How to Ensure the Precision of a CNC Machine Center

1. Introduction: Precision Is the Heartbeat of Your CNC Machine Center

In today’s precision manufacturing landscape, the CNC machine center — short for Computer Numerical Control machining center — isn’t just another piece of equipment. It’s the backbone of smart factories, where micron-level accuracy can make or break product performance, safety, and profitability.

Think aerospace turbine blades requiring ±5μm contour tolerances to avoid aerodynamic inefficiency — or orthopedic implants needing a surface finish of Ra 0.2μm to ensure biocompatibility and wear resistance. In these high-stakes industries, precision isn’t optional — it’s existential.

Beyond quality, precision drives efficiency. A machine center holding ±3μm positioning accuracy can slash scrap rates by 40% and cut annual maintenance costs by a quarter compared to a ±10μm unit. It reduces rework, minimizes inspection cycles, and accelerates time-to-market.

Many newcomers ask: “What is a CNC machining center?” Simply put, it’s a computer-controlled, multi-axis cutting system that integrates milling, drilling, boring, and sometimes turning — all in one setup. It’s the Swiss Army knife of metal removal, trusted in mold-making, medical, automotive, and aerospace sectors.

This guide unpacks the science behind precision — from mechanical design to thermal management, control algorithms to operator training — so you can build a bulletproof precision strategy for your CNC machine center.

2. Defining CNC Machining Center Precision: What Gets Measured Gets Managed

Positioning Accuracy

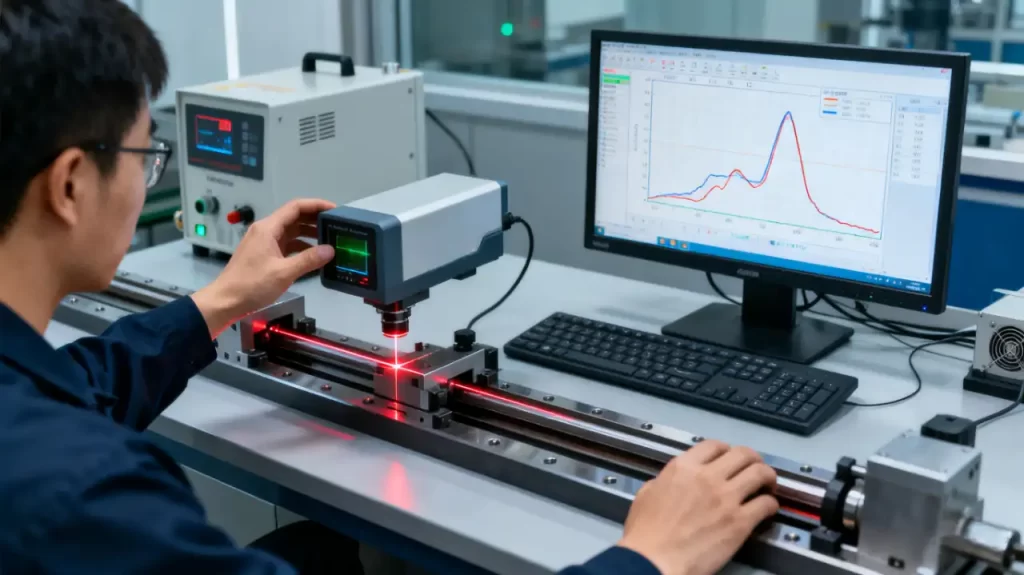

This measures how closely the machine’s axis reaches its commanded position. Tested per ISO 230-2 using laser interferometry, top-tier machines hold ±3μm over 300mm. Real-world example: if your X-axis shows +4.2μm overshoot and -3.8μm undershoot across 1,000mm, your unilateral accuracy is ±4.2μm.

Repeatability

How consistently can the machine return to the same point? Calculated as half the range of seven consecutive positioning attempts. Industrial-grade centers target ±1.5μm; ultra-precision models go below ±0.5μm. This metric is your best predictor of batch consistency.

