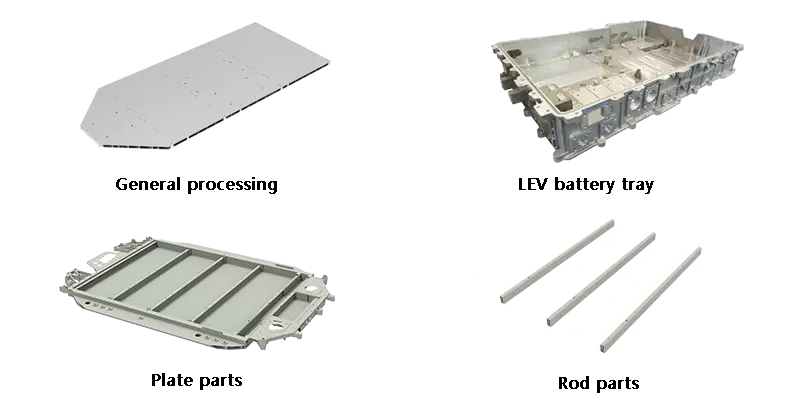

Ev Battery Trays

The worldwide automotive industry transition is in full swing. The demand for components for electric vehicles is rising continually, especially like electric motors, batteries and auxiliaries.

With insights into this trend, Deli has entered the electric vehicle manufacturing field since 2016, developing and applying a full set of new energy vehicle battery tray solutions. So far, the parts processed by Pratic Machining Centers are serving almost all major EV manufacturers around the world.

In the rapidly growing electric vehicle (EV) sector, battery trays are critical components designed to securely house and protect the battery packs.

Advantages

High-precision machining, improved efficiency

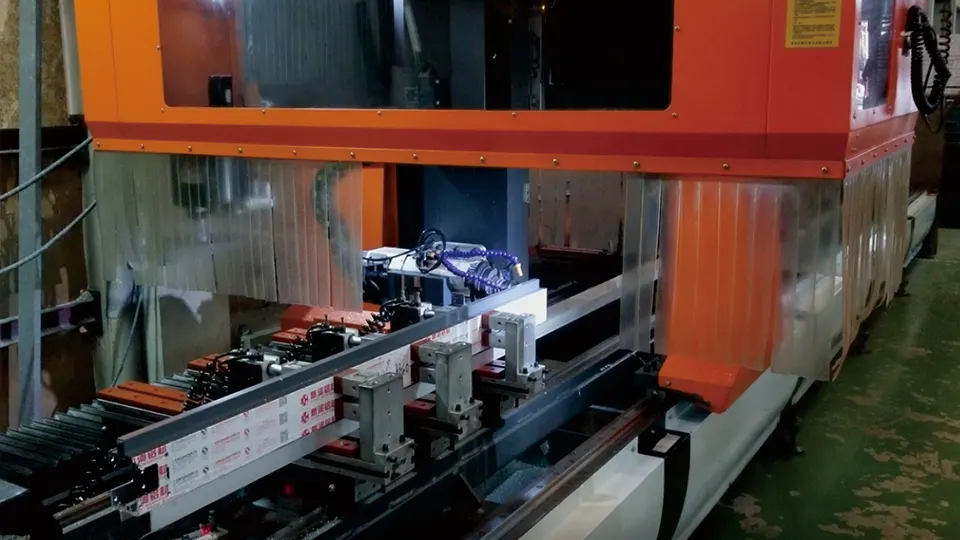

DELICNC CNC machining center adopts advanced technology to achieve micron-level precision machining, effectively improve production efficiency, reduce material waste, and provide customers with high-quality and high-stability machining solutions.

Industry-leading intelligent design

Relying on a strong R&D team, DELICNC equipment integrates intelligent automation control systems to achieve multi-axis linkage, real-time monitoring and data feedback, helping enterprises to transform into intelligent production and improve overall operational efficiency.

Wide applicability, covering the needs of multiple industries

DELICNC products are suitable for multiple high-end manufacturing fields such as automobiles, new energy vehicles, aerospace, rail transportation, 5G communications, etc., providing customized and flexible machining solutions for customers in various industries.