CNC Turning Vs. Grinding: Precision and Efficiency Comparison

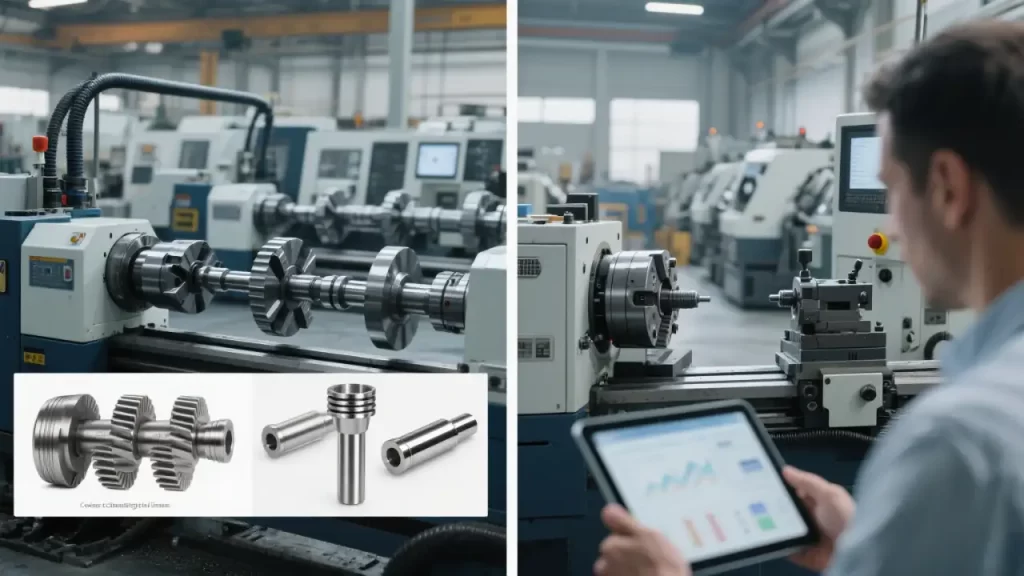

In modern precision manufacturing, CNC turning and grinding are essential machining processes, widely used in CNC turning services and CNC grinding equipment. Each offers unique strengths in machining precision, efficiency, and applications, making it vital to understand the differences between CNC turning and grinding to optimize processes, improve CNC turned parts quality, and reduce costs.

This article explores the principles, equipment, material compatibility, precision, efficiency, applications, advantages, limitations, and combined strategies of CNC turning and grinding, guiding professionals to select the best CNC turning services or CNC grinding machines for high-efficiency, high-precision production.

1. CNC Turning: High-Efficiency Machining

1.1 Principles and Mechanics

CNC turning is a subtractive process that shapes a rotating workpiece with a cutting tool following a programmed path to create CNC turned parts. Controlled by a CNC system, the CNC turning process manages spindle speed, feed rate, and tool trajectory via G-code for automated machining. Ideal for cylindrical components like shafts, sleeves, and threaded parts, CNC turning is central to CNC turning services. Precision CNC turning, often performed in CNC turning centers, excels in efficiency and versatility.

Moreover, this method allows for consistent repeatability and tight dimensional control, especially when integrated with advanced tool monitoring systems. As a result, it has become a cornerstone in high-volume production environments.

1.2 Types of Equipment

CNC turning equipment includes:

- Horizontal CNC Lathes: With a horizontal spindle, these excel at machining long, shaft-like CNC turned parts, offering stable clamping and efficient chip removal, a mainstay of CNC turning services.

- Vertical CNC Lathes: Featuring a vertical spindle, they handle large-diameter parts like flanges, enhancing CNC turning efficiency.

- CNC Turning Centers: Equipped with live tooling, these support CNC milling and turning, performing turning, milling, drilling, and tapping in one setup.

- Multi-Axis CNC Lathes (e.g., Swiss-type): Designed for precision CNC turning, they produce slender, high-precision parts like medical needles with machining precision up to ±0.005mm.

