What Can CNC Machines Do? Uses and Benefits in 2025

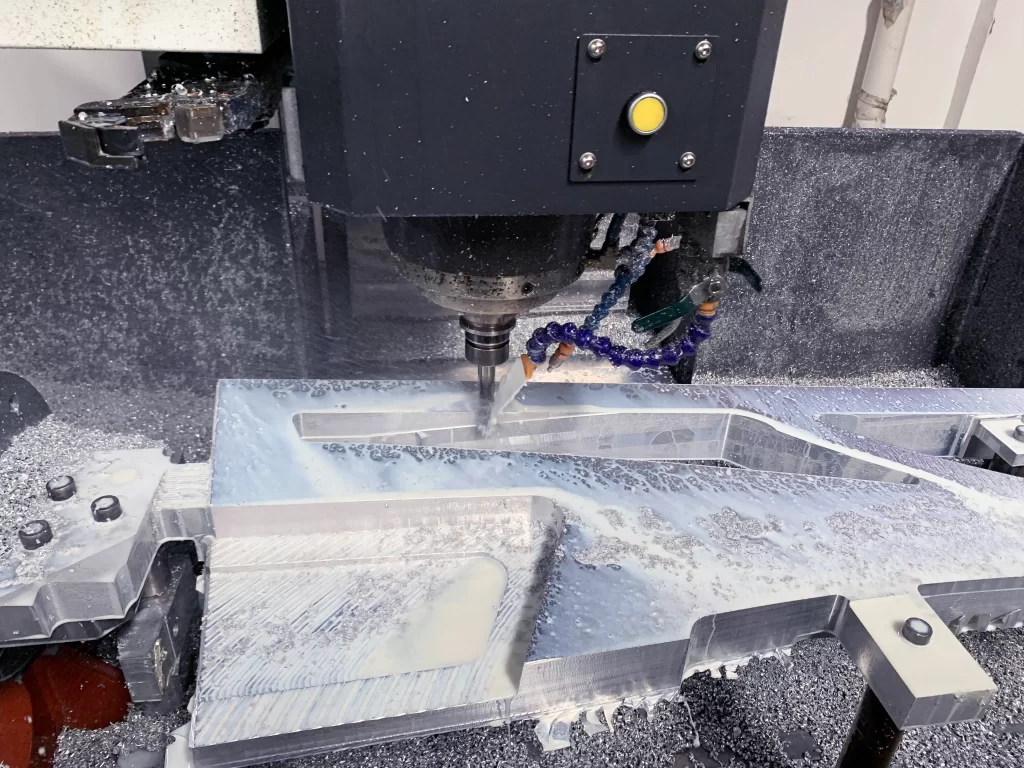

Computer Numerical Control (CNC) machines are transforming modern manufacturing with their precision and versatility. These computer-driven systems, powered by advanced CAD/CAM software, masterfully cut, engrave, and shape materials like metal, wood, plastic, and composites using optimized toolpaths and multi-axis operations. From crafting intricate industrial components to sculpting artistic masterpieces, CNC machines unlock endless possibilities with tolerances as tight as ±0.005 inches (0.13 mm).

Whether you’re a beginner looking for affordable CNC machines or a small business owner seeking the best CNC machines for your needs, these tools deliver. High-powered models like the CNC Gantry Milling Machine, boasting spindle speeds up to 24,000 RPM, excel in large-scale production, while compact versions suit DIY enthusiasts. With micron-level precision and automated efficiency, CNC fabrication drives industries like automotive, aerospace, furniture, and jewelry. The global CNC machine market is expected to hit $101.22 billion in 2025, growing at a 9.9% CAGR through 2032, fueled by demand for high-precision manufacturing.

What Is a CNC Machine?

Understanding CNC Technology

A CNC machine uses G-code programming to guide cutting tools with pinpoint accuracy, achieving errors as low as microns (1 mm = 1,000 microns) through precise feed rates and spindle dynamics. These systems efficiently handle milling, turning, and routing, often equipped with automatic tool changers (ATC) for seamless workflows. For example, a CNC Vertical Machining Center produces complex prototypes with multi-axis precision, while CNC repair services keep equipment running smoothly with minimal downtime. As a backbone of modern manufacturing, CNC machines reduce human error, making them perfect for both high-volume production and custom projects, with advanced setups offering positional accuracy up to ±0.0001 inches.

Types of CNC Machines

CNC machines come in various forms, each tailored for specific tasks with unique axis configurations:

- CNC Milling Machines: These versatile tools process metals, wood, and plastics, with models like the CNC Gantry Machining Center mastering large, complex 3D shapes through 5-axis interpolation.

- CNC Lathes: Ideal for crafting cylindrical parts like bolts and shafts, often with live tooling for added flexibility. The mini CNC lathe is compact and user-friendly, making it one of the best CNC machines for beginners.

