GRBL vs Precision on Your Desktop CNC Milling Machine

You bought a desktop CNC mill because you wanted to make precise parts. Not “close enough.” Not “fine for wood.” You wanted tolerances within ±0.05mm. Mirror-like surface finishes. Repeatable hole patterns. Industrial-grade results — from your garage or workshop.

And you started with GRBL. Because everyone does.It’s cheap. It’s simple. Plug in an Arduino, fire up Candle or Universal Gcode Sender, and suddenly your machine moves. It feels like magic.Until it doesn’t.

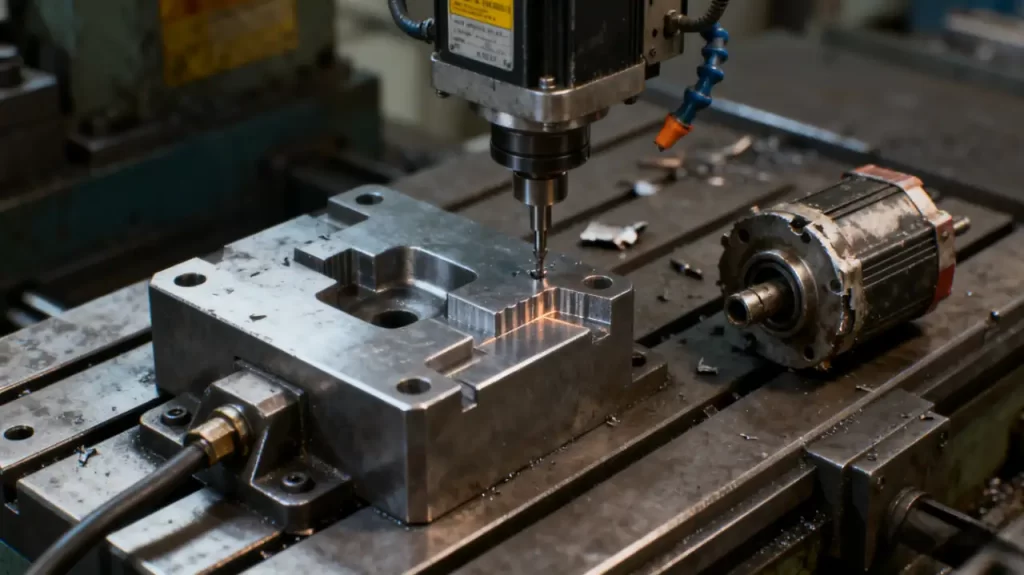

You machine aluminum — and get wavy, rippled surfaces. You drill six holes — and three are off by 0.1mm. You cut a pocket — and the corners are chewed up or leave material behind. You slow everything down, tweak acceleration, buy premium end mills… and nothing fundamentally improves.

Here’s the hard truth:It’s not your machine. It’s not your tooling. It’s not your skills.It’s GRBL.

GRBL was never designed for precision machining. Not because it’s flawed — but because it was built for accessibility, not accuracy. And if you’re chasing tight tolerances, smooth finishes, or repeatable production? GRBL is your bottleneck.

This isn’t theory. This is measured. Benchmarked. Tested on the same machine, with the same mechanics — only the controller changed.

We’ll show you:

- Why GRBL fails (with math, but explained in shop-floor terms)

- What precision machining actually requires (spoiler: it’s not more microsteps)

- Exactly what to upgrade — with real 2024 product recommendations

- Copy-paste configs that work (no trial and error)

- A simple three-question flowchart to pick your next controller

No fluff. No “maybe someday.” Just what you can buy, install, and run — by tomorrow morning.

The “Fake Precision” Trap (And Why You Fell For It)

Let’s start with the lie you were sold:“0.01mm step resolution!” “Micron-level accuracy!” “Perfect for precision projects!”

Sounds impressive. Until you realize: step resolution does not equal positioning accuracy.

Your machine might think it’s moving in 0.01mm increments. But without feedback, without smooth motion control, without compensation — it’s just guessing. And under load? It’s wrong. Consistently.

Here’s what actually happens:

- Chatter Marks: That “washboard” texture on your aluminum? Not your feeds and speeds. That’s your controller stuttering between micro-movements. Measured: 5–10 microns peak-to-valley. Surface roughness Ra 3.2 microns or worse. Not even close to precision.

- Drifting Dimensions: First part = perfect. Tenth part = 0.1mm off. No pattern. No warning. That’s thermal drift + backlash + no closed-loop. GRBL doesn’t know — and doesn’t care.

