Coolant Selection in CNC Machining: Maximize Tool Life & Finish

In precision manufacturing, the selection of an appropriate coolant type directly influences machining efficiency, tool longevity, and dimensional accuracy of finished components. The four principal categories — straight oils, soluble oils, semi-synthetic fluids, and fully synthetic formulations — exhibit distinct performance profiles in lubrication, heat dissipation, material compatibility, and environmental impact. This guide provides a systematic analysis of their chemical composition, functional characteristics, and application-specific selection criteria, enabling engineers to optimize machining performance while maintaining operational safety and regulatory compliance.

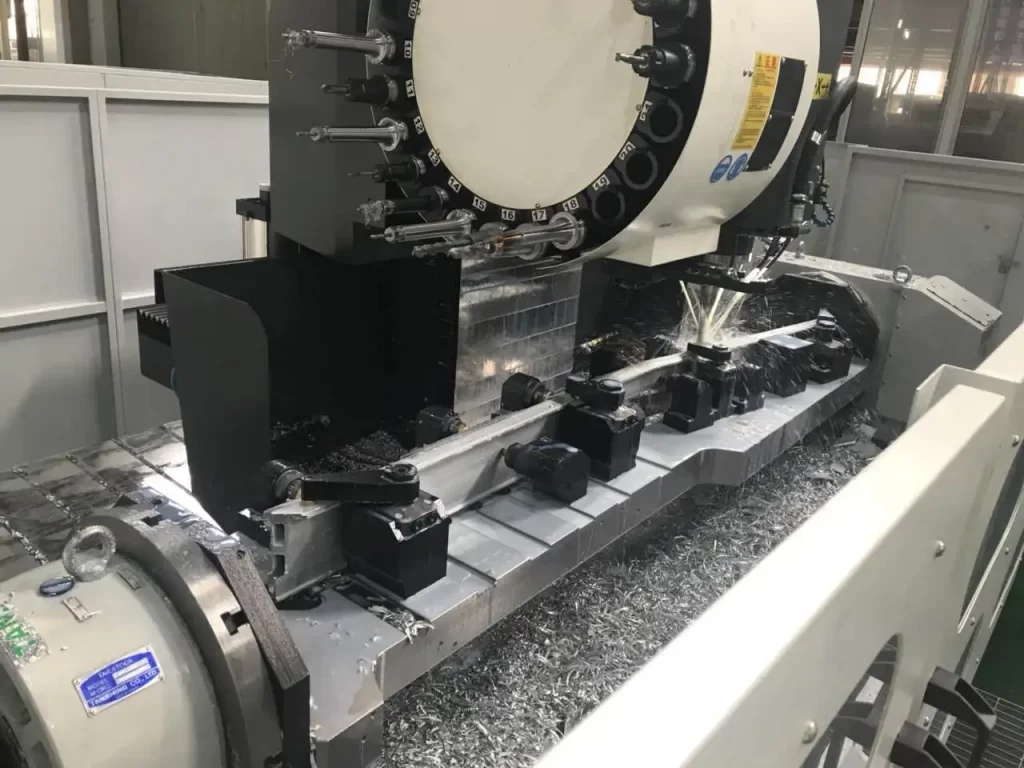

1. The Functional Role of Coolants in CNC Machining

1.1 Core Operational Functions

Regardless of formulation, all industrial coolants serve five fundamental purposes: thermal regulation, friction reduction, chip evacuation, corrosion inhibition, and surface integrity preservation. Empirical data indicate that appropriate coolant selection can extend tool life by a factor of three and reduce thermal distortion in machined components by 50%. In high-speed or difficult-to-machine material applications, coolant compatibility is often the determining factor in process viability.

- Thermal Regulation: Cutting zone temperatures may exceed 1000°C. Coolants mitigate thermal degradation of cutting edges through convective heat transfer.

- Friction Reduction: Extreme-pressure (EP) and boundary lubrication additives form protective tribofilms at the tool-workpiece interface, minimizing adhesive wear and built-up edge formation.

- Chip Evacuation: Directed coolant flow prevents chip re-cutting and entanglement, ensuring consistent operation of the CNC machine coolant delivery system.

- Corrosion Inhibition: Controlled pH and corrosion inhibitors protect machine components, fixtures, and workpieces — particularly critical when coolant pH deviates from optimal range.

- Surface Integrity: Stable thermal conditions reduce residual stresses and improve surface finish consistency.