These machines vary in configuration but share the goal of maximizing productivity and minimizing setup time.

1.3 Tools and Material Compatibility

CNC turning uses indexable inserts made of:

- Carbide: Versatile and durable, ideal for steel, stainless steel, and cast iron in CNC turning services.

- Ceramic: Suited for high-speed machining of hardened steel and superalloys.

- Cubic Boron Nitride (CBN): Near-diamond hardness, perfect for hardened steel (>45HRC).

- Polycrystalline Diamond (PCD): Ideal for non-ferrous metals (e.g., aluminum, copper) and composites, ensuring long tool life and excellent surface finish.

CNC turning handles a wide range of materials, including:

- Metals: Carbon steel, stainless steel, aluminum, titanium, and nickel-based superalloys.

- Non-metals: Engineering plastics (e.g., PEEK, nylon), composites, and ceramic preforms.

CNC turning services require tailored tool materials, coatings, and parameters. For example, stainless steel, prone to built-up edge, needs TiAlN-coated tools and robust cooling, while titanium alloys demand low-speed, high-depth cuts to avoid overheating. In addition, proper selection of cutting fluids and chip breakers further enhances process stability.

1.4 Key Applications

CNC turning and CNC turning centers are widely used in:

- Automotive Industry: Producing crankshafts, wheel hubs, and other CNC turned components.

- Aerospace: Crafting rotor shafts and hydraulic fittings with precision CNC turning.

- Medical Devices: Manufacturing bone screws and syringe tubes as high-precision CNC turned parts.

- Energy Sector: Creating valve bodies and pump shafts via CNC turning services.

These applications benefit significantly from the speed and flexibility offered by modern CNC turning technology.

2. Grinding: Precision Finishing Expert

2.1 Principles and Mechanics

Grinding employs a high-speed rotating wheel with abrasive grains to remove minute material amounts, achieving superior machining precision and surface finish. CNC grinding machines control wheel feed, speed, and dressing via programming, ensuring consistent grinding processes. Unlike the rapid shaping of CNC turning, grinding excels in finishing, with low material removal rates but exceptional accuracy.

Furthermore, due to its ability to achieve sub-micron tolerances, grinding is often the final step in critical component manufacturing. This makes it indispensable in industries where surface integrity and dimensional accuracy are paramount.

2.2 Types of Grinding

Grinding processes include:

- External Cylindrical Grinding: Shapes shaft exteriors with precision up to IT5 and Ra≤0.1μm, often using CNC cylindrical grinding machines.

- Internal Grinding: For precision bores, such as bearing races.

- Surface Grinding: For flat surfaces or steps, common in CNC surface grinding machines.

- Centerless Grinding: Ideal for high-volume small-diameter rods, like piston pins.

- Form Grinding: Shapes complex contours, such as gear teeth.

Each type serves specific geometries and tolerance requirements, allowing manufacturers to match the process to the part’s functional needs.

2.3 Equipment and Wheel Selection

CNC grinding equipment includes CNC cylindrical grinding machines, CNC surface grinding machines, and five-axis grinders. Wheel selection depends on material and precision needs:

| MATERIAL | RECOMMENDED WHEEL TYPE |

|---|---|

| Hardened/Tool Steel | CBN Wheel |

| Carbide | Diamond Wheel |

| Mild Steel | White Alumina (Al₂O₃) |

| Cast Iron | Green Silicon Carbide |

| Aluminum Alloy | Loose-Structure Alumina |

Grinding processes require periodic wheel dressing to maintain sharpness and geometry, typically using diamond rollers or pens. Consequently, maintenance and operational expertise play a crucial role in sustaining consistent output quality.

2.4 Key Applications

CNC grinding equipment serves:

- Bearing Manufacturing: Grinding raceways with tolerances of ±1μm and Ra<0.05μm.

- Tool Manufacturing: Sharpening cutting edges with CNC grinding machines.

