CNC Machining Equipment: Boosting Efficiency in Complex Part Production

Complex surface parts, such as turbine blades and automotive molds, pose significant challenges for CNC machining equipment due to their non-planar geometries and stringent precision requirements. This guide provides a detailed roadmap for leveraging CNC machining centers to achieve high-efficiency production of such parts, covering part characteristics, advantages of high-precision CNC equipment, optimization of CNC machining techniques, tool selection, fixture design, quality control, real-world case studies, and practical efficiency-enhancing tips. It is tailored for industries like aerospace precision machining, automotive manufacturing CNC machines, new energy vehicle part machining, rail transit part machining equipment, and 5G equipment manufacturing machines.

1. Characteristics and Challenges of Complex Surface Parts

1.1 Characteristics of Complex Surface Parts

Complex surface parts, such as aerospace turbine blades or new energy vehicle components, exhibit the following traits:

- Non-linear Geometry: Surfaces with continuously varying curvature require multi-angle cutting.

- High Precision Requirements: Dimensional tolerances are often in the micrometer range, with surface finishes as fine as Ra 0.2–0.3 μm, meeting aerospace precision machining standards.

- Material Diversity: Aluminum alloys are prone to sticking, titanium alloys are hard (common in 5G equipment manufacturing machines), and stainless steel generates significant machining stress.

1.2 Machining Challenges

- Complex Tool Paths: Intricate surface geometries demand sophisticated tool trajectories, where poor planning can lead to inefficiencies or defects.

- Multiple Clamping: Traditional three-axis CNC machines require multiple setups, increasing errors and time costs.

- Material Adaptability: Different material properties necessitate precise parameter adjustments, requiring tailored solutions from CNC machining center suppliers.

- Surface Quality: Tool marks or rough surfaces can compromise performance, necessitating advanced CNC machining techniques.

1.3 Strategies to Address Challenges

- Define Geometric Requirements: Analyze surface features to generate optimized tool paths.

- Select High-Precision CNC Equipment: Prioritize multi-axis CNC machining centers to minimize clamping.

- Optimize Material Compatibility: Adjust tools and cutting parameters to suit material properties, aligning with industrial CNC machining equipment needs.