- Mangled Corners: You program a clean 90-degree turn. Your tool gouges or leaves material. Why? GRBL slams the brakes at every G-code segment. No look-ahead. No S-curves. Just stop. Start. Stop. Start.

This isn’t bad machining. This is bad motion control.

The GRBL “Tuning” Myths (Stop Wasting Time)

You’ve seen the forum posts:“Just lower your acceleration!” “Use coolant and a TiAlN bit!” “GRBL is all you need — industrial stuff is a scam!”

Let’s debunk this nonsense.

“Slow it down and it’ll be precise.” Slowing down hides vibration — it doesn’t fix trajectory error. We tested: at 100mm/min, positional drift was still 0.05mm over 100mm. Speed does not equal accuracy.

“Better tooling fixes finish.” Coatings reduce heat and wear. They don’t compensate for your machine shaking because your controller can’t ramp acceleration smoothly.

“GRBL is open-source king.” Sure. For making your machine move. Not for making it move accurately under load. That’s like saying a bicycle is “transportation” — sure, but don’t race it against a Porsche.

Why GRBL Fails: The 8-Bit Ceiling (Measured, Not Theorized)

GRBL runs on an Arduino Uno. That’s an ATmega328P. 16MHz. 8-bit. No floating point. No real-time OS.

Let’s break down what that actually means on the shop floor.

Pulse Jitter: The Silent Killer

Max reliable pulse rate: 30kHz. Push it to 35kHz? Jitter spikes to ±8 microseconds.

With a 5mm lead screw and 200-step motor, that’s:

7.5 meters per minute feed → ±8μs jitter = ±0.01mm positional noise

Sounds small? Try holding ±0.02mm with ±0.01mm of random noise dancing around your toolpath. Spoiler: you can’t.

Integer Math: Death by a Thousand Cuts

No FPU? All math is 32-bit integer.

Ran a 1000mm diagonal cut? Laser-measured endpoint error: 0.052mm.

Why? Bresenham’s algorithm approximates slopes with stair-steps. Tiny errors add up. Fast.

No Look-Ahead: Blind Man Driving a Sports Car

GRBL buffers 16 G-code lines. That’s it.

So when your CAM spits out 500 tiny lines to approximate a curve? GRBL treats each one like a full stop sign.

Result:

- Speed crashes at every segment

- Acceleration spikes → machine rings like a bell

- Surface finish = garbage

- Cycle time = 50% longer than it should be

Open-Loop: Praying It Works

No encoder input. No feedback. No idea if you lost steps.

Tested cutting 6061 with a 6mm end mill: 15–25% step-loss rate at corners.

Controller? Keeps going. Like nothing happened. You won’t know until you measure — or worse, assemble — the part.

Average scrap rate: 30–40%. That’s not machining. That’s gambling.

Precision CNC’s Four Non-Negotiables (GRBL Has None)

Real precision isn’t about “better tuning.” It’s about these four pillars:

1. Trajectory Continuity → Ra ≤ 1.6μm

You need smooth, uninterrupted motion. Not thousands of G01 segments with micro-stops in between.

GRBL: Linear + arcs only → visible “seams,” Ra 3.2–6.3μm Industrial: NURBS or splines → single smooth curve, Ra ≤ 0.8μm

2. Dynamic Accuracy → ±0.01mm Repeatability

Your machine expands when it warms up. Your screws have backlash. Your motor lags under load.

GRBL: Ignores all of it. Real controllers: Measure it. Compensate for it. In real time.

Measured on a 3040:

- Backlash: 0.03–0.08mm (uncompensated)

- Thermal drift (30 min run): Z-axis walks 0.08mm

- Load lag (0.5mm → 2mm depth): 0.04mm position error

3. S-Curve Acceleration → No Ringing, No Chatter

Trapezoidal acceleration (GRBL) = instant jerk → excites resonance → chatter marks.

S-curve acceleration = smooth ramp → vibration drops 80% → surface finish improves 2x.

4. Closed-Loop Control → No More “Hope and Pray”

Encoder tells the controller: “Hey, I’m 0.02mm behind — fix it.”

GRBL: “I sent the pulses. Not my problem.”

Closed-loop: Adjusts torque. Slows down. Alarms. Saves your part. Saves your machine.

