Top 6 Essential Machine Shop Tools Manufacturing Workshop Needs

In today’s manufacturing landscape, CNC machining dominates global production output at 61%, far outpacing fabrication (22%) and welding (17%). But simply owning CNC machines isn’t enough. True competitive advantage comes from strategically equipping your workshop with the right combination of core tools, optimized parameters, and smart integration. This guide details the six indispensable machine shop tools—enhanced with actionable technical insights from Deli-CNC’s engineering practice—to transform your operation from functional to future-ready.

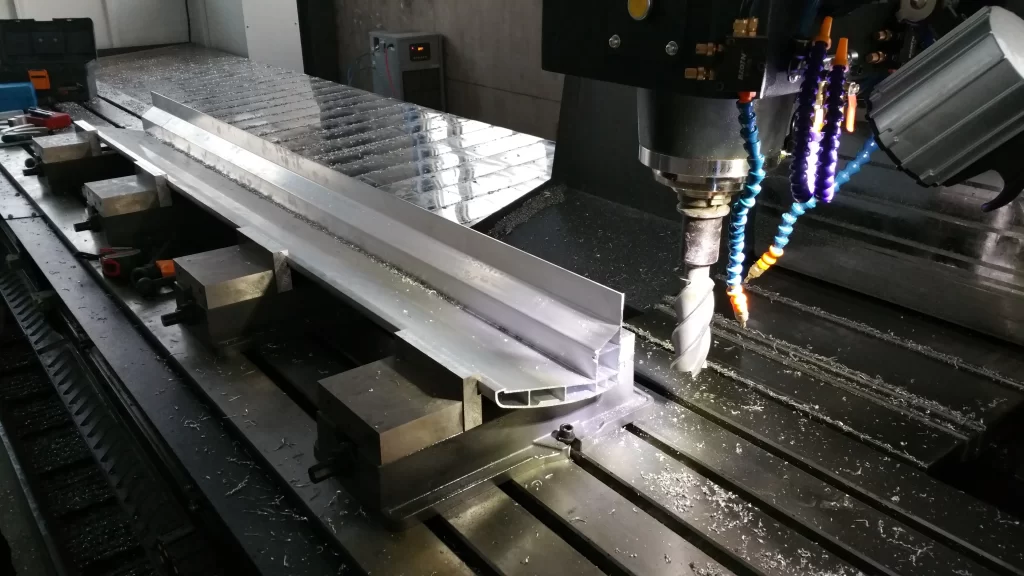

1. CNC Milling Machine: The Precision Powerhouse

CNC milling machines are central to modern workshops, but their true potential is unlocked through parameter optimization and tooling intelligence.

Core Functions, Enhanced

Cutting with Intelligence

Use pre-programmed G-code to cut metals, plastics, and composites—but go beyond basic paths. Implement:

- Climb milling to reduce tool wear.

- Helical interpolation for deep holes, distributing cutting forces evenly.

- Adaptive clearing strategies to maintain constant chip load, boosting efficiency by 10–20%.

Shaping Complex Geometries

From aerospace impellers to medical implants, 3D contours demand specialized tools:

- Ball nose end mills: For finishing, keep stepover ≤ 0.2 mm to achieve Ra ≤ 0.8 μm.

- Flat end mills: Use high-feed strategies (ap = 0.3–0.5 mm, fz ≥ 1.2 mm/tooth) for rapid 2D contouring.

Performance Optimization: The Deli-CNC Framework

| PARAMETER | ALUMINUM ALLOY | STEEL | TITANIUM ALLOY |

|---|---|---|---|

| Cutting Speed (Vc) | 200–400 m/min (optimal: 300) | 50–150 m/min | 20–60 m/min |

| Feed per Tooth (fz) | Rough: 0.1–0.3 mm/tooth Finish: 0.05–0.15 mm/tooth | Same as Al, but lower Vc | Shallow multi-pass, fz < 0.1 |

| Depth of Cut (ap) | Rough: 1–2× tool dia. Finish: 0.1–0.5 mm | Same | ap ≤ 0.5 mm per pass |

Real-World Win: An aerospace shop reduced Vc from 50 to 30 m/min on Inconel, extending tool life by 40% and cutting total machining time by 15%.

Tooling & Integration Essentials

- Coatings Matter:

- TiAlN (purple-black): Heat-resistant for stainless steel (+30% tool life).

- DLC (glossy black): Prevents aluminum adhesion.

- Tool Holders: Use HSK for 5-axis high-speed work; BT for general-purpose.

- Pre-Set & Compensate: Measure tools with a presetter (±0.02 mm accuracy) and input offsets into D-codes.

- TLM Systems: Track tool usage via RFID or cycle count to prevent unplanned downtime.

2. Lathe: The Master of Symmetry

Lathes remain irreplaceable for producing shafts, pulleys, gears, and fasteners with perfect rotational symmetry.

Key Capabilities

Turning

Achieve precise diameters and smooth finishes (Ra ≤ 1.6 μm) by matching parameters to material:

- Stainless steel: Vc = 20–50 m/min, fz = 0.05–0.15 mm/tooth.

