G Code and M Code: The Backbone of CNC Programming

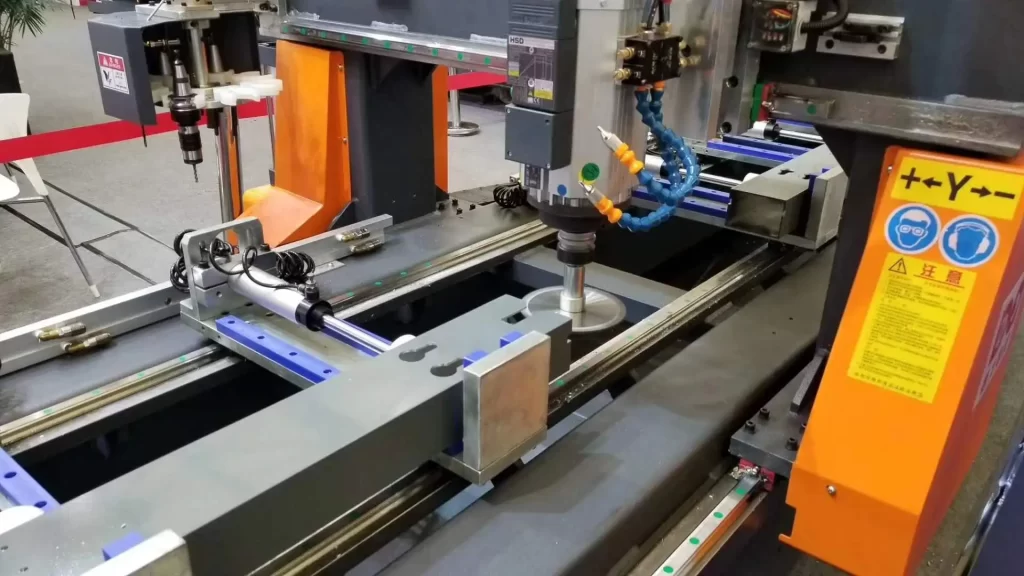

G code and M code are the cornerstones of CNC (Computer Numerical Control) programming, orchestrating tool movements and auxiliary functions to deliver precision and efficiency in machining. From CNC Machining Centers to specialized equipment like Aluminum Profile CNC Machines, these codes underpin every operation. This article explores their roles, differences, and synergy, with optimized keyword integration for technical clarity.

G-Code: Guiding Tool Motion

G-code (Geometric Code) directs the tool’s path across a workpiece, forming the heart of CNC programming. CNC programming G-code defines precise movements through coordinates (e.g., X, Y, Z) and parameters like feed rate (F), making it indispensable for CNC Gantry Milling Machines and CNC Vertical Machining Centers. It powers tasks such as linear interpolation (G01) or circular interpolation (G02/G03), critical for shaping parts in CNC Machine Shops and applications like Facade Fabrication.

Its modal nature—where commands like G90 (absolute positioning) persist until overridden—offers flexibility. G-code for surface machining excels at crafting complex geometries, from curved profiles in Window & Door CNC Machines to intricate details in CNC Router operations.

Common G-code commands:

- G00: Rapid positioning for non-cutting moves at maximum speed, used in setup for Metal CNC Machines.

- G01: Linear interpolation for straight cuts at a specified feed rate, vital for CNC Profile Machining Centers.

- G02/G03: Clockwise/counterclockwise circular interpolation, essential for arcs in Aluminum Profile CNC Machine workflows.

Highly standardized, G-code ensures compatibility across equipment, from basic routers to advanced CNC Gantry Machining Centers.

M-Code: Managing Auxiliary Functions

M-code (Miscellaneous Code) handles non-motion tasks, such as spindle control (M03/M05), coolant activation (M08/M09), or program flow (M00/M30). In CNC Machine Shops, CNC programming M-code streamlines operations—whether starting a spindle for Wood CNC Machines or pausing for tool changes in Metal CNC Machines.

Most M-codes are non-modal, executing once (e.g., M00 pauses until resumed), though exceptions like M03 (spindle on) are modal. They often use simple parameters (e.g., S for spindle speed), but compatibility varies by machine—critical for CNC Machines for Facade Fabrication with custom setups.

Common M-code commands:

- M03/M04: Spindle rotation (clockwise/counterclockwise), tailored to CNC Vertical Machining Centers and Wood CNC Routers.

- M05: Spindle stop, used during tool changes in Aluminum Profile CNC Machines.

- M30: Program end and return to start, wrapping up runs in CNC Gantry Milling Machines.

Differences Between G-Code and M-Code

| Aspect | G-Code | M-Code |

|---|---|---|

| Function | Controls tool motion (lines, arcs) | Manages auxiliary tasks (spindle, coolant) |

| Typical Commands | G00 (rapid move), G01 (linear cut) | M03 (spindle on), M30 (program end) |

| Structure | Uses coordinates/parameters (X, Y, F) | Standalone or simple parameters (S, T) |

| Modal Behavior | Mostly modal (persists until changed) | Mostly non-modal (single execution) |

| Standardization | Highly standardized (cross-machine) | Varies by brand (check manuals for CNC Routers) |

Functional Roles

- G-Code: Drives path planning for CNC Profile Machining Centers, shaping workpieces in Window & Door CNC Machines.

- M-Code: Manages logistics—e.g., activating coolant in Metal CNC Machines or pausing for adjustments in Wood CNC Machines.

Collaborative Use

G-code and M-code work in tandem, as seen in this sample program for a CNC Gantry Machining Center:

| Line | Command | Description |

|---|---|---|

| N10 | G90 G54 G17 | Set absolute positioning, work offset, XY plane |

| N20 | M03 S1200 | Start spindle (1200 RPM) for Aluminum Profile Machining |

| N30 | G01 X50 Y30 F200 | Linear cut to (X50, Y30) at 200 mm/min |

| N40 | M08 | Activate coolant (critical for Metal CNC Machines) |

| N50 | G01 X100 Y50 | Continue linear cut |

| N60 | M05 | Stop spindle |

| N70 | M09 | Deactivate coolant |

| N80 | M30 | End program, return to start |

Programming Flow

- Setup: G-codes set coordinates; M-codes start spindles/coolant (e.g., for CNC Router operations).

- Machining: G-codes direct cuts; M-codes handle pauses/tool changes (vital for Facade Fabrication CNC Machines).

- Shutdown: G-codes move tools to safety; M-codes stop spindles and end programs.

Common Pitfalls

- Sequence Errors: Ensure M03 (spindle on) precedes G01 (cutting) to avoid idle runs in CNC Vertical Machining Centers.

- Positioning: Use G28 to return to reference before M06 (tool change) in Aluminum Profile CNC Machines.

- Compatibility: Verify M-codes for proprietary CNC Machines for Windows & Doors (check manufacturer manuals).

Advanced Applications

- G-Code Cycles: G81 streamlines drilling in High-Volume Metal CNC Machine Shops.

- M-Code Macros: M98 calls subprograms for automated workflows in CNC Gantry Machining Centers.

- Debugging: Use single-block mode to validate commands—critical for precision in Laser-Enhanced CNC Routers.

Conclusion

G-code and M-code are irreplaceable in CNC programming: G-code shapes workpieces across CNC Machining Centers and Aluminum Profile CNC Machines, while M-code ensures seamless, safe operations in Wood CNC Shops and beyond. Mastering their roles—paired with knowledge of machine-specific nuances—unlocks efficiency in everything from basic milling to complex Facade Fabrication. By integrating these codes with tools like CNC Routers and Vertical Machining Centers, programmers achieve precision and reliability in every project.