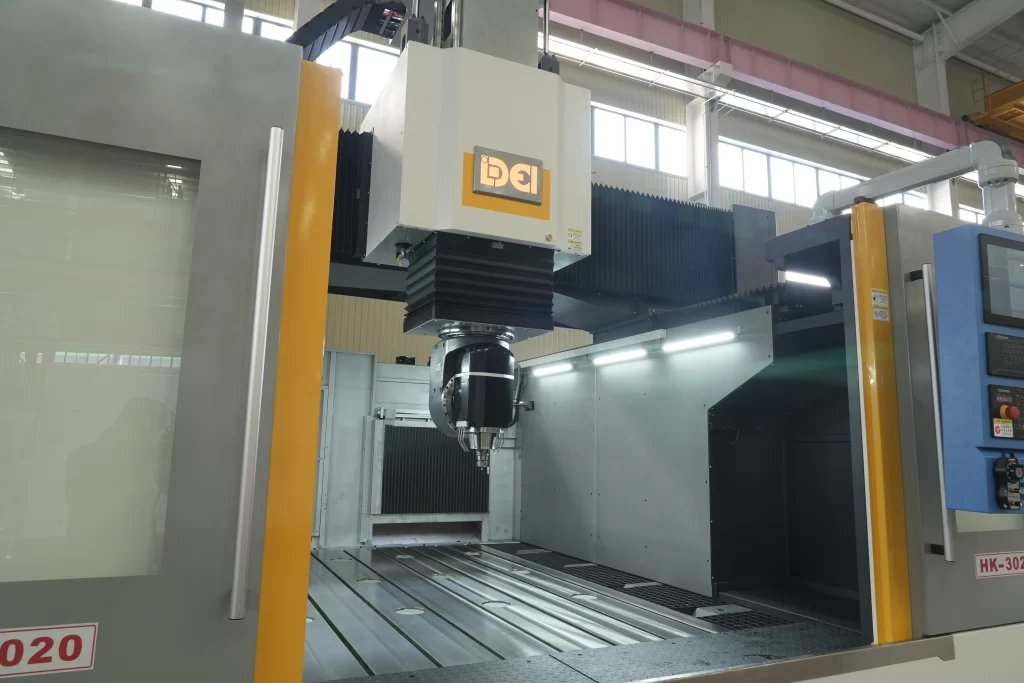

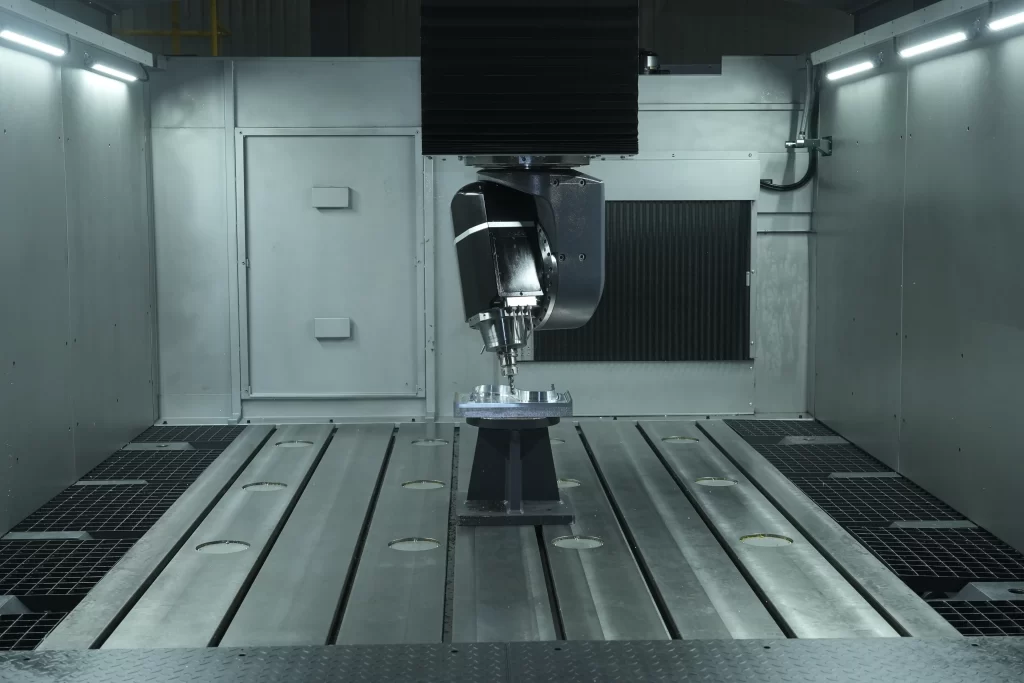

2. Core Advantages of Multi-Axis CNC Machining Equipment

Multi-axis CNC machining equipment (e.g., 4-axis or 5-axis) is pivotal for complex surface machining, widely used in automotive manufacturing CNC machines, aerospace precision machining, and rail transit part machining equipment.

2.1 Efficiency of Multi-Axis Linkage

- Three-Axis Limitations: Movement restricted to X, Y, Z axes, suitable for simple geometries but requiring multiple setups for complex surfaces.

- Four-Axis Machines: Add a rotational axis, reducing clamping needs partially.

- Five-Axis CNC Machining Centers: Enable simultaneous multi-axis movement, allowing flexible tool motion along surface contours, completing multi-face machining in a single setup, boosting efficiency by over 30%—ideal for new energy vehicle part machining.

2.2 Critical Hardware Features

- High-Rigidity Spindle: Withstands complex cutting forces, minimizing vibration for precision.

- Precision Servo System: Achieves micrometer-level motion control, meeting high-precision CNC equipment standards.

- Dynamic Error Compensation: Real-time deviation correction ensures consistent accuracy, widely used in 5G equipment manufacturing machines.

2.3 Tangible Benefits

In aerospace precision machining, 5-axis CNC equipment reduces machining time by 30%, delivers stable surface quality, and keeps clamping errors to the micrometer level, aligning with CNC machine manufacturers’ high standards.

