Linear Motion Systems: How Bearings & Rails Enable Precision Engineering

A linear bearing is the unsung hero of modern mechanical engineering, gliding like a virtuoso skater to guide objects along a straight path with minimal friction. Whether it’s keeping the spindle assembly humming smoothly in a CNC router or ensuring a 3D printer’s print head hits micron-level precision, linear bearings work their magic behind the scenes.

Paired with a linear rail, they deliver a trifecta of speed, accuracy, and stability to mechanical systems. From industrial automation to the sliding doors in your home, this tech is everywhere, reshaping how we think about efficient motion. Let’s dive into the types, workings, applications, and the pros and cons of linear bearings to explore this engineering marvel.

Types of Linear Bearings

Overview of Common Types

Linear bearings come in a variety of flavors, each tailored to specific tasks and performance needs. In high-precision fields like CNC machining, picking the right type is make-or-break. Here’s the lowdown on three heavy hitters: ball bearings, roller bearings, and slide bearings, with a peek at what makes each tick.

Ball Bearings

A linear ball bearing is like the nimble sprinter of motion systems. It uses steel balls that roll in a loop between the slide and the linear rail, slashing friction to a minimum. These balls are held in a precision cage to keep them evenly spaced and avoid any bumper-car chaos. The result? Top-notch speed and accuracy, perfect for light to medium loads. You’ll find them in compact CNC routers, supporting the spindle motor to keep tools zipping along smoothly. Their small size makes them a go-to for tight spaces, like the guts of a 3D printer.

Roller Bearings

If ball bearings are sprinters, a linear roller bearing is the armored tank. Instead of balls, it uses cylindrical rollers that spread out the load over a larger contact area, handling heavier weights with ease. The rollers glide along the linear rail, distributing pressure evenly to cut down on wear. This durability and stiffness make roller bearings shine in rugged setups, like supporting slides on a heavy duty linear rail. In industrial automation, they’re the muscle behind moving hefty workpieces or robotic arms, keeping things steady under serious strain.

Slide Bearings

A linear slide bearing is the quiet workhorse of the bunch. No rolling parts here—just direct contact between the slide and the linear rail, with low-friction materials like Teflon coatings or self-lubricating polymers keeping things slick. Simple and budget-friendly, these bearings thrive in harsh conditions, like scorching heat or corrosive environments. They’re quieter too, but they can lag in high-speed or ultra-precise tasks. You’ll spot them in low-speed, heavy-duty gear, like manual adjustment rigs or chemical processing machines.

Key Differences Between Types

Ball bearings, roller bearings, and slide bearings each bring something different to the table, with trade-offs in friction, load capacity, and versatility. Ball bearings excel at low friction and high speed, ideal for quick-response jobs, but they’re not built for super-heavy loads. Roller bearings dominate in high-load, high-rigidity scenarios, though they’re bulkier and demand precise installation. Slide bearings win on simplicity and toughness in tough environments, but their higher friction can drag efficiency in fast-moving systems.

Maintenance is another dividing line. Ball and roller bearings need regular lubrication to stay smooth—skimp on it, and performance tanks. Slide bearings, thanks to their material makeup, are more forgiving but can lose precision as surfaces wear over time. Ball and roller systems are also pickier about dust and debris, requiring seals, while slide bearings shrug off grit better. Choosing one means weighing these factors against your project’s needs.

Applications for Each Type

Each linear bearing type has its moment to shine. A linear motion bearing like a ball bearing is a staple in CNC routers and 3D printers, keeping the spindle or print head gliding with pinpoint accuracy. In CNC work, they ensure tools move along linear rails and bearings without a hint of vibration, locking in top-quality results.

Roller bearings are the go-to for heavy lifting, like in massive automation lines or logistics setups. Paired with sturdy linear rails and slides, they support beefy machine parts with zero wobble. In car manufacturing, roller bearings handle molds weighing tons, keeping production humming.