Geometric Accuracy

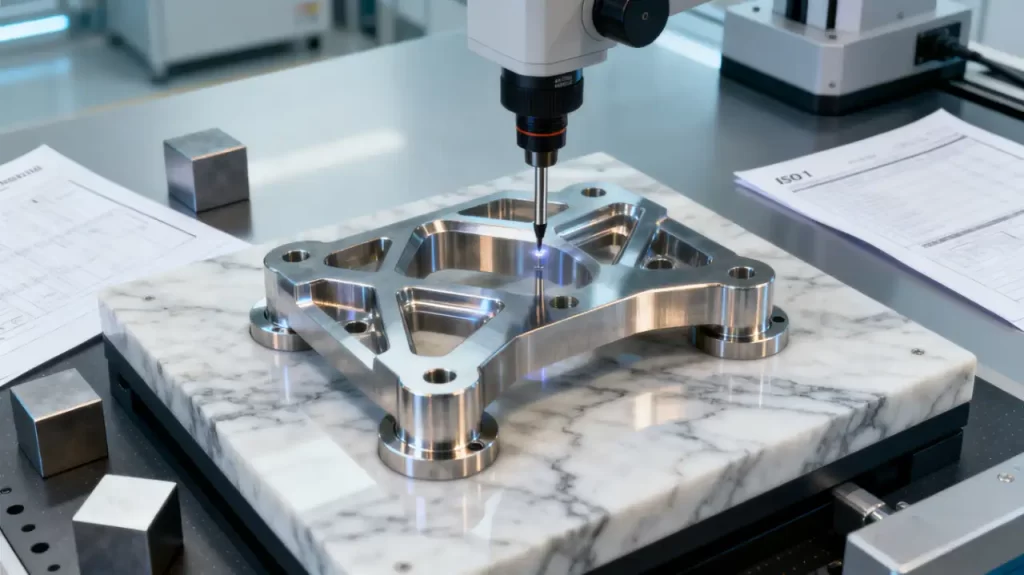

Static errors like straightness, squareness, and flatness matter just as much as motion accuracy. Per VDI 3441:

- Table flatness: ≤5μm over 1m²

- Spindle-to-table perpendicularity: ≤8 arcseconds

- Axis squareness: ≤10 arcseconds

Laser trackers or electronic levels map these errors into 3D compensation grids.

Dynamic Accuracy

Can your machine hold a perfect circle at 30m/min? Dynamic accuracy measures trajectory fidelity under acceleration, deceleration, and high feedrates. Ballbar testing per ISO 230-4 reveals circular deviation — high-performance centers keep it under 8μm for a Ø100mm test circle.

Surface Finish & Dimensional Tolerance

The final proof of precision. Surface roughness (Ra) depends on spindle speed, feed rate, tool nose radius, and coolant strategy. Dimensional drift? Blame thermal growth, tool deflection, or servo lag. Example: Skimp on thermal compensation during hardened steel finishing with CBN tools, and you’ll see 15–20μm of dimensional creep at >0.05mm depth of cut.

Global Standards You Can’t Ignore

- ISO 230 Series: The global benchmark for positioning, repeatability, thermal drift

- VDI 3441: Germany’s gold standard for geometric and volumetric error

- JIS B 6338: Japan’s rigorous acceptance protocol with strict thermal controls

- GB/T 17421: China’s equivalent to ISO, widely adopted in Asia

Always specify testing conditions: “20°C ±1°C, after 1-hour warm-up, unloaded.” Ambiguity invites disputes.

3. The Five Pillars of CNC Machine Center Precision

Mechanical Structure & Rigidity

Bed & Frame Design

Your machine’s foundation dictates everything. Cast iron (HT300+) offers superb damping but slow thermal response. Mineral composite beds (epoxy + granite) cut thermal expansion by 90% — perfect for climate-controlled labs. Monolithic gantry frames? 30% stiffer than bolted assemblies, ideal for resisting cutting forces.

For large-part machining, a CNC gantry type machining center delivers the span and stiffness needed for aerospace structural components.

