Five Key Advantages of the SCA Series CNC Milling Machining

In modern manufacturing, CNC milling machining demands more than just cutting—it requires precision, power, and reliability. When you’re machining large aerospace frames, automotive transmission housings, or heavy-duty molds, you need a machine built for the toughest jobs. The SCA Series CNC Vertical Machining Center from Deli CNC delivers exactly that—combining high precision, exceptional rigidity, smart automation, system flexibility, and long-term stability to tackle complex, high-value parts across demanding industries.

Key Takeaways

- The SCA Series delivers micron-level accuracy, consistently meeting IT6 tolerance standards in CNC milling machining.

- Its double-column rigid structure minimizes vibration during heavy-duty cutting, ensuring stability and extending machine life.

- With a 2-second automatic tool changer (ATC), the SCA dramatically reduces non-cutting time and boosts throughput.

- Fully compatible with Siemens, FANUC, and other leading CNC controls—ideal for diverse CNC milling machining workflows.

- Engineered for continuous, high-load operation, the SCA maintains repeatable precision with minimal maintenance.

- Purpose-built for large structural components—not curtain wall profiles—making it perfect for aerospace, automotive, energy, and mold industries.

- Backed by Deli CNC’s global service network across Malaysia, Vietnam, the Middle East, Italy, and beyond for rapid support.

High Precision: The Foundation of Reliable CNC Milling Machining

In CNC milling machining, precision isn’t optional—it’s essential. The SCA Series achieves ±0.025 mm repeatability through a combination of finite element-optimized cast iron construction, precision-ground ball screws, and heavy-duty linear guideways. This ensures every cut, hole, and surface meets the tightest aerospace and mold-making standards.

| TECHNICAL SPECIFICATION | SCA SERIES PERFORMANCE |

|---|---|

| Positioning Accuracy | ≤ 0.04 mm |

| Repeatability | ≤ 0.025 mm |

| Spindle Speed | Up to 12,000 rpm |

| Surface Finish (Steel) | Ra 0.6–1.6 μm |

| Machining Tolerance | IT6–IT8 |

Pro Tip: The SCA’s closed-loop servo system and 0.001 mm pulse resolution enable true micro-precision—critical when machining turbine housings or injection mold cores where even minor deviations compromise performance.

Exceptional Rigidity: Built for Heavy-Duty Milling

Unlike single-column machines, the SCA’s symmetrical double-column design provides unmatched torsional rigidity—ideal for deep-pocket milling, roughing large castings, or machining high-strength alloys. This structural integrity translates directly into cleaner cuts, longer tool life, and fewer scrapped parts.

- Bed & Columns: High-density cast iron for superior vibration damping

- Spindle System: High-torque output for aggressive material removal

- Real-World Impact: One automotive supplier reduced scrap rates by 25% after switching to the SCA for transmission case machining.

Typical Applications: Aircraft structural frames, wind turbine gearbox housings, hydraulic manifolds, and large die-cast molds.

