface finishing on hard materials. Specifically, the grinding wheel spins rapidly, shaving off tiny layers to create smooth, accurate surfaces. In other words, it’s like a master artisan following precise digital blueprints to craft impeccable parts. For example, American manufacturers rely on CNC precision grinders to meet the rigorous quality standards of aerospace and automotive industries.

Unlike old-school grinders, which leaned on an operator’s instincts—tweaking the wheel and guessing speeds—manual methods were slow and inconsistent. By contrast, how CNC grinders work transforms the game. With precise code, these machines tackle complex tasks with errors so small they’re practically invisible. Moreover, this high-precision grinding technology is critical for parts like jet engine turbine blades, where perfection is non-negotiable.

The magic of CNC lies in automation and control. The CNC system, the machine’s “brain,” uses algorithms to guide the grinding wheel with surgical accuracy. Whether it’s a CNC cylindrical grinder shaping round components or a CNC surface grinder flattening bases, the system ensures seamless coordination in 3D space. As a result, automation slashes human error, keeps the machine running 24/7, and ramps up productivity for intricate parts like medical implants.

Components of a CNC Grinder

To get the full picture of a CNC grinding machine, you need to know its key parts. Essentially, it’s a high-tech puzzle where every piece—hardware, software, and support systems—plays a vital role. By breaking down these components, you’ll see how they team up to deliver precision grinding equipment for U.S. manufacturing.

Core Hardware

The hardware is the machine’s backbone. First off, the machine bed, often cast iron, acts as a rock-solid “skeleton,” keeping things steady during high-speed grinding. Next up, the spindle serves as the “heart,” powering the grinding wheel’s spin. Its speed and balance directly affect grinding accuracy. Then there’s the grinding wheel itself—the star of the show—cutting and smoothing with shapes and materials tailored to the job, like cylindrical grinder wheels for specific tasks. Finally, the control panel is the “command hub,” where operators input instructions and keep tabs on CNC grinder operations.

Software and CNC Control

The software is the CNC grinder’s brain, just as crucial. Specifically, the CNC system runs pre-programmed instructions, often using G-code or specialized software. For instance, grinding an aerospace part might require hundreds of code lines to map out complex curves. What’s more, top-notch software boosts efficiency and catches errors early. In U.S. shops, operators spend serious time mastering CNC grinder programming to ensure flawless results, as quality depends on spot-on code.

Support Systems

Support systems are the unsung heroes. Take the cooling system—it’s like a “firefighter,” spraying coolant to keep the wheel and workpiece from overheating, preventing warpage and extending wheel life. Likewise, fixturing locks the workpiece in place, ensuring zero wiggle for precision component grinding. Optional add-ons like filtration or auto-tool changers make operations smoother, keeping the machine running like a dream in busy American factories.

How a CNC Grinder Works

Grasping how a CNC grinder works unveils its brilliance. Far from a basic tool, it’s a blend of computer precision and mechanical muscle, churning out parts with unmatched accuracy and finish. Let’s dive into the grinding process, the role of CNC programming, and the secrets behind its precision and surface quality.

The Grinding Process

The grinding process boils down to the grinding wheel meeting the workpiece. Specifically, the wheel spins at high speeds, shaving off microscopic material layers. The workpiece—be it metal, ceramic, or plastic—takes shape gradually, often in setups like a CNC cylindrical grinder for round parts. Each pass removes just a few microns, sculpting with finesse. Meanwhile, coolant sprays keep temperatures in check, preventing damage to the wheel or workpiece. Without it, friction could derail the precision grinding process.

The Role of CNC Programming

CNC grinder programming is the operation’s backbone. In particular, G-code or specialized software dictates the wheel’s path and the workpiece’s position. For complex parts like turbine blades, hundreds of code lines choreograph multi-axis movements. Plus, factors like speed, feed rates, and wheel wear need precise coding. A single mistake can scrap a part, so U.S. operators pour hours into perfecting G-code programming to nail every detail.

Precision and Surface Quality

What makes CNC grinders stand out is their grinding accuracy and surface quality. Thanks to the CNC system’s tight control and the machine’s sturdy build, errors stay within microns—thinner than a hair. Additionally, a rigid machine bed and stable spindle wipe out vibrations, ensuring consistency. As a result, finished parts gleam with mirror-like surfaces, with roughness (Ra) as low as 0.1 microns—crucial for automotive engine grinding or medical device grinding.

Types of CNC Grinders

CNC grinder types come in various flavors, each built for specific tasks. Like tools in a toolbox, picking the right one ensures efficiency in U.S. shops. Let’s explore CNC cylindrical grinders, CNC internal grinders, CNC surface grinders, centerless grinders, and specialty grinders, along with their unique strengths.

CNC Cylindrical Grinder

A CNC cylindrical grinder shines at shaping round parts like shafts or piston pins. The workpiece spins between a chuck or centers, while the grinding wheel smooths the outer surface to exact specs. For example, U.S. auto shops use these for engine crankshaft grinding, where tolerances are razor-tight. Thanks to CNC control, complex profiles are a snap, leaving manual grinders in the dust.

