How to Prevent CNC Machine Coolant from Going Bad: Causes & Fixes

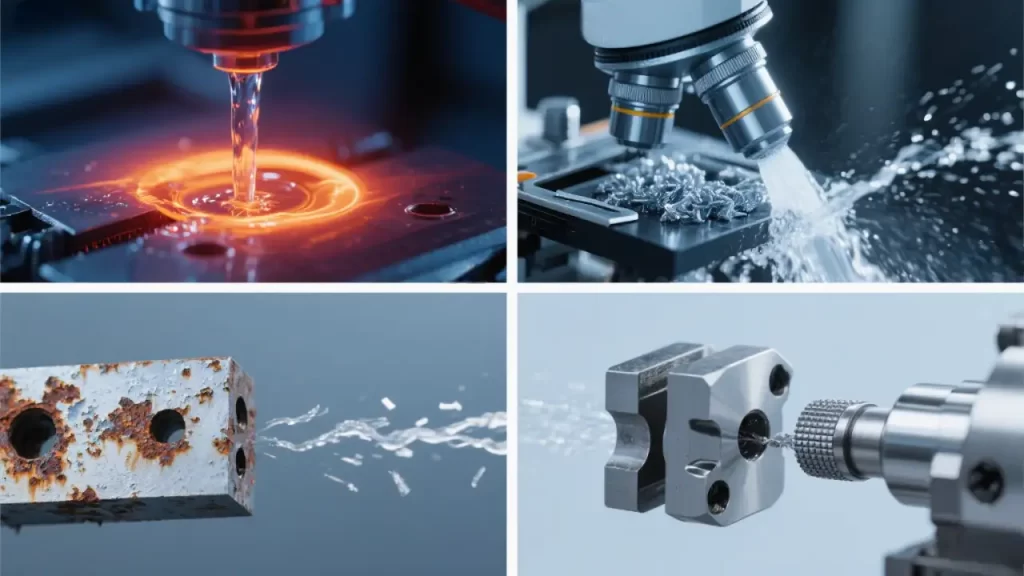

In modern metal cutting manufacturing, cnc machine coolant plays a critical role in maintaining machining precision, extending tool life, and ensuring equipment stability. In high-load, continuous operations on metal CNC machines, including CNC milling machines, CNC lathes, and 5-axis CNC machines, the coolant is constantly exposed to high temperatures, humidity, and contamination from metal ions—conditions that easily trigger chemical breakdown and microbial growth, leading to performance degradation or even system failure.

Industry data shows that over 60% of CNC machining shops have experienced unplanned downtime, abnormal tool wear, or workpiece corrosion due to improper cnc machine coolant management. In many cases, maintenance costs related to coolant issues account for more than 30% of total fluid usage expenses. As a result, understanding the degradation mechanisms of cnc machine coolant and establishing a scientific system for monitoring, treatment, and prevention has become essential for achieving efficient, stable, and sustainable manufacturing.

This article provides a comprehensive analysis of the full lifecycle management of cnc machine coolant, covering fluid types, signs of degradation, root causes, detection methods, corrective actions, and advanced management strategies—helping manufacturers enhance the reliability and cost-effectiveness of their CNC machining services.

2. The Role and Importance of CNC Machine Coolant

In metal CNC machining, cnc machine coolant performs four key functions:

- Heat Dissipation: Cutting generates extreme heat—often exceeding 800°C locally. Cnc machine coolant carries this heat away through continuous circulation, maintaining thermal stability.

- Lubrication and Friction Reduction: Minimizes friction between the tool and workpiece, reducing cutting forces and improving surface finish.

- Chip Removal: Flushes chips out of the cutting zone, preventing re-cutting and nozzle clogging.

- Rust and Corrosion Protection: Shields workpieces, fixtures, and machine components (e.g., guideways) from oxidation.

In high-load operations such as CNC milling and CNC turning, the performance of cnc machine coolant directly impacts the yield rate and cost control of CNC machining services. However, over time, cnc machine coolant is highly susceptible to degradation, which can lead to a cascade of production issues.