Smart Automation: Accelerating CNC Milling Machining Efficiency

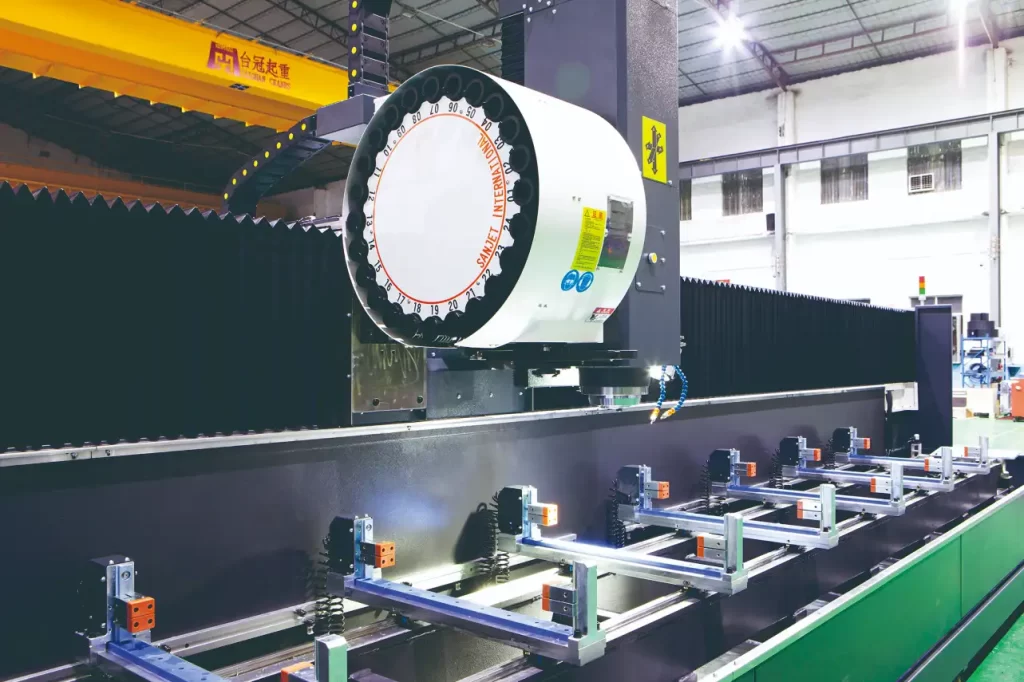

Automation isn’t just about speed—it’s about consistency. The SCA’s high-speed ATC swaps tools in just 2 seconds, enabling complex multi-operation cycles without manual intervention. Paired with optional pallet systems or robotic integration, it becomes the heart of a flexible manufacturing cell.

- Standard Tool Capacity: 24 tools (expandable to 40)

- Seamless Integration: Supports MES connectivity via OPC UA or Modbus

- Case in Point: A mold shop in East China boosted OEE from 63% to 89% by linking their SCA to a smart production scheduler.

System Compatibility: Flexibility for Evolving Needs

The SCA doesn’t lock you into one ecosystem. It supports industry-standard CNC platforms:

- Siemens: Ideal for complex 5-axis联动 (multi-axis) paths and open architecture

- FANUC: Renowned for rock-solid reliability and global service support

- Domestic Controls (e.g., Huazhong, GSK): Cost-effective for local production

Whether you’re running 2.5D contouring or full 3D surface finishing, the SCA adapts—ensuring your CNC milling machining stays agile as your business grows.

Long-Term Stability: Engineered for Uninterrupted Production

In high-volume shops, downtime is the enemy. The SCA combats it with:

- Robust Transmission System: Precision ball screws and guideways rated for 20,000+ hours

- Modular Design: Simplifies maintenance and future upgrades

- Real-Time Monitoring: Tracks spindle load, temperature, and vibration to predict issues before they cause stoppages

Global Peace of Mind: Deli CNC’s authorized distributors in Malaysia, Vietnam, Thailand, India, the Middle East, Italy, and Mexico provide local spare parts, on-site service, and multilingual support—so your SCA keeps running, wherever you are.

Industry Applications: Where the SCA Delivers Real Value

Aerospace

- Machining titanium bulkheads and aluminum wing ribs with ±0.02 mm accuracy

- Meeting AS9100 quality requirements for flight-critical components

Automotive & EV

- High-efficiency production of transmission cases, battery trays, and chassis brackets

- Supporting both ICE and new energy vehicle supply chains

Energy

- Heavy milling of wind power gearbox housings and hydraulic valve blocks

- Handling large, irregular castings with consistent surface quality

Mold & Die

- Precision finishing of large injection molds and die-cast tooling

- Achieving mirror-like surfaces (Ra ≤ 0.8 μm) in a single setup

Customer Insight: After adopting the SCA, one mold manufacturer cut delivery lead times by 30% and saw customer satisfaction jump to 92%.

Frequently Asked Questions (FAQ)

What types of CNC milling machining is the SCA best suited for?

The SCA excels at large, heavy, high-precision parts—like aerospace frames, automotive housings, and industrial molds. It is not designed for long, thin curtain wall profiles (for those, consider Deli’s MF or SP series).

How does the SCA maintain precision under heavy cutting loads? Through its double-column rigid frame, vibration-damping cast iron, and thermally stable spindle—ensuring ±0.025 mm repeatability even during extended roughing cycles.

Does a 2-second tool change really make a difference?

Yes. In multi-operation jobs, ATC can reduce non-cutting time by up to 30%, directly improving machine utilization and ROI.

Can the SCA integrate with our existing factory software?

Absolutely. It supports standard industrial protocols (OPC UA, Modbus) and works seamlessly with major MES/ERP platforms.

Is maintenance complicated?

Not at all. Modular components and remote diagnostics simplify upkeep—and Deli’s global service team is always ready to assist.