1.2 Consequences of Inappropriate Coolant Selection

Failure to match coolant properties to material and process requirements may result in:

- Accelerated tool wear, edge chipping, or premature failure;

- Thermal damage, metallurgical alteration, or dimensional instability in workpieces;

- Blockage of coolant distribution lines, pump cavitation, or cross-contamination of lubrication systems;

- Occupational health hazards, including dermatological reactions, respiratory exposure to coolant mist, or sensitization risks;

- Non-compliance with environmental regulations, including elevated COD in effluent, VOC emissions, or costly coolant waste disposal procedures.

2. Classification and Characteristics of the Four Primary Coolant Types

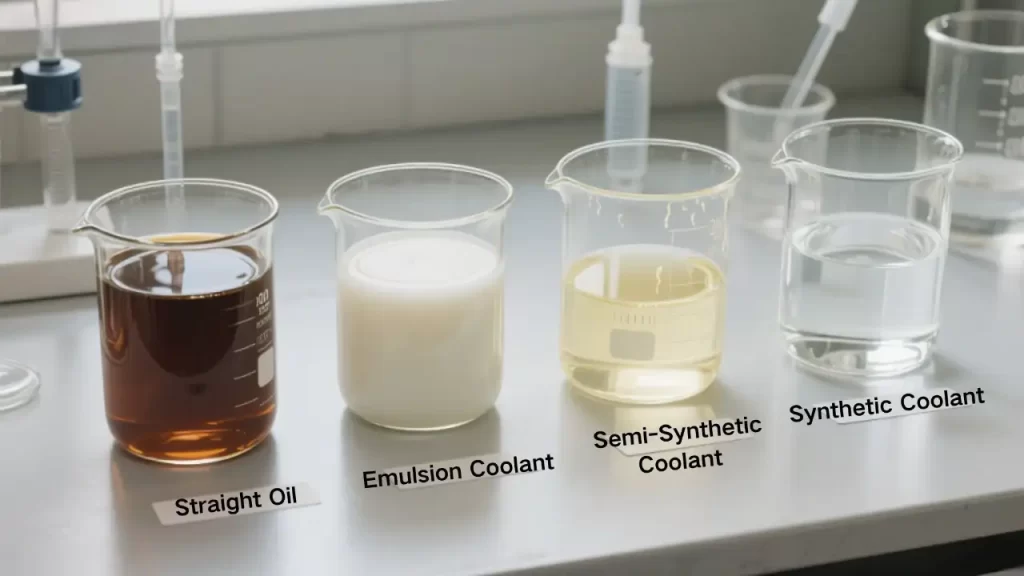

2.1 Straight Oils (Neat Oils)

Formulated from mineral or synthetic base oils, straight oils deliver superior lubrication under high-load conditions. Among industrial coolant categories, they provide the highest extreme-pressure performance but exhibit the lowest thermal conductivity and poorest environmental profile. Commonly employed in gear hobbing, broaching, and deep-hole drilling of titanium alloys.

Recommended Applications: Deep-hole drilling, broaching, machining of nickel-based superalloys.

Operational Considerations: Flammable; requires thorough post-process cleaning; low biodegradability necessitates integration with a coolant recycling system to minimize waste generation.

2.2 Soluble Oils (Emulsifiable Coolants)

The most widely adopted coolant category due to cost efficiency and broad process compatibility. Soluble oils offer balanced lubrication and cooling performance but are highly sensitive to water quality and microbial proliferation. Predominantly used in general turning and cast iron machining operations.

Recommended Applications: General turning, milling, drilling of ferrous alloys .

Operational Considerations: Susceptible to microbial contamination; requires periodic addition of biocidal agents; excessive foaming may indicate water hardness incompatibility.

2.3 Semi-Synthetic Coolants

Engineered as a hybrid between emulsifiable oils and full synthetics, semi-synthetic formulations combine enhanced lubricity with improved resistance to microbial degradation and foam stability. Increasingly specified for high-speed machining of stainless steels and aluminum alloys.

Recommended Applications: High-speed milling, multi-axis machining centers

Operational Considerations: Sensitive to water chemistry; coolant concentration should be monitored regularly using a calibrated refractometer.

2.4 Fully Synthetic Coolants

Representing the evolution toward high-performance, environmentally responsible formulations, fully synthetic coolants contain no mineral oil. Their clarity, low residue, and filtration compatibility make them ideal for precision grinding and automated production environments. Lubricity limitations in heavy-duty applications have been largely mitigated through advanced additive technology.

Recommended Applications: Precision surface and cylindrical grinding, cleanroom manufacturing, automated production lines Operational Considerations: May induce corrosion in copper or aluminum alloys; chlorine-free or boron-free formulations are recommended for sensitive materials.

