Curtain Walls and CNC Tools for Modern Design

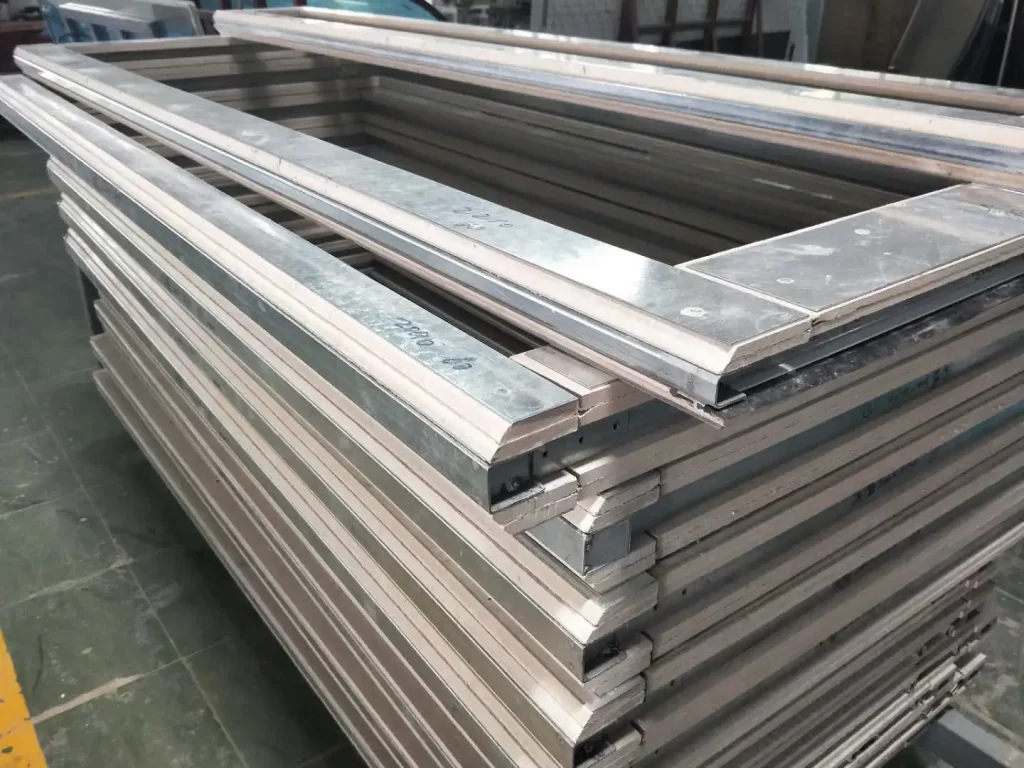

You see curtain walls shaping the look of modern buildings. They use materials like glass and aluminum to create non-structural facades that prioritize aesthetics, daylight, and energy performance. But behind every sleek facade lies a critical manufacturing challenge: precision fabrication of long, thin, hollow profiles. This is where specialized Curtain Wall CNC Fabrication Equipment—not generic machining centers—makes all the difference.

CNC technology opens doors for creative and practical solutions in today’s architecture—but only when the machine is engineered for curtain wall production.

Key Takeaways

- Curtain walls enhance modern buildings with their non-load-bearing design, enabling architectural freedom and natural light.

- Specialized CNC machines like the MF and SP series deliver micron-level precision for aluminum mullions, transoms, and brackets—unachievable with standard 3-axis routers.

- The MF650 Curtain Wall CNC offers 6.5-meter X-axis travel and 90m/min rapid speed, ideal for full-length curtain wall profiles.

- CNC automation reduces material waste by up to 30% and cuts production time by 40% compared to manual methods.

- Deli CNC provides local support in Malaysia, Vietnam, Thailand, India, Middle East, Italy, and Mexico, ensuring fast service and spare parts.

- Curtain wall CNC systems now support photovoltaic (BIPV) bracket fabrication, turning facades into power generators.

- Investing in purpose-built CNC equipment ensures ROI through faster delivery, fewer errors, and scalable production.