Guide Systems: Pick Your Poison

- Roller Linear Guides: Low friction (0.002–0.003), adjustable preload, ±1μm repeatability — great for high-speed, light cuts

- Turcite-B Coated Box Ways: Massive contact area, vibration-damping — but needs scraping and perfect lubrication

- Hydrostatic Guides: Zero mechanical contact, ±0.5μm accuracy — complex and power-hungry, reserved for metrology-grade machines

Hydrostatics deform 5x less than linear guides under identical loads — critical for mirror-finishing or micro-machining.

Ball Screw Precision Control

JIS B 1192 grades C0 (top) to C10. C0 allows ≤±3μm cumulative lead error over 300mm. Eliminate backlash with dual-nut preloading (shim or tooth-differential), typically 10–15% of max axial load. Over-tighten? You’ll accelerate wear and heat. Smart move: pair with temperature sensors for dynamic preload adjustment.

Spindle Rigidity Engineering

Radial runout ≤1μm (per ISO 10817). “Four-in-front, two-in-back” angular contact bearing stacks are standard. Hydraulic or Belleville spring preload systems fine-tune stiffness. Ceramic balls (Si₃N₄) reduce centrifugal force by 30%, pushing DN values to 2.5 million — essential for 20,000+ rpm spindles.

Drive System Precision Control

Fighting Screw Thermal Growth

Ball screws expand with heat: ΔL = α·L·ΔT (α = 11×10⁻⁶/°C for steel). A 1.5m screw heating 10°C grows 165μm — enough to wreck tolerances. Countermeasures:

- Pre-stretch mounting to offset expansion

- Hollow-core, oil-cooled screws (ΔT < 3°C)

- Dual-loop control: scales measure table position directly

Servo Resolution Matching

23-bit absolute encoders (8.38M pulses/rev) deliver 0.0004° theoretical resolution. But mechanical backlash and compliance limit real-world accuracy. Set electronic gearing for ≤0.1μm pulse equivalents. Enable “flexible electronic gearing” to smooth acceleration shocks.

Backlash & Pitch Error Compensation

- Backlash Comp: Manually measure axis reversal lag in MDI mode, input into CNC parameter table

- Pitch Error Comp: Laser interferometer maps deviations every 50mm → compensation curve uploaded to CNC. Typical gain: ±15μm → ±3μm

Re-calibrate every 6 months — especially after relocation or overhaul.

Volumetric Error Compensation (VEC)

Single-axis fixes won’t cut it for skewed-axis coupling errors. VEC models 21 error terms (3 positioning, 6 straightness, 3 squareness, 9 rotary) using laser tracker grid data. Result? A 5-axis CNC machining center can leap from ±25μm to ±5μm spatial accuracy.

Thermal Stability: The Silent Killer of Precision

Heat Source Mapping

- Spindle motor: 40% of total heat, ΔT = 15–25°C

- Ball screw friction: 30%, gradient up to 8°C/m

- Coolant splash & ambient radiation: 20%

- Control cabinet: 10%

Thermal imaging shows Z-axis screws developing 12°C top-to-bottom differentials after 2 hours — tilting your table 0.02mm/m.

Thermal Compensation Systems (TCS)

PT100 sensors on screw nuts, spindle housings, and column walls feed real-time ΔT data to the CNC. Algorithms like ΔX = k·ΔT·L dynamically tweak coordinates. Real-world result: Aluminum thin-wall parts shrink from ±18μm to ±5μm variation.

Climate Control & Local Cooling

- Ambient ΔT ≤ ±1°C/h → target 20°C ±0.5°C

- Spindle: Oil-air lubrication + external chiller jacket (bearing ΔT ≤8°C)

- Screw covers: Forced air + copper cooling plates

- Cutting zone: Laminar nozzles blast heat away

Low-CTE Materials

- Granite bases (α=6×10⁻⁶/°C) vs. cast iron (α=11×10⁻⁶/°C)

- Invar scale mounts (α≈1.2×10⁻⁶/°C)

- Carbon fiber drawbars: 50% lighter, near-zero thermal drift

Control Systems & Software Compensation

Advanced Interpolation Algorithms

- Nano Interpolation: Splits blocks into 1nm micro-moves — kills low-speed crawl and contour chatter