3. Material-Specific Coolant Selection Guidelines

3.1 Ferrous Alloys (Carbon Steel, Alloy Steel, Cast Iron)

Semi-synthetic formulations containing borate-amine corrosion inhibitors (target pH 8.5–9.5) or high-oil-content emulsions (>40% oil phase) are recommended. Critical parameters include:

- Avoid chlorine-containing EP additives to prevent stress corrosion cracking in austenitic stainless grades;

- Use low-foaming formulations for cast iron to prevent graphite-induced filter clogging;

- For deep-hole drilling in alloy steels, select fluids with four-ball weld load exceeding 800 N.

3.2 Stainless Steels and Heat-Resistant Alloys (e.g., Inconel, Hastelloy)

Require sulfur-based EP additives in semi-synthetic or straight oil formulations. Operational parameters:

- Maintain cutting zone temperature below 350°C;

- Use concentrations of 8–12% to ensure boundary film integrity;

- Avoid copper-based corrosion inhibitors to prevent intergranular attack in nickel alloys;

- Prefer chlorine-free formulations to mitigate health and environmental exposure risks.

3.3 Aluminum and Its Alloys

Select weakly alkaline fully synthetic coolants (pH 7.5–8.5) or dedicated aluminum-compatible formulations. Avoid:

- Sodium silicate-based additives, which cause surface staining;

- Nitrite-containing inhibitors, which promote pitting corrosion;

- Post-process immediately with 5% nitric acid passivation or utilize a dedicated parts cleaning system.

3.4 Titanium Alloys

Mandatory use of chlorine-free coolants or titanium-specific formulations. Operational constraints:

- Chloride ion concentration <50 ppm; sulfur content <0.1%;

- Employ high-pressure through-tool delivery (≥7 MPa, flow rate >10 L/min);

- Avoid dry machining to prevent hydrogen embrittlement.

3.5 Copper and Copper Alloys

Utilize neutral-pH (7.0–8.0) fully synthetic coolants containing 0.05–0.1% benzotriazole (BTA). Additional considerations:

- Control free acidity during brass machining;

- Use low-viscosity formulations for pure copper turning;

- Avoid shared coolant systems with aluminum components to prevent galvanic corrosion.

3.6 Composite Materials (CFRP, GFRP)

Minimum Quantity Lubrication (MQL) or dry machining is preferred. If coolant is required:

- Use non-ionic surfactant-based water-miscible fluids;

- Limit delivery pressure to <0.5 MPa to prevent delamination;

- Perform immediate post-process cleaning with isopropyl alcohol or engage professional coolant system cleaning services.

4. Process- and Equipment-Driven Coolant Selection

4.1 Turning and Milling Operations

Semi-synthetic coolants at 5–7% concentration are suitable for the majority of applications. For high-speed milling (cutting speed >500 m/min), low-viscosity fully synthetic coolants with optimized nozzle atomization are recommended.

4.2 Grinding Processes

Require low-foaming fully synthetic formulations (0.1–0.3% antifoam agent) in conjunction with fine-filtration systems (filter rating <10 μm). For wheel speeds exceeding 50 m/s, maintain coolant flow rate ≥5 L/min per kW of grinding power.

4.3 Deep-Hole and Gun Drilling

High-viscosity straight oils (ISO VG 32–46) or EP-enhanced semi-synthetics (>8% EP additive) under high pressure (7–20 MPa) are required to ensure chip evacuation velocity >1.5 m/s. Regular inspection of coolant manifolds and delivery hoses is essential.

4.4 High-Speed Machining (HSM)

Fully synthetic coolants with kinematic viscosity <10 cSt at 40°C, paired with MQL-compatible delivery systems (air pressure 0.4–0.6 MPa, oil flow 5–50 mL/h), are optimal. This configuration maintains cutting temperatures below 200°C and minimizes coolant mist generation.

4.5 Multi-Axis and Five-Axis Machining Centers

Transparent fully synthetic coolants (turbidity <10 NTU, residual film <0.1 g/m²) prevent contamination of optical encoders and capacitive sensors. Integration of real-time concentration monitoring systems (accuracy ±0.2%) is recommended.

4.6 Automated and Unmanned Production Systems

Long-life synthetic formulations with controlled-release biocides, compatible with centralized filtration (1 μm rating) and automated concentration control (±0.5% tolerance), can extend fluid service life to 12 months. Implementation of a coolant recycling system reduces waste volume and disposal costs.