Curtain Walls in Modern Design

Definition and Features

Curtain walls are non-structural exterior cladding systems that hang from a building’s floor slabs or frame. They carry only their own weight and resist wind loads—but do not support the building’s structural load. This allows architects to use large glass panels, complex geometries, and lightweight materials like aluminum.

| CHARACTERISTIC | DESCRIPTION |

|---|---|

| Non-load-bearing | Enables flexible, open interior layouts and bold facades. |

| Aesthetic Appeal | Minimalist lines and transparency define iconic skyscrapers. |

| Natural Light | Maximizes daylight, reducing artificial lighting needs. |

| Energy Efficiency | High-performance glazing achieves U-values as low as 0.098. |

| Durability | Resists wind, rain, thermal expansion, and UV degradation. |

Benefits

Flexibility

Curtain walls allow endless design variations—curved forms, angled joints, custom connectors. But these require 5-axis CNC machining to produce accurately. Standard 3-axis machines cannot drill angled holes or mill thermal break channels in a single setup. The MF series Curtain Wall CNC Fabrication Equipment solves this with ±185° A-axis and ±320° C-axis rotation, enabling complex 3D features in one operation.

Efficiency

High-performance curtain walls reduce HVAC loads by up to 30%. But their value is lost if components don’t fit. CNC-fabricated parts ensure ±0.02mm tolerance, eliminating on-site adjustments. With the MF650’s 90m/min X-axis speed, a 6-meter mullion can be fully drilled, milled, and chamfered in under 8 minutes—dramatically accelerating project timelines.

Tip: Purpose-built curtain wall CNC machines like the MF or SP series integrate drilling, milling, tapping, and cutting in one setup—unlike general-purpose machining centers (e.g., SCH, SCD) designed for aerospace or molds.

Applications

Curtain walls are used in:

- Office towers (e.g., JTI Geneva HQ)

- University buildings (e.g., Kent State CAED)

- Retail facades

- High-rise residential

- Building-Integrated Photovoltaics (BIPV)

In BIPV projects, the MF and SP series CNC equipment precisely fabricate aluminum frames and mounting brackets for solar glass panels—ensuring electrical safety, structural integrity, and visual continuity.

CNC Technology Overview

What Is CNC?

CNC (Computer Numerical Control) automates machine tools via pre-programmed software. While 3-axis systems handle flat or 2.5D parts (e.g., signage, simple brackets), curtain wall fabrication demands 5-axis capability to process long profiles with multi-angle features.

Note: A standard 3-axis CNC router may cost less—but it cannot replace a curtain wall-specific CNC like the MF650 for high-volume, high-precision facade production.

CNC in Curtain Wall Manufacturing

| APPLICATION | GENERIC 3-AXISCNC | MF/SP SERIES (CURTAIN WALL CNC) |

|---|---|---|

| Profile Length | ≤2m | Up to 6.5m+ (customizable) |

| Multi-Angle Drilling | Manual repositioning required | 5-axis simultaneous machining |

| Thermal Break Milling | Not possible | Integrated in single setup |

| Production Speed | Slow, labor-intensive | 90m/min rapid traverse |

| Material Waste | High | Reduced by 30%+ |

Deli’s MF650 features:

- X/Y/Z travel: 6500 × 900 × 590 mm

- A/C-axis rotation: ±185° / ±320°

- Spindle speed: 24,000 rpm (motorized)

- Tool capacity: 8 tools, 8-second ATC

- Control system: Siemens or FANUC

This enables full automation of mullions, pressure plates, and connector slots—critical for unitized curtain wall systems.

Curtain Wall CNC Fabrication

Precision and Quality

The rigid cast-iron frame of the MF series minimizes vibration during high-speed cutting, ensuring surface finish and dimensional accuracy. Every hole, slot, and chamfer is machined to ±0.02mm tolerance, guaranteeing perfect fit during installation.

