Practical Tips to Boost CNC Machining Center Efficiency

In modern precision manufacturing, the CNC machining center stands as a cornerstone of production. Whether it’s a CNC Gantry Milling Machine or a CNC Profile Machining Center, its operational efficiency directly impacts production cycles, cost control, and delivery timelines. Yet, many manufacturers still grapple with common challenges: low machine utilization, long changeover times, short tool life, and bloated NC programs.

This article dives deep into seven key areas—process design, tool management, fixture optimization, programming strategies, equipment maintenance, operator practices, and auxiliary systems. Drawing on real-world data and industry-standard terminology, we’ll explore actionable, practical techniques to enhance CNC machining center performance and drive measurable cost savings.

1. Optimize Machining Process Design

1.1 Streamline Operations and Toolpaths

Smart process planning is the foundation of efficiency in CNC machining. The principle of operation concentration—performing multiple machining steps on a single machine—can drastically cut down on setup frequency and material handling time.

For instance, using a 5-axis CNC machine to mill, drill, and tap five sides of a complex aerospace component in one setup can reduce setup time by over 40% compared to a traditional 3-axis machine requiring three or more setups (based on actual data from an aerospace parts factory).

Beyond setup reduction, optimizing toolpaths is crucial. Conventional back-and-forth cutting introduces excessive non-productive motion and abrupt direction changes, disrupting machine dynamics. Instead, advanced High-Speed Machining (HSM) strategies—such as trochoidal milling, helical interpolation, and adaptive roughing—ensure smoother, more consistent cutting, minimizing tool stress.

Example: Deep Slot Milling in 45# Steel

- Traditional linear cutting: Feed rate F = 800 mm/min, spindle speed S = 2000 rpm → Cycle time: 3.2 minutes per slot

- Trochoidal path (φ12 tool, ae = 0.3D): Feed increased to F = 2200 mm/min, S = 3500 rpm → Cycle time drops to 1.6 minutes → 50% faster, with 30% less tool wear

For aluminum profile machining, specialized Aluminum Profile CNC Machines deliver superior precision and throughput, making them ideal for high-volume architectural and industrial applications.

1.2 Optimize Cutting Parameters

Properly tuned cutting parameters—cutting speed (Vc), feed per tooth (fz), axial depth of cut (ap), and radial width of cut (ae)—are essential for balancing productivity and tool life. Over-aggressive settings risk tool breakage or spindle overload, while overly conservative ones lead to inefficient “rubbing” instead of cutting.

Example: Machining 7075-T6 Aluminum

- Recommended Vc: 800–1200 m/min (carbide tools)

- fz: 0.15–0.3 mm/tooth

- For a φ10 mm 4-flute end mill, spindle speed can reach ~38,000 rpm (requires a high-speed spindle)

Real-time spindle load monitoring helps maintain optimal performance. Ideally, spindle load should stay between 60% and 80%. A case study from an automotive parts plant showed that reducing ap from 2.5 mm to 1.8 mm while increasing fz from 0.1 to 0.18 mm/tooth dropped spindle load from 92% to 75%. This adjustment extended tool life by 40% and reduced cycle time by 12%.

1.3 Minimize Non-Cutting Time

Non-cutting time—encompassing tool changes, rapid movements, and program startup—can consume 20–40% of the total cycle time (per German VDI 3423 standards). Reducing this idle time is critical for boosting overall efficiency.

Key Tactics:

- Optimize tool change sequences: Arrange tool calls in logical order to minimize Z-axis travel. Group roughing, finishing, and drilling tools to reduce T-code jumps.

- Optimize G00 rapid positioning: Ensure the shortest possible path to avoid unnecessary motion.

- Pre-load programs and tools: Load the next program and pre-install tools during the final stages of the current job to enable seamless transitions.

One home appliance manufacturer cut average tool change time from 18 seconds to 11 seconds by refining toolpath logic. With 200 tool changes per day, this saved 2.3 hours of non-productive time daily.