3. CNC Programming and Software Optimization

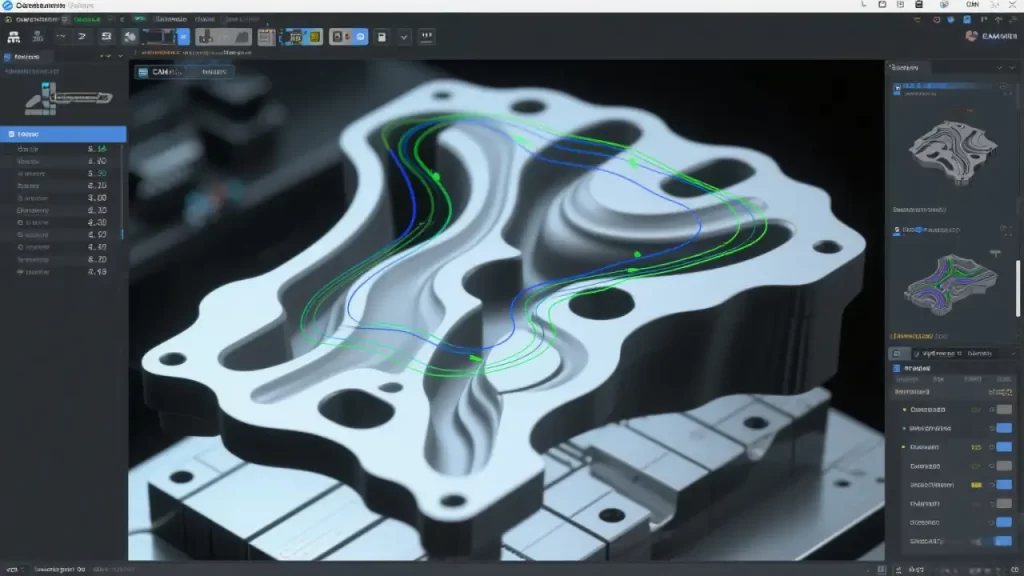

Effective CNC machining techniques and software optimization are critical for efficient and precise complex surface machining, directly impacting CNC machining center performance.

3.1 Role of CAM Software

- Core Functionality: Converts 3D models into tool paths, supporting multi-axis linkage.

- Popular Software: PowerMill and NX CAM excel at handling complex surfaces and optimizing cutting trajectories for precision machining equipment.

- Efficiency Gains: Automated path optimization reduces non-cutting time, ideal for automotive manufacturing CNC machines.

3.2 Tool Path Planning Strategies

- Contour Machining: Layered cutting suits gradual surfaces, offering high efficiency but potentially leaving slight steps.

- Streamline Machining: Tools follow surface flow, ideal for high-finish parts like aerospace precision machining blades.

- Region Segmentation: Divides surfaces into zones for optimized paths, minimizing tool interference, suitable for rail transit part machining equipment.

3.3 Simulation and Verification

- Purpose: Simulates tool motion to identify path errors or interference in advance.

- Benefits: Prevents workpiece or tool damage, reducing rework costs.

3.4 Programming Optimization Steps

- Import the 3D part model and analyze surface features.

- Select contour, streamline, or region segmentation strategies based on geometry.

- Set cutting speed and feed rate to balance efficiency and tool life.

- Run simulations to ensure interference-free paths, aligning with CNC machining automation standards.

4. Tool Selection and Cutting Parameter Optimization

Tool selection and parameter tuning are pivotal for CNC machining equipment efficiency, affecting machining quality and tool longevity.

4.1 Tool Selection

- Ball-End Mills: Ideal for smooth surfaces (e.g., new energy vehicle part machining), minimizing tool marks.

- Bull-Nose Mills: Suitable for roughing or semi-finishing flat-bottomed surfaces, balancing strength and precision.

- Geometry Considerations: Smaller-diameter tools suit fine machining but require lower speeds to prevent breakage.

4.2 Cutting Parameter Optimization

- Spindle Speed (RPM): 12,000–18,000 RPM for aluminum (common in 5G equipment manufacturing machines), 8,000–12,000 RPM for stainless steel.

- Feed Rate: 400–800 mm/min for stainless steel, higher for aluminum.

- Depth of Cut: 0.2–1.5 mm for complex surfaces to ensure precision and tool life.

4.3 Tool Path Strategies

- Zigzag Cutting: Layered machining for steep surfaces, potentially leaving minor ridges.

- Spiral Cutting: Continuous spiral paths enhance finish and efficiency, ideal for precision machining equipment.

4.4 Optimization Steps

- Select ball-end or bull-nose mills based on surface geometry.

- Start with conservative parameters, then adjust speed and feed rate.

- Choose zigzag or spiral paths to optimize surface quality.

5. Fixture and Workpiece Clamping Techniques

Stable clamping is foundational for CNC machining equipment efficiency and precision.