- Cast iron: Vc = 80–150 m/min.

Threading

Move beyond taps. Thread mills offer superior flexibility:

- Machine multiple diameters with one tool.

- Ideal for M12+ threads in stainless steel or titanium.

- No chip evacuation issues in blind holes.

Why CNC Lathes Win

- Consistency: Produce identical parts across thousands of cycles.

- Flexibility: Switch programs in minutes for custom batches (e.g., medical implants).

- Integration: Pair with robotic arms for lights-out production.

Pro Tip: Use IoT-enabled CNC lathes for predictive maintenance—reducing unplanned stoppages by up to 40%.

3. Drill Press: The Foundation of Accurate Assembly

While CNC machines can drill, a dedicated drill press ensures repeatability and safety for high-volume hole patterns.

Multi-Function Versatility

| OPERATION | PURPOSE |

|---|---|

| Drilling | Primary hole creation |

| Reaming | Finish to IT7 tolerance |

| Countersinking | Flush screw heads |

| Counterboring | Clearance for bolt heads |

| Tapping | Internal threads |

Optimization Tips

- Always center-drill first to prevent drill wander (>0.1 mm error risk).

- For deep holes, use peck drilling (G83) with internal-coolant drills.

- Table adjustability and laser guides enhance precision for complex layouts.

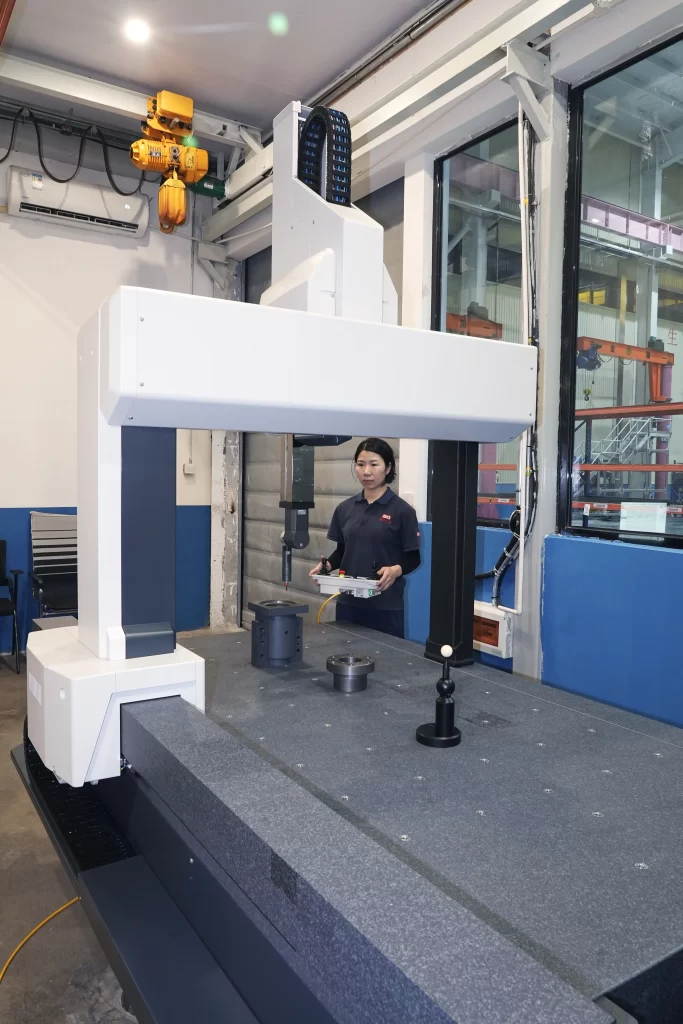

4. Measurement Tools: The Eyes of Quality Control

Precision without verification is guesswork. A layered measurement strategy is non-negotiable in aerospace, automotive, and medical manufacturing.

The Four-Tier Measurement System

- Shop-Floor Quick Checks

- Digital calipers: OD/ID, depth, step (±0.01 mm).

- Micrometers: Sub-0.001 mm accuracy for critical features.

- Setup & Alignment

- Edge finders: Locate part zero within ±0.005 mm.

- Machinist’s squares: Verify 90° alignment.

- In-Process Control

- Dial/digital indicators: Check runout, flatness.

- In-machine probes (e.g., Deli Probe): Auto-measure → compensate → close the loop.

- Final Validation

- CMM (Coordinate Measuring Machine): Full GD&T compliance.

- Profilometers: Verify surface roughness (target: Ra ≤ 1.6 μm for finishes).

Critical Practice: If Ra exceeds 1.6 μm, reduce feed rate or replace the tool—don’t ship compromised parts.

5. Deburring Tools: Safety, Quality, and Automation

Burrs compromise safety, assembly, and fatigue life. Modern deburring is programmed, not manual.

Smart Deburring Strategies

| BURR TYPE | SOLUTION | INTEGRATION |

|---|---|---|

| Edge burrs | Chamfering tools | Add G01 chamfer at end of CNC program |

| Internal burrs | Deburring drills | Combine with drilling cycle |

| Complex contours | Brush or vibratory systems | Post-machine automation cell |

Industry Shift: Aerospace and EV battery tray manufacturers now mandate automated deburring to ensure worker safety and part reliability.