2. Optimize Tooling Systems and Management

2.1 Select High-Performance Cutting Tools

Cutting tools are the “teeth” of any CNC operation—whether on a CNC Gantry Machining Center or a CNC Vertical Machining Center—and their performance directly dictates efficiency and surface quality.

Advanced Coated Tools have become standard in modern shops:

- TiAlN coating: Withstands temperatures up to 800°C, extends tool life by 2–3× vs. uncoated tools.

- AlCrN coating: Superior oxidation resistance, ideal for stainless steel and high-temp alloys—up to 4× longer life.

- PCD (Polycrystalline Diamond): Perfect for aluminum and composites, enabling cutting speeds over 3000 m/min.

Specialized High-Efficiency Tools:

- High-Feed Milling (HFM) cutters: Feature large radius edges, allowing feeds of 0.4–1.0 mm/tooth (vs. 0.05–0.2 mm for standard end mills). For example, a HFC tool in P20 mold steel achieves F = 4000 mm/min, ap = 0.5 mm, ae = 6 mm, delivering a material removal rate (MRR) of 1200 cm³/min—3× faster than conventional tools.

- Drill-mill combo tools: Combine drilling, chamfering, and face milling in one operation, reducing tool changes. One manufacturer reduced tool count from 5 to 2 for a flange part, cutting tool changes by 60%.

2.2 Implement Tool Presetting and Life Management

Tool presetting is a game-changer for setup efficiency. Using external presetters , operators can set tool length and diameter offsets off-machine, slashing on-machine setup time from 10–15 minutes to under 2 minutes.

Tool life management should be data-driven:

- Maintain a tool life database (e.g., φ8 end mill lasts 60 minutes or 120 parts in 45# steel).

- Use tool life counters in the CNC system to trigger alerts or automatic tool changes.

- Integrate cutting force monitoring to detect tool wear or breakage in real time.

One auto parts plant reduced unplanned downtime by 35% and tool waste by 28% after implementing a tool life tracking system. This strategy is a cornerstone of maximizing a CNC machining center’s uptime.

2.3 Match Tools to Toolpaths and Applications

Selecting the right tool geometry for each feature is critical:

- Ball nose end mills: Best for 3D contouring, but inefficient for roughing—avoid using them for bulk material removal.

- Corner radius end mills: Balance strength and surface finish, ideal for rough-finishing in molds.

- Long-reach tools: For deep cavities, but reduce spindle speed by 20–30% if tool overhang exceeds 4× diameter to prevent chatter.

Rule of thumb: Tool overhang (L) ≤ 4× tool diameter (D). Beyond this, use anti-vibration tool holders (e.g., Silent Tool, Big Kaiser Hyper Mill) or adopt step-down machining. Proper tool selection is fundamental to a productive CNC machining center.