Slide bearings thrive in niche settings, like food processing plants or chemical factories, where metal ball lubricants might be a no-go. They’re also common in low-speed applications, like sliding doors or manual tool benches, where their straightforward design cuts maintenance costs. Knowing what each type brings helps you dial in the perfect setup.

How Linear Bearings Work

The Basics of Linear Motion

At its core, a linear bearing is all about making straight-line motion as smooth as skating on ice. In CNC machining, this lets tools or workpieces slide along a fixed path with errors measured in microns. Unlike rotational motion, linear motion has to wrestle with gravity, inertia, and external loads while keeping energy waste low.

Linear bearings use rolling elements or low-friction surfaces to turn clunky sliding into a streamlined glide. This boosts the efficiency of a spindle assembly and extends the life of the linear rail and linear slide. In precision tasks, that smoothness is what separates a flawless part from a scrapped one.

Why Linear Motion Needs Special Design

Straight-line motion sounds easy, but it’s a beast to get right. Without optimization, sliding surfaces can grind, overheat, or seize up. Picture dragging a metal block across another—resistance piles up fast, bleeding energy. Linear bearings cut that drag to the bone with rolling elements or slick materials, letting a spindle motor drive the system with minimal effort. This is critical for high-speed or long-haul jobs, where heat or wear could throw off accuracy.