5. Performance Evaluation Metrics for Industrial Coolants

| Parameter | Test Method | Acceptable Threshold | Measurement Instrument |

|---|---|---|---|

| Lubricity | ASTM D2783 (Four-Ball) | Weld load >600 N; scar <0.7 mm | Four-ball wear tester |

| Cooling Efficiency | DIN 51811 | ΔT/Δt >15°C/s (from 100°C) | Thermocouple + data logger |

| Corrosion Protection | ASTM D4627 (Cast Iron) | No rust at 48 h; <10% at 96 h | Humidity cabinet |

| Microbial Stability | ISO 14644 (Plate Count) | <10⁴ CFU/mL | Microbial culture plating |

| Foam Characteristics | GB/T 7462 (Ross-Miles) | Foam height <50 mm; collapse <30 s | Foam stability tester |

| Concentration Control | Refractometry / Titration | Tolerance ±0.5% | Digital refractometer |

| pH Stability | Potentiometric | 8.0–9.5 | Calibrated pH meter |

Maintain daily logs of coolant concentration, weekly pH measurements, and monthly microbial assays to ensure consistent performance.

6. Coolant System Maintenance and Operational Best Practices

6.1 Concentration Management

Monitor concentration daily using a calibrated refractometer or titration method. Adjust if deviation exceeds ±1%. Recommended operating ranges:

- Soluble oils: 3–5% (carbon steel), 5–8% (stainless steel)

- Semi-synthetics: 5–7% (general purpose), 8–10% (heavy-duty)

- Fully synthetics: 3–5% (grinding), 5–8% (high-speed machining)

Display a coolant concentration reference chart in the machining area for operator guidance.

6.2 Water Quality Control

Target water specifications: hardness <100 ppm (as CaCO₃), chloride <50 ppm, conductivity <500 μS/cm. Installation of reverse osmosis (RO) pretreatment is recommended to prevent foam instability and emulsion breakdown.

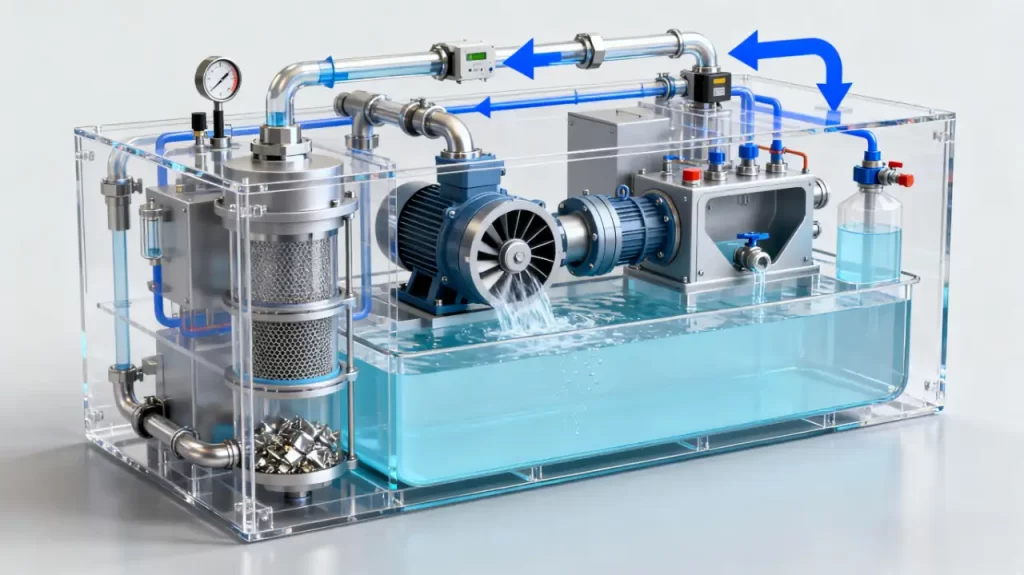

6.3 Filtration and Contaminant Removal

Implement a three-stage filtration system:

- Magnetic separator (>90% ferrous particle removal)

- Disposable media filter (20–50 μm rating)

- Centrifugal or coalescing purifier (tramp oil and submicron contaminant removal)

Replace filtration elements per manufacturer schedule to prevent line blockage.

6.4 Microbial Control Protocol

- Add 0.1–0.3% biocide weekly;

- Maintain dissolved oxygen >4 mg/L via aeration;

- Control sump temperature between 20–35°C; avoid direct sunlight exposure;

- Initiate system cleaning protocol upon detection of odor or visible biofilm.

6.5 Waste Coolant Management

Compliant disposal procedure:

- Adjust pH to 6–9 using sulfuric acid or sodium hydroxide;

- Apply demulsifying agents to separate free oil (recovery efficiency >95%);

- Use flocculation to reduce suspended solids (target <50 mg/L);

- Transfer waste to licensed hazardous waste handlers (EPA Waste Code HW09).

