Pick the Best CNC Machine Tools: Expert Tips for Smart Choices

The newly bought CNC Machining Center keeps letting you down: when machining aluminum, the Aluminum Profile CNC Machine wastes a lot of power; when you want to take on precision orders, the high-precision CNC equipment can’t keep up with the tolerances. Choosing CNC machine tools is never as simple as just checking parameters. It has to align perfectly with your materials, order volume, and even future plans. This guide will teach you to avoid these pitfalls and find the “just right” one.

1. Define Your Machining Needs and Goals

Start by clarifying your requirements to zero in on the right industrial CNC equipment like Aluminum Profile CNC Machine and avoid wasting your budget.

- Material Type: For metal machining (e.g., aluminum or steel), opt for high – power spindles, ideal for automotive manufacturing CNC machines. Plastics or carbon fiber demand flexible tooling. Knowing your material narrows your options. When dealing with aluminum, a machine like Aluminum Profile CNC Machine might be a great fit.

- Machining Type: Milling excels for complex shapes, while turning suits cylindrical parts. Multi – axis machining is key for intricate geometries, especially in aerospace precision machining, where a CNC machining center shines. Different CNC Machine Tools such as CNC Lathes are better suited for specific machining types.

- Production Scale: Small – batch runs call for versatile mid – sized machines, while high – volume production demands efficient CNC machining solutions. Assess order volume and delivery timelines to gauge equipment needs. For high – volume production, CNC Gantry Milling Machine could be considered due to its potential for high – speed and efficient operation.

- Precision Requirements: High – precision parts, like those for new energy vehicle components, require micron – level accuracy. Less demanding tasks can prioritize cost over precision. Strike a balance between budget and performance. High – precision CNC equipment like CNC Vertical Machining Center is often preferred for such high – precision jobs.

2. Understand Types of CNC Machine Tools

Different CNC machine tools have unique strengths. Knowing their capabilities helps you match the right precision machining equipment to your needs.

- CNC Milling Machines

These use rotating tools to cut complex shapes, molds, or curved surfaces. With multi – axis (3 – axis or more) capabilities, they handle flat surfaces, slots, and 3D structures. Widely used in automotive manufacturing CNC machines and aerospace precision machining, they’re perfect for diverse designs. CNC Machining Center often falls into this category with its ability to perform various milling operations. - CNC Lathes

Here, the workpiece rotates while the tool stays fixed, ideal for shafts, threads, or round parts. Fast and suited for high – volume production (e.g., bolts), they’re common in rail transit component machining. - CNC Machining Centers

These versatile machines combine milling, drilling, and tapping, with automated tool changers to minimize manual work. Perfect for complex parts, like those in 5G equipment manufacturing, they boost efficiency. CNC Gantry Machining Center is also a type of machining center that offers specific advantages for certain applications. - Other Types

Laser cutters excel at precision cutting of thin metal or non – metal materials. Plasma cutters use high – temperature arcs for thick metal, common in heavy industry.

3. Key Parameters for Choosing CNC Machine Tools

Performance specs determine whether a CNC machine tool meets your needs. Evaluate these to ensure you select high – precision CNC equipment.

- Spindle Speed and Power

Spindle speed (measured in RPM) affects cutting efficiency—higher speeds suit softer materials like aluminum. Power (in kilowatts) determines capability for hard materials like steel, critical for aerospace precision machining. Match these to your material. When using CNC Gantry Milling Machine for hard materials, sufficient spindle power is crucial. - Worktable Size and Load Capacity

Worktable size dictates workpiece compatibility—large molds may need over 1 square meter. Load capacity supports heavy parts (e.g., engine components). Verify workpiece dimensions and weight. Different CNC Machine Tools such as CNC Machining Center come with varying worktable sizes and load capacities. - Control System

The control system is the brain of a CNC machine tool, impacting precision. Fanuc is user – friendly and reliable, Siemens excels in complex programming, and Heidenhain is ideal for high precision. Consider your team’s expertise and upgrade support. - Tool Magazine Capacity

A larger tool magazine (20+ tools) enhances CNC machining automation by enabling automatic tool changes, ideal for complex tasks. This is an important feature in machines like CNC Machining Center.

CNC Machine Tool Performance Comparison Table

| Parameter | Ideal Use Case | Key Considerations |

|---|---|---|

| Spindle Speed | Soft materials, high – speed | High speeds may increase tool wear |

| Spindle Power | Hard materials, heavy cutting | Ensure adequate power supply |

| Worktable Size | Large parts | Oversized tables raise costs |

| Load Capacity | Heavy parts | Verify structural stability |

| Control System | User habits, complex coding | Check software compatibility |

| Tool Magazine Capacity | Multi – step, complex parts | Larger capacity increases costs |

4. Budget and Cost Management

Balancing performance and cost ensures your CNC machine tool delivers a strong return on investment.

- Initial Investment

New machines offer reliability and warranties but come at a premium. Used machines can cost half as much (e.g., mid – sized CNC machining centers range from $30,000–$70,000 new, $15,000–$35,000 used). Assess needs to decide. You can find different price ranges for various CNC Machine Tools like CNC Vertical Machining Center based on whether they are new or used. - Operating Costs

Power consumption is a major expense—high – power machines can rack up thousands in monthly electricity bills. Opt for energy – efficient models. Maintenance (e.g., servicing and tool replacement) costs thousands quarterly. Ensure CNC machining center suppliers provide timely spare parts. Machines like CNC Gantry Milling Machine with high power may have higher operating costs. - Software and Training

Programming software like Mastercam costs thousands. Operator training runs $700–$3,000. Factor in software and training needs. - Budget Planning Tips:

- New vs. Used: Choose used for tight budgets, new for reliability.