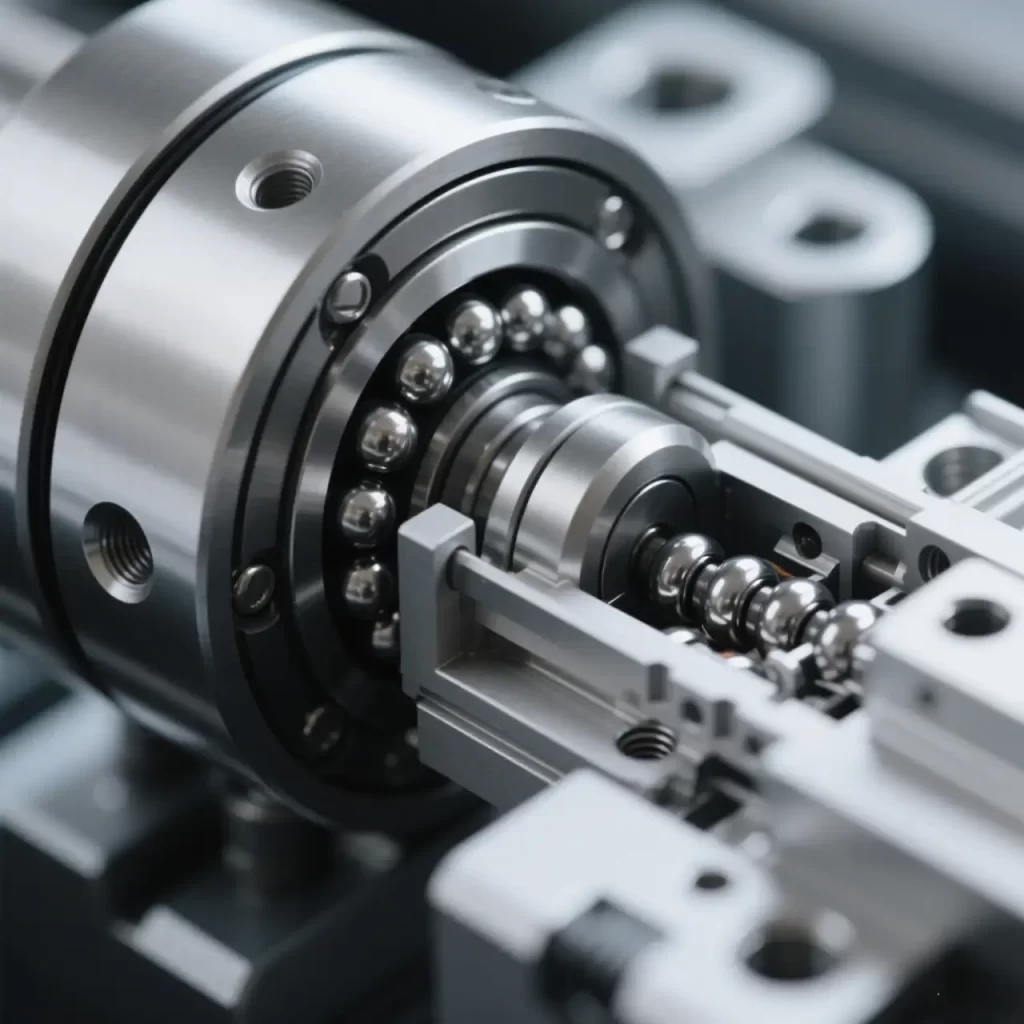

Components of a Linear Bearing System

Think of a linear bearing system as a finely tuned band, with the linear rail, slide, and rolling elements jamming together to nail perfect motion. Here’s the breakdown of these key players.