Integration of a closed-loop coolant recycling system supports resource conservation and reduces long-term operational costs.

7. Emerging Coolant Technologies and Alternative Machining Strategies

7.1 Minimum Quantity Lubrication (MQL)

Utilizes vegetable-based esters at flow rates of 5–50 mL/h, reducing fluid consumption by up to 95% and lowering cutting forces by 10–15%. Requires modification of internal coolant channels; unsuitable for materials generating water-soluble chips. Significantly reduces operator exposure to coolant mist.

7.2 Cryogenic Cooling

Liquid nitrogen (–196°C) or CO₂ snow (–78°C) applied at the cutting interface can reduce titanium alloy machining temperatures to –50°C, extending tool life by a factor of four. Energy consumption averages 3–5 kWh per component. Eliminates conventional coolant use entirely.

7.3 Dry Machining

Relies on advanced tool coatings (e.g., TiAlN, AlCrN) combined with chilled air systems (–30°C). Suitable for gray cast iron and select aluminum alloys. Reduces energy consumption by approximately 30%, though tooling costs increase by 50%. Eliminates post-process coolant cleaning requirements.

7.4 Intelligent Coolant Management Systems

Integrate real-time sensors for pH, concentration, and temperature with predictive algorithms to forecast fluid replacement intervals (accuracy <5%). Implementation in automotive production environments has demonstrated 22% reduction in coolant-related costs and 40% decrease in waste volume.

7.5 Bio-Based Coolant Formulations

Derived from renewable feedstocks such as palm methyl esters or polylactic acid, these fluids exhibit biodegradability exceeding 90% and dermal LD50 values >2000 mg/kg. Lubricity remains slightly inferior to mineral oil-based products but aligns with regulatory trends favoring chlorine-free and boron-free industrial fluids.

8. A Systematic Coolant Selection Framework for CNC Applications

- Identify Workpiece Material → Select material-compatible coolant category (e.g., titanium → chlorine-free formulation)

- Define Machining Parameters → Prioritize lubrication (high load) or cooling (high speed)

- Assess Machine Capabilities → High-pressure internal delivery → straight oil; automated lines → long-life synthetic + recycling system

- Review Regulatory Requirements → EU REACH compliance → VOC <50 g/L; medical components → nitrosamine-free, low-sensitization risk

- Evaluate Total Cost of Ownership → Include fluid cost, change frequency, waste disposal, and tool wear impact

- Conduct Trial Machining → Validate tool life, surface roughness, and dimensional stability under production conditions

- Document Standard Operating Procedures → Define monitoring frequency for concentration and pH, sump cleaning intervals, and corrective action protocols

9. Frequently Asked Questions: Technical Clarifications and Troubleshooting Guidance

Q1: What causes dark surface staining on machined aluminum components?

A: Typically results from silicate-containing coolants or elevated pH levels. Use aluminum-specific or boron-free formulations. Implement immediate post-process passivation with 5% nitric acid or utilize a dedicated cleaning system.

Q2: How should microbial contamination and odor development be addressed?

A: Enhance filtration efficiency, administer biocides at recommended intervals, maintain target concentration, and eliminate tramp oil ingress. In cases of severe contamination, perform a complete system flush or engage professional cleaning services.

Q3: Are fully synthetic coolants inherently non-irritating to skin?

A: Not necessarily. Review Safety Data Sheets (SDS) for skin irritation classification. Prefer formulations free of alkanolamines and nitrosating agents to minimize dermatological risk and potential carcinogen formation.

Q4: Is it permissible to mix coolants of different types or brands?

A: Mixing is not recommended. Incompatible formulations may cause phase separation, additive precipitation, or performance degradation. A complete system cleaning procedure — including sump, distribution lines, and hoses — is required prior to fluid changeover.

Q5: Does higher coolant concentration improve machining performance?

A: Not universally. Excessive concentration may induce foaming, increase residue, and elevate operational costs. Insufficient concentration compromises lubrication and corrosion protection. Adhere to manufacturer-recommended dilution ratios, verified using a calibrated refractometer.

Conclusion

The strategic selection and disciplined management of industrial coolants constitute a critical determinant of machining performance, operational safety, and environmental compliance in CNC manufacturing. From filtration system design to recycling infrastructure, from concentration control to microbial monitoring, each element contributes to process reliability and resource efficiency. A scientifically grounded approach to coolant management enables sustained improvements in productivity, tool life, workplace safety, and ecological responsibility — delivering measurable value across the manufacturing lifecycle.