- Operating Costs: Prioritize energy – efficient machines.

- Software: Check if it’s included.

- Training: Include training in your budget.

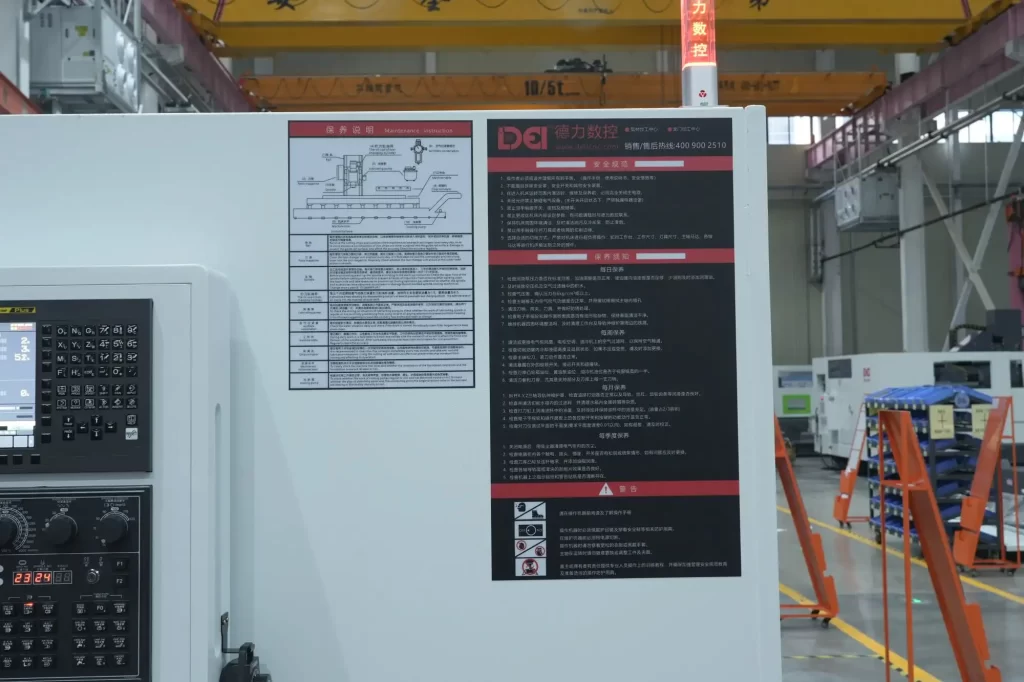

5. Choosing Brands and Suppliers

Picking a reliable CNC machine tool and CNC machine manufacturer ensures performance and support.

- Brand Strengths

Top CNC machine manufacturers excel in precision and CNC machining technology innovation. Some specialize in high – precision CNC equipment for aerospace precision machining, while others offer cost – effective solutions. Match brand strengths to your needs, like rigid machining centers for automotive or mold work. Different brands may be associated with specific CNC Machine Tools such as CNC Machining Center. - Supplier Services

Look for responsive after – sales support, fast spare parts delivery, and technical training to speed up onboarding. Contact CNC machining center suppliers to confirm their service network. - User Reviews and Case Studies

Customer feedback reveals real – world performance. Check forums or video reviews for insights on durability and precision. Case studies, especially for new energy vehicle components, highlight proven applications. Prioritize CNC machine brands with strong track records. - Selection Criteria:

- Machining Needs: Choose precision brands for high – accuracy tasks, efficient models for mass production.

- After – Sales: Verify repair and parts availability.

- Feedback: Review user experiences and case studies.

6. Plan for Future Scalability

Choose CNC machine tools that adapt to future needs and technological advancements.

- Modular Design

Modular systems allow upgrades, like moving from 3 – axis to 5 – axis machining, without replacing the machine. Check for support of control modules or add – ons like rotary axes. This is an important aspect to consider when looking at CNC Machine Tools for long – term use. - Compatibility

Ensure your CNC machine tool supports modern tools and fixtures, such as HSK or BT tool holders, to enhance CNC machining automation flexibility. Different CNC Machine Tools may have different levels of compatibility with modern tools. - Automation Integration

Machines compatible with robotics or automated production lines enable unmanned operations, like auto – loading systems. Confirm support for robotic interfaces or pallet systems. CNC Machining Center may offer better options for automation integration in many cases. - Scalability Checklist:

- Modular Support: Can it upgrade to more axes?

- Tool Compatibility: Does it support modern tool holders?

- Automation Readiness: Is it equipped for production line integration?

7. On – Site Evaluation and Testing

Hands – on testing confirms your CNC machine tool delivers on promises, maximizing your investment.

- Visit Showrooms

Observe the machine in action, noting noise, vibration, and speed. Low noise and stable spindles signal quality craftsmanship. Verify space and cooling requirements. When visiting showrooms, you can check out different CNC Machine Tools like CNC Lathes and CNC Milling Machines. - Trial Machining

Test with a sample workpiece to check precision and surface finish. Measure tolerances (micron – level) or inspect cut surfaces to assess precision machining equipment reliability. Use a sample workpiece relevant to your intended use, such as for new energy vehicle components when evaluating a machine for that specific application. - Technical Consultation

Discuss your use case (e.g., 5G equipment manufacturing) with engineers to get tailored tooling or programming advice, ensuring the machine fits your needs. Consult engineers about the best CNC Machine Tools for your specific use case.

This guide equips you with the knowledge to choose CNC machine tools that align with your goals, balancing performance, cost, and future – readiness.