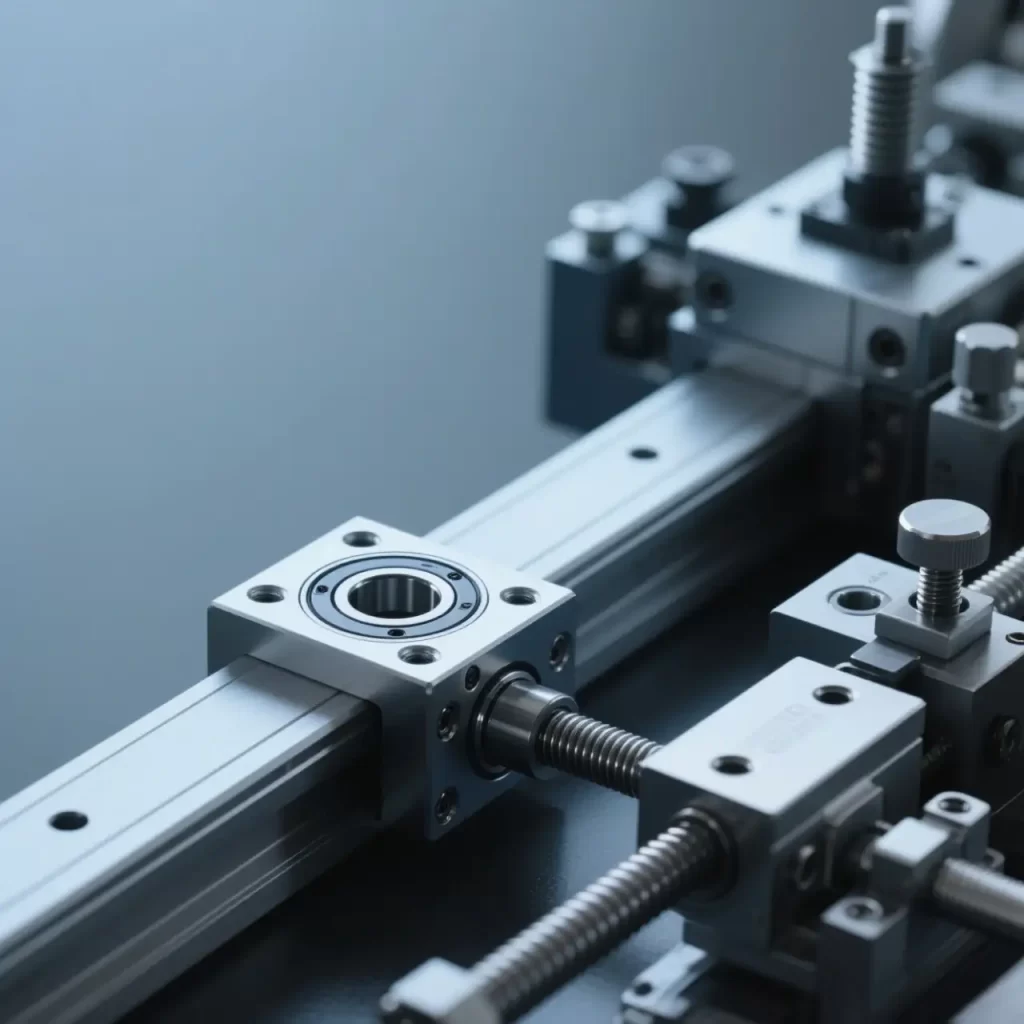

Linear Rail

The linear rail is the backbone, setting the path and keeping things on track. Made from high-strength steel or aluminum alloy, its surface is ground to near-perfect flatness and smoothness. In a CNC router, the linear rail takes the weight of the spindle and cutting forces while holding micron-level stability. They come in shapes like rectangular, round, or dovetail slot—a trapezoidal design that adds extra grip—depending on load and precision needs. Top-tier rails resist bending and rust, built for the long haul.

Slide

The linear bearing slide is the mover, dancing along the linear rail while carrying the workload. It’s packed with rolling elements or uses a low-friction surface to stay in sync with the rail. The slide’s design dictates how much weight it can handle and how smoothly it moves. In CNC setups, it works hand-in-hand with the spindle support to keep tool paths dead-on. Lightweight slides are built for speed, while heavier ones tackle bigger loads. Material and machining precision here are make-or-break for performance.

Rolling Elements

Rolling elements are the secret sauce in many a linear motion bearing, with steel balls or rollers stealing the show. They roll between the slide and linear rail, dropping friction to next to nothing. Balls are nimble, great for light loads and high speeds in compact linear rails and bearings. Rollers are beefier, built for heavy-duty linear slides. Their quality, size, and layout matter big-time—good ones spread force evenly, dodging wear and boosting lifespan.

How Friction Gets Tamed

Rolling Beats Sliding

The magic of a linear ball bearing lies in its rolling action. Steel balls or rollers cruise along the linear rail, touching it just enough to keep friction laughably low. It’s like rolling a cart versus dragging a plank—way less effort. In CNC gear, this lets a linear rail bearing handle fast, nonstop motion without overheating, keeping the spindle assembly safe. Rolling also sharpens response time, making the system quick on its feet.

Lubrication’s Role

Lubrication is the silent guardian of low friction. Linear bearing systems use grease or oil to coat the linear rail and rolling elements, forming a thin film that keeps things slick. This cuts wear and wards off rust. In high-speed or heavy-load setups, like big CNC router spindles, regular lube checks are non-negotiable to stay in top form. Some high-end designs use self-lubricating materials or sealed systems, cutting down on upkeep and boosting reliability.

Materials and Surface Treatments

The right materials and finishes are the unsung heroes of a linear bearing’s performance. Linear rails and slides often use hardened steel, polished to a mirror-like shine to minimize drag. Some systems step it up with ceramic balls or polymer coatings for even better friction control. Ceramic balls are light and corrosion-resistant, ideal for high-speed jobs, while Teflon coatings let slide bearings run smooth even without lube. These tricks keep systems humming in brutal conditions—think scorching heat, dust, or humidity—opening up a world of possibilities.

Where Linear Bearings Shine

Industrial Machinery

CNC Routers

CNC routers are where linear bearings flex their muscles. Linear rails and slides steer the spindle or worktable, ensuring tools carve complex paths with surgical precision. Low-friction linear ball bearings let the tools snap to commands fast, while keeping vibrations at bay to nail accuracy. The spindle motor leans on these parts for micron-level positioning, cutting everything from aluminum to titanium. Quality linear bearings also stretch the spindle assembly’s lifespan, trimming maintenance costs.

Robotics

Industrial robots rely on linear bearings for slick, straight-line moves. Whether welding, assembling, or hauling materials, a linear rail bearing keeps robot joints steady, delivering razor-sharp repeatability. On auto assembly lines, robots use linear slides for spot welds with errors under a millimeter. Linear roller bearings are clutch in high-load setups, supporting heavy grippers without a hitch. Their toughness lets robots grind through intense production schedules.

