Quality Inspection for High-Precision CNC Machining: Tools and Techniques Explored

High-precision CNC machining is a cornerstone of modern manufacturing, delivering micron-level accuracy to meet the stringent demands of industries like aerospace, medical devices, and automotive. However, achieving such precision is challenging, and robust quality inspection is essential to ensure parts meet design specifications. This article examines high-precision CNC machining quality inspection through six key aspects: core requirements, common tools, inspection techniques, implementation strategies, industry applications, and challenges with solutions, offering practical insights for CNC machining solutions.

1. Core Inspection Requirements

1.1 Tolerance Control

- Definition: The acceptable deviation between designed and actual dimensions.

- Requirement: High-precision CNC machining demands tolerances as tight as ±0.001 mm.

- Challenges: Thermal distortion, tool wear, and machine stability.

- Solution: Real-time monitoring with Coordinate Measuring Machines (CMMs) and high-precision CNC machining equipment ensures consistent accuracy.

1.2 Surface Finish

- Key Metric: Ra (average roughness), typically ≤0.1 μm.

- Impact: Influences friction, sealing performance, and biocompatibility.

- Tools: Surface roughness testers and microscopes.

- Optimization: Stabilize machining parameters and replace tools regularly, leveraging CNC machining technology for superior surface quality.

1.3 Dimensional Consistency

- Goal: Maintain uniformity in high-volume production.

- Methods: Statistical Process Control (SPC), optical comparators, and laser scanners, ideal for automotive manufacturing CNC machines.

1.4 Material Imperfections

- Risks: Micro-cracks, porosity, or voids compromising quality.

- Techniques: Ultrasonic testing, X-ray inspection, and fluorescent penetrant testing, widely used in aerospace precision machining.

2. Common Inspection Tools

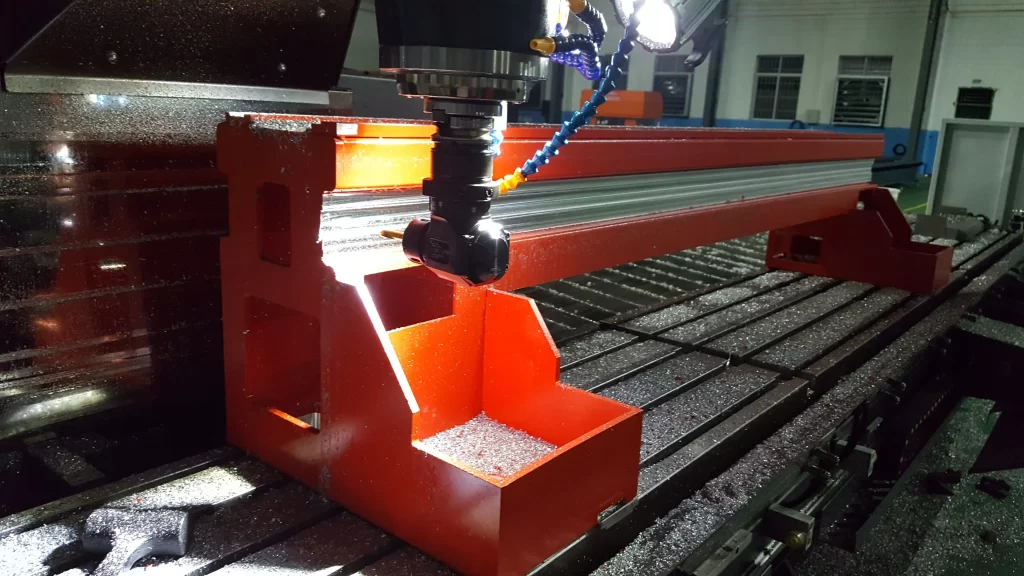

Quality control in high-precision CNC machining relies on specialized tools tailored to specific needs, each offering unique precision and applications:

- Coordinate Measuring Machine (CMM)

- Uses contact or non-contact methods to capture 3D geometric data.

- Ideal for complex shapes and reference parts, with accuracy up to 0.1 μm, commonly used in CNC machining centers.

- Laser Scanner

- Generates high-resolution point clouds non-invasively, perfect for complex surfaces and mold inspection in new energy vehicle parts processing.

- Fast but sensitive to material reflectivity.

- Optical Comparator

- Magnifies parts for 2D feature analysis, suited for small components or edge profiling in 5G equipment manufacturing machines.