- Look-Ahead: Pre-reads 500–1,000 blocks, smoothes feedrates — boosts circular accuracy by 40%

- S-Curve Acceleration: Replaces trapezoidal ramps — reduces inertial vibration, extends guide life

In-Process Metrology & Closed-Loop Feedback

- Workpiece probes: ±2μm repeatability for auto-alignment

- Tool breakage detection: Laser tool setters trigger alarms at ±3μm length deviation

- Adaptive machining: Adjusts depth of cut based on measured stock — maintains CPK ≥1.67

Compensation in Action

In a vertical CNC machining center, pitch error compensation can slash X-axis error from ±12μm to ±3μm. In a horizontal CNC machining center, focus on Y-axis squareness. For a precision CNC machining center, run full closed-loop + VEC as insurance.

| COMPENSATION TYPE | TARGETS | TYPICAL GAIN |

|---|---|---|

| Pitch Error | Non-linear lead | ±12μm → ±3μm |

| Backlash | Drive lash | 30% better circularity |

| Volumetric | 21 geometric errors | ±0.01mm RTCP in 5-axis |

| Thermal Drift | Heat-induced shift | 50% improved stability |

Validate quarterly with Renishaw QC20-W ballbar or API laser tracker.

Tooling & Workholding: Where Precision Lives or Dies

Toolholder Interface Grades

- HSK-A63: Dual-contact taper + face, ≤3μm runout @ 10,000 rpm

- Capto C6: Polygonal lock, 40% higher torsional rigidity — ideal for interrupted cuts

- Balance grade: G2.5 @ 20,000 rpm (minimum), G1.0 for fine finishing

Formula: Uₚₑᵣ = 9549 × G × M / n (g·mm). A 2kg holder at 20,000 rpm needs ≤0.95g·mm imbalance for G1.0.

Tool Length & Radius Compensation

- Tool presetter repeatability ≤1μm — recalibrate daily

- Include pull-stud to cutting edge in length comp — avoid Z-zero drift

- Use G41/G42 radius comp — but mind lead-in/out paths to prevent gouging

Zero-Point Clamping Systems

Cone-pin + drawbar modules deliver ±2μm repeatability. Pair with hydraulic fixtures for 5-second changeovers. For micron work, use smart fixtures with pressure feedback (±50N clamping force tolerance).

Fixture Rigidity & Vibration Control

- Baseplates: ≥30mm thick QT500 ductile iron

- Support posts: 3-point mounting — no over-constraint

- Clamping: Belleville spring constant-force units counter cutting-force spikes

- Ribbing & lightening holes tune modal frequencies away from spindle harmonics

For a CNC turn-mill center machine, fixtures must handle both rotational rigidity (turning) and vibration damping (milling). Dual hydraulic chucks + tailstock recommended.

Small shops? A small CNC machining center offers compact footprint, low energy use, and precision for low-volume, high-mix jobs.

4. Systematic Precision Management for Your CNC Machine Center

Installation & Commissioning

Foundation & Vibration Isolation

- Floor load capacity: ≥15 tons/m², flatness ≤0.05mm/m

- Rubber-metal isolators (natural freq. <10Hz) block crane vibrations

- Independent concrete piers ≥800mm deep — decouple from building structure

Factory Acceptance Report Review

Verify:

- Raw laser interferometer data (pre/post-compensation)

- Ballbar circularity plots (roundness, ovality)

- Spindle thermal growth curves (30/60/90-min idle runs)

Reject if any metric exceeds contract by 10%.

On-Site Recalibration & Compensation Upload

After 72-hour settling, use API T3 laser tracker per ISO 230-6 to remap 21 geometric errors → upload compensation file. This erases shipping-induced drift.