- CNC Routers: Designed for engraving and cutting softer materials like wood and plastic, woodworking CNC router machines shine in furniture and signage production, offering affordable solutions for small businesses with high-speed engraving capabilities.

- Plasma Cutting Machines: These use thermal ionization to slice through metal sheets quickly, often paired with CNC grinding machines for smooth, burr-free finishes.

Specialized tools, like the Aluminum Profile CNC Machine, focus on lightweight metals for electronics and construction, using vacuum fixturing for stability.

Materials Used in CNC Machining

CNC machines handle a wide range of materials with tailored settings. Wood is shaped through CNC wood routing for intricate furniture designs, with feed rates adjusted to avoid tear-out. Metals like aluminum and steel are machined for durable components, with the Aluminum Profile CNC Machine using coolant systems to manage thermal expansion for precise cuts. Plastics are perfect for prototypes and casings, supported by CNC machine parts like ball screws for smooth, backlash-free motion. Composites, prized in aerospace for their strength-to-weight ratio, require diamond-coated tools to combat abrasion, while foam is cost-effective for signage and easily shaped by CNC routers. CNC machines for prototyping enable rapid iteration with minimal waste, achieving tolerances as fine as ±0.001 inches for critical features.

Applications of CNC Machines

Industrial Manufacturing

- Automotive: CNC Profile Machining Centers produce engine blocks and gears with tolerances of ±0.002 inches.

- Aerospace: Turbine blades and structural panels rely on CNC grinding machines for finishes with surface roughness (Ra) below 0.8 microns.

- Electronics: Miniaturized CNC tools create circuit board housings and device stands with high repeatability.

Woodworking and Furniture Design

Woodworking CNC router machines craft custom tables, chairs, and cabinets, using nested toolpaths to maximize material efficiency. CNC wood routing adds intricate details to signs and headboards, while CNC milling machines shape architectural features like dovetail joints with precision.

Metal Processing

- Jewelry: Rings and pendants are polished to a mirror finish using burnishing tools, often with micro-machining techniques.

- Tools: CNC Vertical Machining Centers produce durable molds and knife blades with hardened inserts.

- Nameplates: Metal logos and badges are etched with laser-integrated precision.

Art and Sculpture

CNC Gantry Milling Machines carve 3D reliefs and murals in wood or metal using adaptive roughing strategies. Plasma cutters shape metal art installations with minimal heat-affected zones.

Prototyping and Product Development

CNC machines for prototyping create smart device casings and medical components, cutting time-to-market by 40-60% compared to manual methods. CNC repair services ensure consistent equipment performance.

Signage and Advertising

CNC routers produce acrylic signs with beveled edges, while foam letters for billboards are shaped cost-effectively. The Aluminum Profile CNC Machine crafts durable metal shop signs built to withstand the elements.

Home DIY and Creative Projects

Mini CNC lathes make coasters and photo frames with threading capabilities. Entry-level CNC routers enable wall art and storage boxes, bringing professional-grade crafting to hobbyists. For those wondering how to choose CNC machines, affordable models with intuitive interfaces are ideal for beginners.

Four Key Benefits of CNC Machines

Unmatched Precision and Consistency

CNC systems deliver micron-level accuracy, with CNC Vertical Machining Centers ensuring uniform results that meet aerospace ISO 2768 standards.

Versatile Across Materials and Industries

From aluminum machining to wood carving, CNC machines adapt to any sector, supported by components like linear guides for smooth operation.

Automation for Cost Efficiency

CNC machines enable 24/7 production, slashing labor costs by up to 70% in high-volume settings. Free CNC software streamlines programming, and while CNC machines cost varies, affordable options make them accessible for small businesses. Industry data shows CNC adoption can boost productivity by 50-300%, with the CNC tool market growing at 7.2% annually.

Simplifying Complex Designs

G-code and parametric programming enable intricate curves and molds, reducing cycle times and turning challenging designs into reality effortlessly.

CNC Machine Maintenance and Selection Tips

Regular CNC repair and maintenance—such as cleaning and lubricating components—prevent spindle wear and extend machine life. When deciding how to choose CNC machines, consider factors like size, power, and ease of use. The best CNC machines for small businesses balance scalability and affordability. Industry reports highlight a 50% productivity boost from CNC adoption, with AI-driven toolpath optimization emerging as a trend for 2025.

Why Choose Us?

Our company provides precise and efficient solutions for businesses, designers and enthusiasts. Whether you’re crafting furniture with a woodworking CNC router machine, prototyping with a CNC Gantry Machining Center, or personalizing projects with a mini CNC lathe, our equipment delivers. We provide professional training, custom setups, free CNC software integration, and CNC repair guidance to ensure a seamless experience.