- Surface Roughness Tester

- Measures Ra and Rz parameters for surface finish evaluation, available in portable or stationary models.

- Micrometers and Calipers

- Quick tools for measuring simple dimensions, achieving 1 μm accuracy for on-site checks.

- Porosity Tester

- Assesses material strength and wear resistance, often used for post-machining validation in industrial CNC processing equipment.

Selecting trusted CNC machining center suppliers ensures high-precision CNC machining equipment quality inspection with reliable, long-lasting tools.

3. Core Inspection Techniques

3.1 In-Process Inspection

- Monitors dimensions in real time during high-precision CNC machining, minimizing part misalignment and rework.

- Ideal for multi-axis machining and critical components, supporting CNC machining automation.

3.2 Statistical Process Control (SPC)

- Uses control charts to analyze production trends and adjust parameters promptly.

- Ensures consistency in high-volume production, a staple of CNC machining solutions.

3.3 Non-Destructive Testing (NDT)

- Techniques: Radiography, X-ray, and magnetic particle inspection.

- Detects internal flaws and hidden defects.

- Common in titanium alloy components for aerospace precision machining.

3.4 Optical and Vision Systems

- AI-powered image recognition automates defect and dimensional deviation detection.

- Suited for complex surfaces and large-scale production, enhancing efficiency for CNC machining center suppliers.

CNC machining automation detection technology integrates AI and IoT to streamline inspection processes significantly.

4. Implementation Strategies

- Inspection Planning

- Select tools and techniques based on part characteristics.

- Define clear targets (e.g., Ra values, dimensional tolerances).

- Environmental Control

- Temperature: 20±1°C

- Humidity: 40-60%

- Prevents thermal expansion or optical interference.

- Equipment Calibration

- Regularly validate accuracy with standard reference parts.

- Log and adjust parameters to maintain minimal deviation, relying on CNC machine brands for reliability.

- Data Management

- Build traceable databases.

- Use SPC to analyze trends and optimize workflows.

Partnering with cost-effective CNC machining center suppliers ensures equipment meets high-precision CNC machining demands.

5. Industry Applications

5.1 High-Precision CNC Machining Equipment Quality Inspection in Aerospace

Turbine blade inspection combines Coordinate Measuring Machines (CMMs) with Non-Destructive Testing (NDT). CMMs verify micron-level tolerances for complex geometries, while NDT (e.g., ultrasonic or X-ray) detects internal cracks or voids, ensuring reliability under extreme conditions in aerospace precision machining.

5.2 Medical Devices Surface Quality Inspection

Artificial joints demand exceptional surface finish. Surface roughness testers ensure Ra values below 0.1 μm, and optical comparators magnify tiny surface flaws, guaranteeing biocompatibility and performance.

5.3 Automotive Manufacturing CNC Machining Consistency

Engine component production relies on Statistical Process Control (SPC) to monitor dimensional variations and in-process inspection to reduce rework, ensuring stable output for automotive manufacturing CNC machines.

5.4 Mold Processing

Complex mold surfaces are inspected using laser scanners to generate 3D point clouds, compared against CAD models to verify precision, supporting precision mechanical processing equipment.

6. Challenges and Solutions

1: Complex Geometries

- Solution: Integrate CMMs with laser scanners for multi-sensor inspection.

2: High Inspection Costs

- Solution: Adopt CNC machining automation detection technology, streamline processes, and use in-process inspection to minimize handling and rework, reducing CNC machining center price burdens.

3: Operator Skill Gaps

- Solution: Implement standardized operating procedures (SOPs) and regular training.

4: Data Silos

- Solution: Leverage IoT for equipment connectivity and big data analytics to enhance process optimization, supporting CNC machine manufacturers.

7. Conclusion and Recommendations

Quality inspection for high-precision CNC machining balances accuracy, efficiency, and cost:

- Complex Geometries: Prioritize CMM and laser scanner integration.

- Small-Batch Production: Use automated CMMs with SPC to cut costs.

- Surface Finish Control: Combine optical inspection and roughness testing.

- Budget Planning: Invest in versatile, high-value equipment from reputable CNC machine manufacturers.

By aligning inspection tools and techniques with data-driven management, high-precision CNC machining can significantly boost product performance and market competitiveness. Optimized processes also help control CNC machining center prices, delivering greater value.