Preventive Maintenance & Recalibration

Lubrication Protocol

| COMPONENT | LUBRICANT | INTERVAL | NOTES |

|---|---|---|---|

| Linear guides / screws | Lithium EP2 grease | 500 hrs | No mixing brands |

| Spindle bearings | ISO VG10 spindle oil | Continuous mist | Oil temp ≤55°C, 3μm filter |

| Gearboxes | ISO VG220 synthetic | 2,000 hrs | Monitor wear particles via ferrography |

Monthly Ballbar Diagnostics

- Mount Ø100mm test ring

- Run G02/G03 arcs at F2000mm/min

- Analyze Renishaw software output (roundness, harmonic spectrum)

- If roundness >15μm or oval distortion appears — trigger geometry compensation

Annual Laser Recertification

Third-party lab tests per ISO 230-2:

- Axis positioning/repeatability

- Contouring accuracy under联动 motion

- Spindle thermal drift (log every 30 min × 4 hrs)

Re-sign acceptance after compensation updates.

Spindle Health Monitoring

- Radial runout: Capacitive sensor weekly — alarm >3μm

- Bearing preload: Hydraulic puller check every 2,000 hrs — torque ±5% of factory spec

- Noise analysis: FFT detects BPFI/BPFO bearing fault frequencies

For 4-axis CNC machining centers, monthly rotary table indexing checks prevent cumulative angular errors.

Process Optimization Tactics

Smart Cutting Parameters

- Milling: “Small radial, deep axial” (ae<0.3D, ap>2mm) — minimizes side deflection

- Turning: Constant surface speed (G96) — avoids chatter at outer diameters

- Drilling: Peck drilling (G83) with chip evacuation — prevents hole enlargement

Thermal Load Management

- Symmetrical toolpaths: Rough symmetrically, finish symmetrically — balances heat distribution

- Warm-up routines: 15-min dry runs before production — stabilizes thermal field

- Targeted cooling: MQL or 70-bar through-spindle coolant — hits the cutting zone

Vibration Suppression

- Force simulation: AdvantEdge or Third Wave predicts chatter thresholds

- Active damping fixtures: Piezo actuators cancel specific frequency bands

- Variable-pitch tools: Breaks up harmonic resonance

For CNC profile machining centers, combine contour-following paths with high-frequency spindles to avoid scalloping and chatter marks.

Environmental Control & Operator Training

Shop Floor Standards

- Temperature: 20°C ±0.5°C (precision zone), ±1°C (general)

- Humidity: 45–55% RH — prevents rust and static

- Cleanliness: ISO Class 8 (≤3.52M particles/m³ @ 0.5μm)

- Noise: <75 dB(A) — protects sensor accuracy

Standardized Operator Training

- Tool setting: Mandatory presetter use — no eyeballing

- Compensation input: Dual-verification protocol — test-cut after changes

- Simulation: VERICUT or NCBrain virtual machining — 100% collision coverage

- Troubleshooting: “Precision Incident Response SOP” — diagnose within 30 mins

Process Engineer Integration

- Join DFM (Design for Manufacturing) reviews — optimize part rigidity

- Create “Critical Feature Routing Cards” — define datums and stock allowances

- Implement SPC charts — monitor CPK, flag systemic drift

Final Thoughts: Precision Is a Culture, Not a Calibration

Your CNC machine center’s precision isn’t set once and forgotten. It’s a living system shaped by design, maintenance, process, and people.

When sourcing equipment, vet CNC machining center manufacturers for technical depth and local support. On a budget? Certified used CNC machining centers can deliver — but demand laser calibration reports. Negotiating CNC vertical machining center price? Clarify if installation, training, and Year 1 maintenance are included — hidden costs lurk everywhere.

Want to compare models for sale? Talk to specialists — match precision specs to your actual production needs.

Actionable steps:

- Build a precision logbook — track every calibration, repair, and drift event

- Adopt predictive maintenance — trigger service by OEE data, not calendar dates

- Invest in in-house metrology — ballbars and lasers reduce third-party dependency

- Cross-train your team — mechanics who understand G-code, programmers who know bearings

- Go digital — integrate MES for real-time precision analytics and AI-driven forecasting

In high-end manufacturing, your machine’s invoice value matters less than its ability to hold micron tolerances, day in, day out. That’s not just precision — that’s profit. That’s your competitive moat. That’s the real “money printer” of Industry 4.0.