3. Types and Composition of CNC Machine Coolant

According to ISO 6743-7, water-based cnc machine coolant is primarily classified into three categories, each widely used across various metal CNC machines:

| Type | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|

| Soluble Oil (Emulsion) | General turning, drilling | Good lubricity, low cost | Prone to bacterial growth, emulsion breakdown |

| Semi-Synthetic | CNC milling, grinding | Balanced performance, high clarity | Sensitive to water quality |

| Full Synthetic | High-precision, aluminum machining | Excellent stability, strong cooling | Lower lubricity, requires additives |

3.1 Key Additives in CNC Machine Coolant

Modern cnc machine coolant is a complex multi-phase system. Its stability and performance depend on a blend of functional additives:

- Emulsifiers: Maintain stable oil-in-water (O/W) emulsions

- Corrosion Inhibitors: e.g., benzotriazole (BTA), protect ferrous and non-ferrous metals

- Extreme Pressure (EP) Additives: Form protective films under high loads

- Biocides: Suppress microbial growth

- pH Buffers: Maintain alkaline conditions (pH 8.5–9.5) to inhibit acidification

- Defoamers: Prevent foam buildup that impairs cooling and lubrication

The balance and stability of these components directly determine the service life of cnc machine coolant in metal CNC machining environments.

4. Signs of CNC Machine Coolant Degradation

Degradation of cnc machine coolant is a gradual process, typically accompanied by visible, olfactory, and performance-related warning signs.

4.1 Visual Changes

- Darkening or Cloudiness: Color shifts from milky white to gray or dark brown

- Phase Separation: Oil layer on top exceeds 2mm, indicating emulsion breakdown

- Excessive Foaming: Persistent foam that doesn’t dissipate

- Slime or Floc Formation: Indicates microbial biofilm development

4.2 Odor Issues

- “Rotten Egg” Smell: Caused by hydrogen sulfide (H₂S) from sulfate-reducing bacteria (SRB)

- Sour or Acidic Odor: Result of organic acid production by lactic acid bacteria

Studies show that once bacterial counts in cnc machine coolant exceed 10⁵ CFU/mL, noticeable odors typically develop.

4.3 Performance Deterioration

- pH Drop: Falling below 8.0 indicates acidification, increasing corrosion risk

- Concentration Fluctuations: Abnormal refractometer readings suggest dilution or additive loss

- Reduced Rust Protection: Rust spots on chips or workpieces

- Poor Lubricity: Accelerated tool wear, increased surface roughness

5. Root Causes of CNC Machine Coolant Degradation

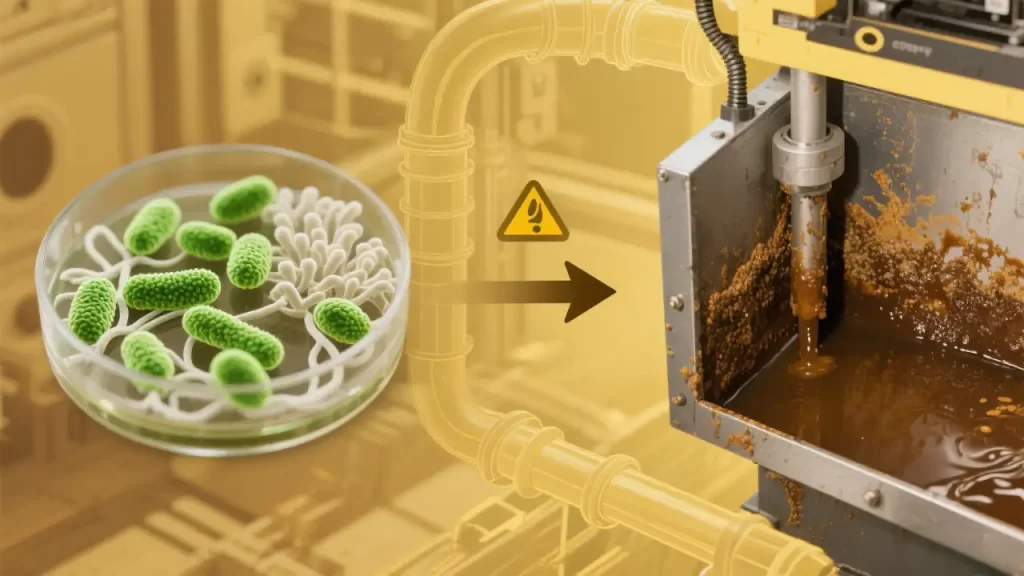

5.1 Microbial Growth: The Primary Culprit

Water-based cnc machine coolant contains carbon and nitrogen sources, along with water—making it ideal breeding grounds for bacteria, fungi, and yeast. In hot, humid shop environments, cnc machine coolant can quickly become a microbial incubator.