3. Optimize Fixturing and Workholding

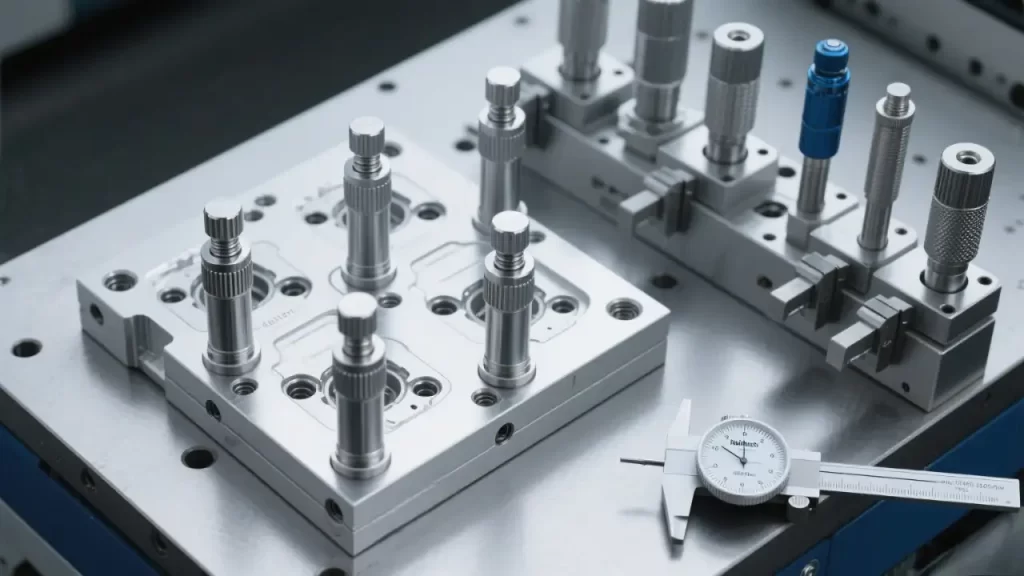

3.1 Use Standardized, Modular Fixturing

Custom fixtures are often costly and slow to change. Modular fixturing systems enable “15-minute changeovers” regardless of part complexity.

Zero-point systems achieve repeatability ≤ 0.005 mm via hydraulic or mechanical clamping. When paired with Automatic Pallet Changers (APC), they enable 24/7 unmanned operation.

One mold shop slashed changeover time from 2 hours to 25 minutes, boosting Overall Equipment Effectiveness (OEE) from 58% to 76%. This level of efficiency is a hallmark of a well-run CNC machining center.

3.2 Minimize Setups and Maximize Accuracy

Single-setup, multi-face machining is the gold standard for efficiency. 5-axis CNC machining allows complex parts to be fully machined in one go, eliminating cumulative errors from multiple setups.

Example: Impeller Machining

- 3-axis machine: 4 setups, total time: 4.5 hours

- 5-axis machine: 1 setup, total time: 2.1 hours → 53% faster, with better geometric tolerances

Best Practice: Use a common datum (e.g., one flat surface and two dowel pins) across all operations. Employ in-process probing to automatically compensate for setup deviations and improve first-part yield. This precision is what sets a high-performance CNC machining center apart.

3.3 Optimize Fixturing for High-Volume Production

For mass production, multi-station fixtures dramatically boost throughput.

Example:

- An 8-station pneumatic fixture processes 8 small housings in one setup.

- With high-speed cutting, cycle time per part is 0.8 minutes, total processing time 7 minutes. → 8× effective throughput increase

Flexible fixturing systems further reduce changeover time by accommodating multiple part families. This flexibility is key to a competitive CNC machining center.

4. Optimize CNC Programming and CAM Strategies

4.1 Leverage Advanced CAM Strategies

Modern CNC programming software offers powerful strategies—especially critical for specialized applications like CNC Machine for Window & Door and CNC Machine for Facade Fabrication.

Adaptive Roughing:

- Dynamically adjusts cut width and feed to maintain constant load.

- Eliminates air cutting, especially in pocket clearing.

- Field tests show 40% faster material removal and 30% longer tool life vs. traditional Z-level roughing.

Rest Machining:

- Only cuts leftover material from previous tools.

- Avoids redundant full-area passes, saving 15–25% time.

Finishing Strategy Combos:

- 3D surfaces: Constant Z-level + parallel + projection milling

- Flat areas: High-speed trochoidal finishing

- Edges: Small-radius tools for deburring and edge smoothing

The quality of your programming directly impacts the output of your CNC machining center.

4.2 Simulate and Verify Programs

NC program simulation is essential to prevent costly collisions and overcuts. Tools like Vericut or built-in CAM simulators enable:

- 3D collision checks (tool, fixture, workpiece)

- Material removal visualization

- Reverse G-code validation

One shop avoided a $200,000 spindle replacement by catching a φ20 tool collision in simulation. After implementing mandatory simulation, such incidents dropped to zero. Simulation is a non-negotiable step for a reliable CNC machining center.

4.3 Optimize Post-Processing

The post-processor translates CAM toolpaths into machine-specific G-code. Custom post-processors can:

- Merge consecutive G01 moves to reduce program lines.

- Automatically insert coolant commands and tool offsets.

- Generate clean, efficient code to prevent buffer overflows.

One program was compressed from 12,000 to 8,500 lines, cutting read time by 30%—especially beneficial for older control systems. Efficient code is vital for a smooth-running CNC machining center.