Transportation Systems

Trains

Trains tap heavy duty linear rails to fine-tune critical components. Modern high-speed rail doors or suspension adjusters might use a linear bearing slide for butter-smooth operation. These parts shrug off vibrations, temperature swings, and years of wear, with low-friction designs boosting reliability and rider comfort. A door’s linear rail, for instance, might use a slide bearing for whisper-quiet opening, cutting maintenance needs.

Automated Guided Vehicles

Automated guided vehicles, or AGVs, are logistics superstars, and linear bearings are their secret weapon. Linear rails and bearings guide AGVs along set paths, hauling heavy loads with ease. Low-friction linear motion bearings keep them energy-efficient and dead-on in tight spaces. In Amazon warehouses or car plants, linear slides make automated logistics faster and smarter.

Consumer Products

3D Printers

3D printers are a poster child for linear bearings in consumer tech. The print head needs to zip along X and Y axes, stacking material layers at micron scales. Linear rails and slides, paired with compact linear slides, keep the head’s path flawless. A linear ball bearing’s low friction makes printing fast and quiet while locking in high resolution. From hobbyists to pro studios, linear bearings make 3D printing dependable and slick.

Sliding Doors

Sliding doors may seem basic, but they owe their smooth glide to a linear bearing slide. From home glass doors to mall automatics, a linear rail keeps the door moving effortlessly. High-end setups might use a dovetail slide—a trapezoidal rail for extra stability—to prevent derailment. Slide bearings bring durability and low upkeep, standing up to years of use, especially in high-traffic spots.

Pros and Cons

Advantages of Linear Bearings

High Precision

A linear motion bearing is a precision powerhouse. Linear rails and slides are machined to keep errors in the micron range, critical for CNC routers. A spindle leaning on a linear ball bearing can churn out complex parts where a hair’s breadth off means scrap. Rolling elements keep motion steady, cutting vibrations for rock-solid performance.

Low Friction

Low friction is a linear bearing’s calling card. Rolling elements turn sliding drag into tiny rolling resistance, slashing energy waste. In CNC setups, this lets a spindle motor run lean while staying cool. It also smooths out motion, extending the life of linear rails and bearings, especially in high-speed jobs.

Durability

Linear bearings are built to last. Hardened steel linear rails and slides are treated to fight wear and rust. Rolling elements spread loads evenly, dodging stress points. On a heavy duty linear rail, systems can log thousands of hours without flinching. Smart lubrication and shielding stretch that lifespan further, keeping costs down.

Challenges of Linear Bearings

Maintenance Needs

Linear bearings demand upkeep to stay sharp. Linear ball bearing systems need lube to keep friction low—let dust or neglect creep in, and you’re risking jams. In CNC work, linear rails and slides face chips and coolant, so cleaning and lubing are musts. Slide bearings are lower-maintenance but can lose precision as surfaces wear. Maintenance time and costs are real considerations.

Load Limits

Load capacity varies by type. Ball bearings handle light to medium loads fine but buckle under extreme weight. Linear roller bearings take on heavier stuff, but they’re bulkier and pricier. Slide bearings excel with static loads but lag in high-frequency motion. Pick a linear rail bearing that doesn’t match your needs, and you’re courting trouble.

Cost Considerations

Top-tier linear bearings don’t come cheap. Precision linear rails and slides require complex manufacturing, driving up costs. Ball and roller systems outprice slide bearings, especially for custom or specialty materials. For cash-strapped projects, budget linear slides might tempt, but they could lag in long-term performance. Balancing upfront spend with durability is the name of the game.

Choosing the Right Linear Bearing

Picking a linear bearing means juggling multiple factors. Load is job one—heavy tasks call for roller or heavy duty linear rails and bearings, while lighter ones vibe with a linear ball bearing. Speed and frequency matter too—high-speed setups need low friction, but slow, heavy jobs might lean toward slide bearings.

Environment’s a big player—dusty or corrosive settings demand seals or special coatings. Budget and maintenance capacity shape choices too; high-end systems cost more upfront but might save long-term. Don’t forget install space or how it’ll mesh with your spindle support. Nail these, and you’ve got the perfect fit.