Key Microbial Contaminants:

- Aerobic Bacteria: e.g., Pseudomonas, break down emulsified oils and produce organic acids

- Anaerobic Bacteria: e.g., Clostridium, produce H₂S in oxygen-deprived zones, causing corrosion

- Fungi and Yeast: Form viscous biofilms that clog filters and pumps

Tests show that untreated cnc machine coolant in summer conditions can see bacterial counts rise from 10³ to 10⁷ CFU/mL within just 7 days—far exceeding the ISO 13759 limit of 10⁵ CFU/mL.

5.2 Chemical Breakdown and Oxidation

High temperatures accelerate the aging of cnc machine coolant. During CNC milling or CNC turning, localized heat can trigger:

- Auto-oxidation Chain Reactions: Generate peroxides, aldehydes, ketones, and carboxylic acids

- Metal Catalysis: Iron and copper ions dramatically speed up oxidation rates

- Hydrolysis: Ester-based additives break down in high-heat, high-moisture environments

5.3 External Contamination

Tramp Oil

Leakage from machine way oils or hydraulic systems introduces tramp oil. When tramp oil exceeds 2% of total volume:

- Promotes anaerobic bacterial growth

- Disrupts emulsion stability

- Reduces cooling efficiency due to insulating oil layer

Metal Chips and Powder

Fine metal particles adsorb additives, reducing their effective concentration. They also serve as substrates for microbial attachment and biofilm formation.

Human and Environmental Contaminants

- Sweat, cleaning agents, or tap water accidentally entering the system

- Dust and microbial spores settling from the air

- Use of untreated hard water, leading to calcium and magnesium soap precipitation

5.4 Poor Management and Operator Errors

- Inconsistent Concentration: Too high encourages microbial growth; too low reduces lubricity

- Improper Replenishment: Adding water directly instead of pre-mixed fluid disrupts additive balance

- Lack of Maintenance: Failure to clean sumps, replace filters, or monitor pH/concentration

- Excessive Fluid Life: Some shops extend fluid use beyond 12 months—well past the recommended 6–9 month lifespan

6. Detection and Monitoring Methods

Establishing a robust monitoring system is key to early detection and prevention.

6.1 Routine On-Site Checks

- Concentration Testing: Use a refractometer; record daily trends

- pH Measurement: Normal range is 8.5–9.5

- Visual and Olfactory Inspection: Check for color, foam, and odor changes

6.2 Laboratory-Level Analysis

- Microbial Testing: Plate count method or ATP bioluminescence assay (results in minutes)

- Tramp Oil Content: Centrifuge test or infrared (IR) spectroscopy

- Conductivity & TDS: High readings indicate ionic contamination or additive breakdown

6.3 Smart Monitoring Systems

More CNC machining shops are adopting real-time monitoring:

- Install pH, conductivity, and temperature sensors

- Use AI algorithms to predict degradation trends

- Set threshold alerts for automatic maintenance notifications

One automotive parts manufacturer extended cnc machine coolant life by 30% and reduced unplanned downtime by 45% after implementing such a system.

7. Treatment Methods for Degraded Coolant

Apply tiered treatment strategies based on severity.

7.1 Mild Degradation (Bacteria < 10⁵ CFU/mL)

- Adjust concentration and pH

- Add biocides

- Use oil skimmers to remove surface tramp oil

7.2 Moderate Contamination (Bacteria 10⁵–10⁶ CFU/mL)

- Microfiltration or centrifugal purification

- Chemical cleaning to remove biofilms

- Replenish 10–20% fresh fluid to restore stability

7.3 Severe Degradation (Bacteria > 10⁶ CFU/mL)

- Fully drain and clean the sump, pipes, and pump

- Soak system with alkaline cleaner for 2 hours to remove biofilm

- Refill with fresh cnc machine coolant, slightly above target concentration to compensate for initial losses

7.4 Waste Fluid Disposal and Environmental Compliance

Spent cnc machine coolant is classified as hazardous waste (HW09). Proper disposal includes:

- Oil-water separation

- Chemical demulsification

- Neutralization and precipitation

- Transfer to licensed waste handlers compliant with GB 8978-1996 and other regulations

8. Prevention Strategies

“Prevention over correction” should be the guiding principle.