6. Integrated Smart Systems: From Tools to Intelligence

The future isn’t just about better tools—it’s about connected systems.

Three Pillars of Integration

- Adaptive Control Systems (ACS)

- Sensors monitor cutting force, vibration, and temperature.

- ACS auto-adjusts Vc/F in real time (e.g., lowers feed on hard spots in cast iron).

- Result: 30% longer tool life in turbine blade machining.

- Robotics & Automation

- Robotic arms handle loading, inspection, and packaging.

- Automated vises and CNC door control streamline workflows.

- Data-Driven Continuous Improvement

- Build a parameter database: Log material, tool, Vc, F, ap, tool life.

- Review quarterly: One shop cut tool changes by 20% and boosted efficiency by 15% through data analysis.

Frequently Asked Questions (FAQ)

Q1: What are the six most essential machine shop tools for a modern manufacturing workshop?

A: Based on Deli-CNC’s engineering practice, the core six are:

- CNC Milling Machine – for complex contouring and high-speed machining

- Lathe – for precision cylindrical and symmetrical parts

- Drill Press – for accurate, repeatable hole placement (±0.001″)

- Measurement Tools – including calipers, micrometers, CMMs, and in-machine probes to ensure Ra ≤ 1.6 μm surface finish

- Deburring Tools – automated chamfering cutters or brush systems for edge finishing

- Smart Integration Systems – featuring TLM (Tool Life Management), ACS (Adaptive Control), and robotic automation

Together, they form a closed-loop system: machine → measure → refine → automate.

Q2: How do I select the right cutting parameters for stainless steel?

A: Stainless steel requires conservative settings due to its toughness and poor thermal conductivity:

- Cutting Speed (Vc): 20–50 m/min

- Feed per Tooth (fz): 0.05–0.15 mm/tooth (0.1 mm/tooth recommended to reduce chipping)

- Depth of Cut (ap): ≤ 0.5 mm for finishing

- Tool Coating: TiAlN (purple-black) extends tool life by up to 30%

- Coolant: Use high-pressure emulsion for heat control

Never use high Vc—this causes work hardening and rapid tool wear.

Q3: What should I do if surface roughness exceeds Ra 1.6 μm?

A: Ra > 1.6 μm indicates finishing quality failure. Take these steps:

- Reduce feed rate (F) – e.g., from 0.2 to 0.1 mm/rev

- Decrease stepover – for ball nose end mills, keep stepover ≤ 0.2 mm

- Replace worn tools – dull edges increase roughness

- Check machine vibration – loose spindles or fixtures cause chatter marks

In aerospace applications, parts with Ra > 1.6 μm must be reworked or scrapped.

Q4: Can a CNC milling machine replace a drill press?

A: Yes, but with trade-offs:

- Advantages: CNC mills offer multi-axis positioning, helical interpolation for deep holes, and automated hole patterns.

- Limitations: Frequent small-tool changes reduce efficiency; G83 peck drilling is needed for deep holes to avoid chip clogging.

- Best Practice: Use a dedicated drill press for high-volume simple holes, and reserve the CNC mill for complex or precision hole systems.

70% of Deli-CNC customers use both—each for its optimal role.

Q5: How can I achieve lights-out (unmanned) production?

A: Three pillars are required:

- Hardware: Robotic part loading/unloading + automated vises + CNC door control

- Software:

- TLM System: Tracks tool usage via RFID or cycle count to prevent unexpected breakage

- ACS (Adaptive Control): Adjusts feed/speed in real time based on cutting force

- Process Integration: Embed deburring, in-machine probing, and compensation at the end of the CNC program

One EV battery tray manufacturer achieved 16 hours of continuous operation with 80% less manual intervention.

Q6: How should a beginner start optimizing CNC parameters?

A: Follow this 3-step method:

- Start with baselines:

- Aluminum: Vc = 300 m/min, F = 0.2 mm/rev

- Stainless steel: Vc = 30 m/min, fz = 0.1 mm/tooth

- Run small-batch tests: Measure tool wear, surface finish (Ra), and cycle time

- Build a parameter database: Log material, tool type, Vc/F/ap, and outcomes. Review quarterly.

One shop reduced tool changes by 20% and boosted efficiency by 15% through data-driven tuning.

Conclusion: Build a System, Not Just a Shop

Equipping your workshop with these six tools—CNC mill, lathe, drill press, measurement suite, deburring system, and smart integration layer—creates a foundation for sustainable excellence. But remember: the machine is only as good as its parameters, its tools, and its data.

Start with manufacturer-recommended settings, then test, measure, and optimize. Leverage CAM simulation, in-machine probing, and TLM systems. Partner with suppliers like Deli-CNC who provide not just machines, but end-to-end process expertise.

In modern manufacturing, the goal isn’t just to make parts—it’s to make them faster, smarter, and with zero compromise on quality. With the right tools and the right strategy, your workshop can lead the next industrial revolution.ce.