5. Equipment Maintenance and Condition Monitoring

5.1 Implement Preventive Maintenance (PM)

Machine reliability hinges on disciplined maintenance. A structured PM plan should include:

- Daily: Clean linear rails, check lubrication, inspect chip conveyors.

- Monthly: Test spindle drawbar force (12,000–18,000 N), check ball screw preload.

- Quarterly: Use laser interferometers to verify positioning accuracy (ISO 230-2), compensate for backlash.

One factory reduced monthly downtime from 18 to 6 hours after adopting a formal PM schedule. A rigorous PM plan is the bedrock of a dependable CNC machining center.

5.2 Optimize Spindle and Drive Systems

The spindle is the heart of a CNC vertical milling machine. Regular checks include:

- Spindle runout: Measure with a dial indicator; should be ≤ 0.003 mm when cold.

- Thermal growth compensation: High-end controls support thermal models to minimize drift.

Servo systems require periodic checks of encoder feedback and ball screw backlash (>0.01 mm needs adjustment). The health of these systems defines the precision of your CNC machining center.

5.3 Use Real-Time Monitoring

Modern CNC systems support data collection and analytics:

- FANUC FOCAS, Siemens SINUMERIK Operate log spindle load, feed rates, and alarms.

- Integrate with MES to calculate OEE = Availability × Performance × Quality.

One plant found a machine’s OEE was only 52%, primarily due to long program setup times. After optimization, it rose to 74%. Real-time monitoring transforms a CNC machining center from a machine into a smart factory asset.

6. Optimize Operator Practices and Management

6.1 Standardize Workflows (SOPs)

Detailed Standard Operating Procedures (SOPs) cover:

- Program loading (from PDM systems, version checks)

- Tool installation sequence and torque specs (e.g., 35 Nm for hydraulic chucks)

- First-article inspection (dimensions, surface finish, GD&T)

SOPs reduce errors and ensure consistency across shifts. Standardization is key to predictable results from a CNC machining center.

6.2 Train Operators Continuously

Training should include:

- Tool identification and selection (ISO 13399 standards)

- Program structure (G/M codes, subroutines)

- Troubleshooting (tool breakage, alarm resolution)

One company improved average operator skill by 40% and cut errors by 55% using a skills matrix. A skilled workforce is the most valuable component of any CNC machining center.

6.3 Optimize Scheduling and Planning

Adopt lean scheduling:

- Group similar parts to reduce changeovers.

- Pre-load programs and tools before the previous job ends.

- Use APS (Advanced Planning & Scheduling) software to optimize job sequences.

One plant cut daily changeovers from 12 to 6, boosting productive time by 18%. Efficient planning maximizes the utilization of the CNC machining center.

7. Optimize Auxiliary Systems and Environment

7.1 Improve Cooling and Chip Removal

- High-Pressure Cooling (HPC): ≥70 bar pressure flushes chips and extends tool life—+50% life in stainless steel.

- Chip conveyors: Spiral or scraper types must run 24/7 to prevent chip buildup and overheating.

7.2 Control the Environment

- Temperature: Maintain 20±2°C to minimize thermal expansion.

- Humidity: 40–60% to prevent condensation.

- Oil mist collectors: Improve air quality and operator health.

7.3 Integrate Automation

For high-volume production:

- APC systems: ≤30-second pallet exchange.

- Robotic loading/unloading: With vision guidance for full automation.

- ATC expansion: Increase tool capacity from 24 to 60+ to reduce manual intervention.

One company increased daily output from 120 to 210 parts per machine, cutting labor costs by 60%. Automation is the future of the CNC machining center.

Conclusion: Efficiency is a System, Not a Single Fix

Boosting CNC machining center efficiency isn’t about one magic solution—it’s a system-wide effort across process, tooling, fixturing, programming, maintenance, and people.

Establish a performance dashboard with KPIs like:

- OEE ≥ 80%

- Cycle time trending downward

- Tool cost ≤ 5% of total production cost

With data-driven decisions, standardized processes, and continuous improvement, your CNC machining center can achieve true high-performance manufacturing. Real efficiency? It’s built one optimized detail at a time.