8.1 Proper Fluid Selection

- Match fluid type to workpiece material (cast iron, aluminum, titanium)

- In hot, humid environments, prefer full synthetic or biocide-rich semi-synthetic fluids

- Ensure compatibility with metal CNC machine seals (e.g., avoid nitrile rubber degradation)

8.2 Standardized Usage Management

- Establish a cnc machine coolant management protocol

- Use automated mixing systems for precise concentration control

- Log all test data and track trends over time

8.3 Equipment Maintenance

- Install high-efficiency oil skimmers (≥5 L/h)

- Use multi-stage filtration (magnetic + paper bed + bag filters)

- Clean sump bottoms every 3 months

8.4 Operator Training

- Train staff to recognize early signs of degradation

- Prohibit random water addition or mixing of incompatible fluids

- Provide PPE (gloves, goggles) to protect against skin and respiratory irritation

8.5 Environmental Control

- Improve shop ventilation to reduce temperature and humidity

- Cover sumps to minimize dust and light exposure

- Avoid placing coolant tanks near heat sources

9. Advanced Management and Future Trends

9.1 Centralized Coolant Systems

Large CNC machining shops benefit from centralized systems that service multiple CNC mills and CNC lathes:

- Enables centralized filtration and biocide dosing

- Reduces per-machine maintenance

- Improves fluid utilization and reduces waste

9.2 Smart Monitoring Platforms

Integrate sensors with PLCs and cloud platforms for:

- Real-time data visualization

- Predictive maintenance alerts

- Automated work order generation

9.3 Eco-Friendly Fluid Development

Next-gen cnc machine coolant is trending toward:

- Biodegradable formulations

- Nitrite- and phenol-free chemistry

- High-concentration (20:1+) concentrates to reduce shipping and storage costs

9.4 Dry or Near-Dry Machining Alternatives

For certain applications, Minimum Quantity Lubrication (MQL) uses a fine mist of plant-based oil. While commonly used on wood CNC routers and similar non-metal cutting equipment, metal CNC machining still relies heavily on cnc machine coolant due to its superior heat dissipation and lubrication under high-stress conditions.

10. Frequently Asked Questions (FAQ)

Q1: What types of cnc machine coolant are available?

A: The main types are soluble oil, semi-synthetic, and full synthetic—each suited to different metal CNC machines and machining processes.

Q2: Do 5-axis CNC machines require special coolant?

A: Yes. Due to complex geometries and high thermal loads, 5-axis machines benefit from high-performance synthetic fluids with enhanced filtration and biocide systems.

Q3: How should coolant be handled when selling a used CNC machine?

A: Fully drain the old fluid, clean the system, and flush with a pre-treatment solution to prevent contamination for the next user.

Q4: How often should cnc machine coolant be replaced?

A: Typically every 6–9 months. With smart monitoring, some shops extend this to 12 months depending on load, environment, and maintenance practices.

11. Conclusion

Degradation of cnc machine coolant remains a critical issue affecting quality and efficiency in metal CNC machining. Root causes include microbial growth, chemical oxidation, external contamination, and poor management. By implementing scientific monitoring, tiered treatment, and proactive maintenance, manufacturers can significantly extend fluid life and reduce operational costs.

In operations involving CNC milling machines, CNC lathes, and 5-axis CNC machines, the stability of cnc machine coolant directly impacts machining accuracy and tool longevity. For technicians and managers in CNC machining shops, mastering the identification and mitigation of coolant degradation is now a core competency for uninterrupted production.

As smart manufacturing advances, cnc machine coolant management will become more intelligent, precise, and sustainable. Whether delivering custom CNC machining services or operating large-scale CNC manufacturing facilities, companies must treat cnc machine coolant as a vital component of their production ecosystem—managing it through its entire lifecycle to achieve high efficiency, reliability, and environmental res