- Aerospace: Finishing turbine blade dovetails.

- Mold Industry: Precision grinding of mold cavities using CNC surface grinding machines.

These sectors rely heavily on grinding to meet stringent surface and geometric specifications.

3. Key Differences Between CNC Turning and Grinding

| PARAMETER | CNC TURNING | GRINDING |

|---|---|---|

| Process | Cutting | Abrasion |

| Motion | Workpiece rotates, tool feeds | Wheel rotates, workpiece may/may not |

| Material Removal Rate | High (hundreds mm³/min) | Low (<50mm³/min) |

| Machining Precision | ±0.01mm (IT6~IT7) | ±0.001mm (IT4~IT5) |

| Surface Finish (Ra) | 0.8~3.2 μm | 0.1~0.4 μm, mirror at 0.025μm |

| Material Suitability | Broad range | Hard materials (>45HRC) |

| Efficiency | Fast | Slow |

| Equipment Cost | Moderate | High |

| Typical Parts | Shafts, bolts, flanges | Bearings, tools, molds |

This comparison clearly highlights the complementary nature of both processes.

4. In-Depth Analysis of Advantages and Limitations

Advantages of CNC Turning:

- High efficiency for mass production of CNC turned components.

- CNC turning centers integrate CNC milling and turning capabilities.

- Cost-effective equipment and tools.

- Broad material compatibility.

Additionally, CNC turning offers shorter cycle times and reduced labor costs, making it ideal for high-throughput operations.

Limitations of CNC Turning:

- Surface finish struggles to reach Ra<0.8μm.

- Machining precision affected by tool wear and vibration.

- Unsuitable for ultra-hard materials (>55HRC).

Therefore, while CNC turning is highly efficient, it may not suffice for final finishing of hardened or high-tolerance parts.

Advantages of Grinding:

- Exceptional machining precision with tolerances within ±1μm.

- Superior surface finish, down to Ra 0.025μm.

- Ideal for hard materials, leveraging CNC grinding machines.

As a result, grinding remains the go-to solution for achieving mirror finishes and micron-level accuracy.

Limitations of Grinding:

- Low material removal rate, unfit for roughing.

- High costs for CNC grinding equipment and wheels.

- Complex process requiring frequent wheel dressing.

Despite its precision, grinding demands skilled operators and careful process planning to remain cost-effective.

5. Choosing Between CNC Turning and Grinding

The differences between CNC turning and grinding guide process selection:

- Machining Precision: Tolerances >±0.01mm favor CNC turning services; ≤±0.005mm require grinding.

- Material Hardness: HRC<45 suits **precision CNC turning**; >45 needs CNC cylindrical grinding machines.

- Batch Size: Large batches align with CNC turning centers; small, high-value parts suit CNC grinding equipment.

- Machining Stage: Roughing uses CNC turning, finishing uses grinding.

Hence, understanding the part’s functional requirements is essential before deciding on the optimal process.

6. Combined Strategy: CNC Turning + Grinding

CNC turning and grinding complement each other: rough turning → semi-finishing → heat treatment → finish grinding.

For example, automotive crankshafts are shaped via CNC turning services, then finished with CNC cylindrical grinding machines to ensure precision and surface finish. Combining CNC milling and turning with CNC surface grinding machines enhances complex part quality.

In fact, hybrid manufacturing approaches often yield the best balance between productivity and precision.

7. Conclusion: Balancing Efficiency and Precision

CNC turning excels in efficiency, while grinding delivers unmatched machining precision. The differences between CNC turning and grinding hinge on balancing speed and accuracy. Combining CNC turning services with CNC grinding equipment is ideal for high-end manufacturing. Before production, collaborate with engineers to select optimal CNC turning centers or CNC surface grinding machines and refine programs to produce top-quality CNC turned parts.

Ultimately, the choice depends on the specific application, material, and desired outcome. Do you lean toward precision CNC turning or CNC grinding machines for your projects? Share your thoughts in the comments!