CNC Internal Grinder

CNC internal grinders focus on the inside of holes, like bearing housings or hydraulic cylinders. Their smaller wheels slip inside to create smooth, precise inner surfaces. Moreover, CNC systems handle tapered or multi-step holes with ease. In American aerospace, these machines ensure turbine part bore grinding meets strict standards.

CNC Surface Grinder

CNC surface grinders are wizards at flat surfaces, delivering mirror-smooth finishes with jaw-dropping tolerances. The wheel moves over a magnetically secured workpiece, ideal for mold base grinding or machine components. As a result, U.S. mold shops lean on CNC surface grinders for intricate flat patterns, making them a workshop staple.

Centerless Grinder

CNC centerless grinders are one-of-a-kind, needing no clamping. A grinding wheel and regulating wheel team up to shape small parts like needles or rollers at lightning speed. This makes them perfect for high-volume component grinding in U.S. medical and automotive industries, keeping quality tight across big batches.

Specialty Grinders

Specialty CNC grinders, like tool grinders, tackle niche jobs such as sharpening drills or milling cutters, keeping tools razor-sharp and extending their life. Similarly, thread grinders or gear grinders handle specific components with precision. In U.S. aerospace, these machines ensure tool grinding and parts meet exacting standards.

Applications of CNC Grinders

CNC grinder applications span U.S. manufacturing, excelling wherever precision and smooth surfaces matter. From aerospace to medical devices, they’re the backbone of top-tier production. Let’s check out their key uses.

Aerospace Industry

In aerospace, CNC grinders craft components like turbine blades and landing gear parts. Micron-level tolerances and mirror-grade finishes are a must. For instance, CNC cylindrical grinders and internal grinders shape tough alloys with precision, ensuring reliability under extreme conditions. U.S. giants like Boeing rely on aerospace component grinding for flawless parts.

Automotive Sector

The automotive industry depends on CNC grinders for engine and drivetrain components. Crankshafts, camshafts, and gears need spot-on dimensions and smooth surfaces to boost efficiency. CNC surface grinders polish cylinder blocks, while centerless grinders churn out piston pins in bulk. Consequently, U.S. manufacturers like Ford use automotive component grinding to keep vehicles running smoothly and efficiently.

Medical Device Manufacturing

Medical devices demand unmatched precision, and CNC grinders deliver. Orthopedic implants, surgical blades, and dental tools require frictionless surfaces and exact shapes. Internal grinders perfect implant bores, while cylindrical grinders handle outer contours. In the U.S., medical device grinding meets strict standards, ensuring patient safety.

Mold Making and General Machinery

In mold making grinding, CNC surface grinders create flat, durable molds for plastic or metal parts. Likewise, general machinery like pumps or hydraulic components benefits from CNC grinders tackling complex shapes. Smaller U.S. shops use general machinery grinding to meet diverse client needs, balancing speed and precision.

Advantages of CNC Grinders

CNC grinders are game-changers in U.S. manufacturing, offering unbeatable perks over traditional methods. From precision to speed, they redefine efficiency. Here’s why they rule.

Unmatched Precision and Consistency

First, CNC grinders deliver grinding accuracy down to microns, ensuring identical parts every time. Whether it’s a cylindrical grinder or surface grinder, the CNC system wipes out errors, making it ideal for aerospace and medical applications. U.S. shops meet tough quality standards with ease thanks to this consistency.

Versatile and Flexible

Plus, CNC grinders handle complex shapes like a pro. From curved turbine blades to tapered holes, CNC grinder programming enables multi-axis flexibility. As a result, American manufacturers tackle diverse client specs without breaking a sweat.

High-Speed Production

What’s more, CNC grinders supercharge production speed. Unlike manual grinders, they run non-stop, with centerless grinders excelling at high-volume tasks. In the U.S., where time is money, this efficiency drives profits.

Reduced Human Intervention

Finally, automation cuts down on operator involvement. The CNC system monitors and tweaks, reducing errors and simplifying training. With skilled labor hard to come by in U.S. shops, this ease of use is a major win.

Limitations of CNC Grinders

Despite their strengths, CNC grinders aren’t perfect. Knowing their downsides helps shops plan smarter. Let’s dive into the main limitations.

High Initial and Maintenance Costs

First off, CNC grinder costs are steep, often hitting six figures. Add coolant systems, fixturing, and software, and the price skyrockets. CNC grinder maintenance isn’t cheap either—wheel replacements and tune-ups hit hard. For small U.S. shops, these costs can be a tough pill to swallow.

Skilled Operation and Maintenance

Also, CNC grinder operation and upkeep demand expertise. Fixing issues like spindle glitches or wheel wear calls for seasoned pros. In the U.S., high labor costs and training time pose hurdles for smaller outfits.

Dependence on Programming

Lastly, CNC grinders lean heavily on G-code programming. A coding error can ruin parts, and programming complex components takes time. Without skilled coders, U.S. shops risk delays and costly CNC grinder programming errors.