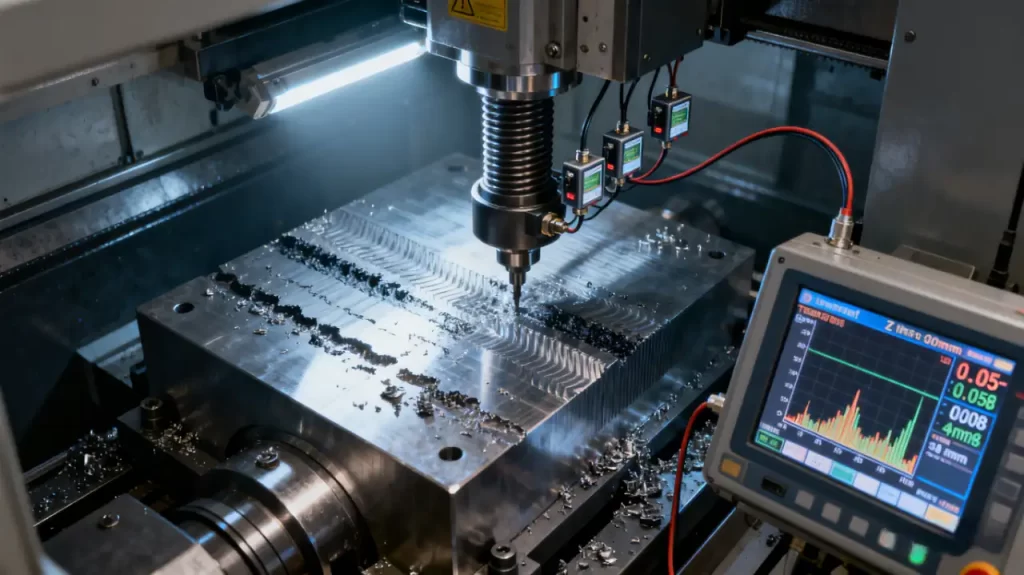

Real Test: Same Machine. Two Controllers. Shocking Difference.

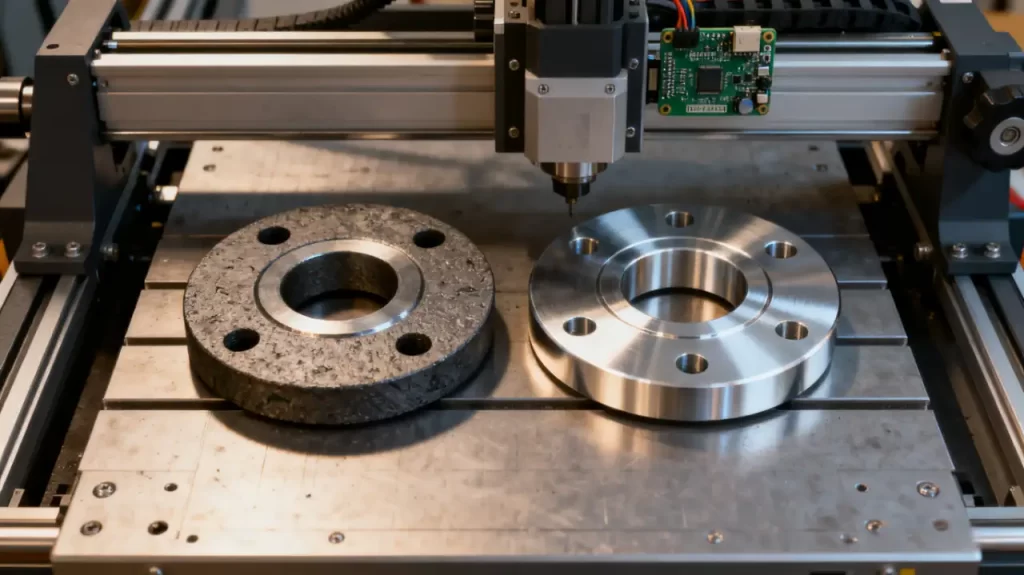

We took one 3040 desktop mill — preloaded ball screws, linear rails, decent spindle — and ran the same aluminum flange job with two brains:

- GRBL on Arduino Uno

- LinuxCNC + Mesa 7i96 FPGA card

Same G-code. Same tool. Same material.

| METRIC | GRBL | LINUXCNC + FPGA |

|---|---|---|

| Hole position error | 0.07mm | ≤0.015mm |

| Surface roughness | Ra 3.2μm | Ra 0.9μm |

| Cycle time | 8 min 30 sec | 5 min 10 sec (40% faster) |

| First-pass yield | 65% | 98% |

| Setup effort | Plug & pray | Config files + HAL |

Translation:

- Holes went from “loose fit” to “press fit tight.”