Speed and Scalability

With simultaneous 5-axis linkage and fast ATC, the MF650 processes complex profiles without manual intervention. This allows curtain wall fabricators to:

- Scale from prototypes to mass production

- Handle tight deadlines for high-rise projects

- Reduce labor dependency

Material Options

Curtain wall CNC machines process:

- Aluminum alloys (6063, 6061)

- Steel and stainless steel

- ACM / Alucobond panels

- Photovoltaic bracket materials

- Composite and thermal break profiles

Key Advantage: Unlike general CNC centers, the MF and SP series are optimized for long, hollow, thin-walled profiles—preventing deformation during clamping and cutting.

Design Innovation

Complex Shapes

Architects now design facades with double-curved surfaces, diagrid patterns, and parametric geometries. Only 5-axis curtain wall CNC machines can produce these reliably. The MF650’s Siemens control system supports direct import from Revit, Tekla, or CAD/CAM software—enabling seamless digital workflow from BIM to fabrication.

Customization

Every project is unique. Deli’s SP series offers cost-effective CNC solutions for standard curtain wall and window production, while the MF series handles bespoke, high-complexity facades. Both support custom lengths and multi-material processing.

Installation and Maintenance

CNC-fabricated components reduce on-site labor by up to 40%. With perfect-fit parts, installers spend less time adjusting and more time assembling.

Regular maintenance—supported by Deli’s global service network—ensures long-term performance:

- Local distributors in 7+ countries

- On-site training at China HQ or remote video support

- Multi-language assistance (English, Chinese, Arabic, Spanish)

- Fast spare parts delivery

Choosing the Right CNC Equipment

Not all CNC machines are equal for curtain walls.

| MACHINE TYPE | BEST FOR | DELI MODEL |

|---|---|---|

| Curtain Wall CNC | Aluminum mullions, BIPV brackets, complex profiles | MF650 |

| Door & Window CNC | Standard windows, storefronts, batch production | SP Series |

| Double-Head Saw | 45°/90°/compound angle cutting | LP-900A-650, LP-F900 |

| General Machining Center | Aerospace, molds, short parts | SCH, SCD, HA (not ideal for curtain walls) |

Recommendation: For curtain wall manufacturers, invest in purpose-built equipment—not repurposed industrial CNCs.

Future of Curtain Walls and CNC

Emerging Tech

- Smart Glass + CNC Frames: Precise machining enables integration of electrochromic or PV glass.

- Digital Twins: CNC machines feed real-time data to BIM models for quality control.

- Robotic Integration: LP saws and MF centers link with robotic arms for fully automated lines.

Sustainability

CNC-fabricated curtain walls support green building goals by:

- Minimizing material waste

- Enabling high-performance thermal breaks

- Supporting recyclable aluminum systems

- Integrating renewable energy (BIPV)

FAQ

What is Curtain Wall CNC Fabrication Equipment?

It’s a specialized CNC machine (like Deli’s MF or SP series) designed exclusively for drilling, milling, and cutting long aluminum profiles used in curtain walls—not general-purpose machining centers.

Can your CNC machines process thermal break aluminum without deformation?

Yes. The MF series uses low-vibration spindles, rigid frames, and optimized clamping to prevent profile bending—critical for thermal break integrity.

How does the MF650 compare to a standard 3-axis CNC router?

A 3-axis router cannot machine angled holes or 3D features in one setup. The MF650’s 5-axis linkage (A: ±185°, C: ±320°) enables full automation of complex curtain wall components—reducing cycle time by 50%+.

Do you offer on-site training for overseas customers?

Yes. We provide:

- On-site training at our China factory

- Remote video guidance

- Local support via distributors in Malaysia, Vietnam, Thailand, India, Middle East, Italy, and Mexico

Can your CNC equipment fabricate parts for solar curtain walls (BIPV)?

Absolutely. The MF and SP series are widely used to produce aluminum frames and mounting brackets for building-integrated photovoltaic systems—ensuring precision, safety, and aesthetic alignment.

What’s the ROI of investing in curtain wall CNC equipment?

Most customers see ROI within 12–18 months through:

- 30% less material waste

- 40% faster production

- Reduced labor and rework costs

- Ability to bid on high-value, complex projects

Curtain walls and CNC tools deliver precision, efficiency, and custom design for modern buildings, enhancing aesthetics, energy savings, and sustainability.