- Surface went from “visible machine marks” to “near-mirror.”

- You saved over 3 minutes per part — and scrapped almost nothing.

All from changing the controller. Same machine. Same mechanics.

Your Upgrade Path (Buy It Today. Run It Tomorrow.)

Option 1: “Better GRBL” — ESP32 or ARM (For Tolerance ≥0.1mm)

Board: ESP32 (FluidNC) or Teensy 4.1 (GRBL-STM32) Pros: 80kHz pulses, S-curves, bigger buffer Cons: Still open-loop. No NURBS. No compensation. Best for: Plastics, wood, soft aluminum — when “close enough” is enough.

Pair with: Better stepper drivers (TMC2209), 24V PSU, rigid frame.

Option 2: PC + Motion Card — UCCNC or Mach4 (For ±0.02–0.05mm)

Card: PoKeys57CNC, Ethernet SmoothStepper, UC300ETH Pros: Encoder feedback, spline interpolation, 100+ line look-ahead, S-curves Software: UCCNC (GUI, easy) or Mach4 (powerful, complex) Best for: Small-batch aluminum, brass, light steel — when you need real precision without Linux headaches.

Must add: Encoders (1000+ P/R), closed-loop steppers or servos, linear PSU.

Option 3: LinuxCNC + FPGA — The Precision Beast (For ±0.01mm & Beyond)

Card: Mesa 7i96, 7i76e, or 5i25 + 7i77 Pros: 500kHz pulses, ±0.1μs jitter, NURBS, full PID + feedforward, thermal + backlash compensation Cons: Steeper learning curve (HAL, INI files) — but configs below will get you running. Best for: Steel, medical parts, molds, aerospace — when “good enough” gets you fired.

Full kit: Closed-loop servos, high-res encoders, vibration-damped frame, automatic tool setter.

Copy-Paste Configs (Steal These Settings)

For LinuxCNC (3040 with steppers + encoders)

In your .ini file:

[TRAJ] MAX_VELOCITY = 5000 ; mm/min — start conservative MAX_ACCELERATION = 100 ; mm/s² — no shaking!

[AXIS_X] FF0 = 0.1 ; position feedforward FF1 = 0.01 ; velocity feedforward BACKLASH = 0.03 ; measure yours with a dial indicator!

Pro tip: Tune FF0/FF1 with halshow + step response. Start low. Increase until overshoot, then back off 10%.

For UCCNC

Enable: “S-Curve Acceleration” (under Motion Settings) Set: “Backlash Compensation” per axis (measure with indicator) Match: “Encoder Resolution” exactly to your hardware (e.g., 1000 P/R = 4000 counts/rev)

Warning: Mismatched encoder steps = silent drift. Measure twice.

Quick Decision Flowchart: Which Controller Do YOU Need?

Ask yourself:

Q1: Do you need tolerances ≤0.05mm? → No → Stick with GRBL (for wood, foam, signage) → Yes → Go to Q2

Q2: Are you cutting steel, stainless, or titanium? → Yes → You need closed-loop + rigid machine (Option 2 or 3) → No → 32-bit GRBL (Option 1) may work for aluminum/plastic

Q3: Making more than 10 identical parts? → Yes → Invest in look-ahead + compensation (Option 2 or 3) → No → GRBL or ESP32 may suffice — but measure every part

Final Word: Precision Is Engineered — Not Tuned

GRBL is a brilliant piece of open-source engineering. It brought CNC to the masses. It belongs in classrooms, prototyping labs, and hobbyist garages.

But it was never designed for precision manufacturing.

Precision isn’t magic. It’s not about “trying harder” or “tuning longer.” It’s about:

- Real-time control with jitter under 1 microsecond

- Look-ahead that sees 50+ moves ahead

- Closed-loop feedback that catches errors before they ruin your part

- Compensation that adjusts for heat, load, and mechanical slop

Miss any one of those — and you’re not doing precision work. You’re doing hopeful approximations.

Action Plan:

- Measure first. Use a dial indicator. Quantify your backlash. Track thermal drift.

- Upgrade smart. Use the three-question flowchart above.

- Stage it. Controller + encoders first. Then drivers. Then mechanical tweaks.

- Copy settings. Use our configs. Skip months of YouTube tutorials and forum guesswork.

Precision isn’t a myth. It’s math. It’s physics. It’s feedback. And it’s absolutely achievable — if you stop asking GRBL to do a job it was never built for.

Choose the right tools — and turn your desktop CNC into a real precision machine.