5.1 Fixture Design Principles

- Distributed Force: Prevents excessive clamping force from deforming workpieces, especially thin-walled parts.

- Surface Conformity: Fixture contact surfaces match workpiece shapes to reduce vibration.

- Quick Changeover: Supports diverse workpieces, enhancing CNC machining automation flexibility.

5.2 Fixture Types

- Rigid Fixtures: Ideal for simple shapes, offering high stability but limited flexibility.

- Flexible Fixtures: Adjustable clamping points or vacuum chucks adapt to complex surfaces, cutting setup time by 20%, suitable for rail transit part machining equipment.

- Zero-Point Clamping Systems: Enable rapid, precise setups with errors in the micrometer range.

5.3 Clamping Optimization Steps

- Analyze workpiece surface features to design optimal contact points.

- Prioritize flexible or vacuum fixtures for irregular shapes.

- Use zero-point systems to ensure repeatable clamping accuracy.

6. Quality Control During Machining

Real-time quality control ensures high-precision CNC equipment meets complex surface part requirements, encompassing in-process inspection and error compensation.

6.1 In-Process Inspection Technologies

- Laser Scanning: Captures surface geometry with micrometer accuracy, ideal for aerospace precision machining.

- Contact Probes: Measure critical features (e.g., mold holes), ensuring controlled dimensional deviations.

- Integrated Use: Real-time monitoring minimizes rework.

6.2 Error Compensation

- Functionality: CNC machining centers adjust tool paths in real time to correct for tool wear or workpiece deviations.

- Impact: Reduces machining errors from 0.05 mm to 0.01 mm.

- Key: Regular sensor calibration ensures data reliability.

6.3 Surface Finish Optimization

- Parameter Adjustment: Lower feed rates and higher spindle speeds reduce tool marks.

- Finishing Tools: Ball-end mills with small stepovers enhance smoothness.

- Streamline Paths: Minimize path transitions for better surface quality.

- Coolant Use: Lowers machining temperatures, improving finish.

7. Real-World Case Studies

7.1 Aerospace Turbine Blade (Titanium Alloy)

- Challenge: High hardness, complex geometry, surface finish of Ra 0.3 μm.

- Solution:

- 5-axis CNC machining center with streamline tool paths and ball-end mills.

- Feed rate of 300–600 mm/min, depth of cut 0.2–1.0 mm.

- Flexible fixtures with zero-point clamping, error <0.01 mm.

- Laser scanning for real-time inspection and error compensation.

- Outcome: 25% reduction in machining time, meeting aerospace precision machining standards.

7.2 Automotive Mold (Tool Steel)

- Challenge: Large volume, balancing efficiency with CNC machining center cost.

- Solution:

- 5-axis automotive manufacturing CNC machine with contour machining and bull-nose mills.

- Spindle speed of 8,000–12,000 RPM, feed rate of 800–1,200 mm/min.

- Modular fixtures, reducing setup time by 30%.

- In-process probe inspection, error <0.02 mm.

- Outcome: 20% shorter cycle time, 15% longer tool life.

7.3 Medical Implant (Stainless Steel)

- Challenge: High precision, surface finish of Ra 0.2 μm.

- Solution:

- 5-axis CNC equipment with spiral tool paths, ball-end mills, 0.1 mm stepover.

- Spindle speed of 10,000 RPM, depth of cut 0.3 mm.

- Vacuum fixtures to prevent thin-walled part deformation.

- Laser inspection and error compensation, deviation <0.005 mm.

- Outcome: Meets medical-grade precision, aligning with precision machining equipment standards.

8. Practical Tips for Boosting Efficiency

8.1 Process Optimization

- Parallel Machining: Multiple tools work on different areas simultaneously, reducing idle time.

- Minimized Non-Cutting Time: CAM software optimizes paths, cutting non-cutting time by 20%.

- Example: Automotive manufacturing CNC machines achieve 15% efficiency gains.

8.2 Equipment Maintenance

- Regular Calibration: Ensures multi-axis synchronization and positioning errors <0.01 mm.

- Lubrication and Cooling: Cleaning systems extends tool life by 30%.

- Benefits: 50% less downtime, mitigating CNC machining center cost impacts.

8.3 Operator Training

- CAM Software Proficiency: Mastering PowerMill saves 10% in path planning time.

- Machine Tuning: Quick adjustments to speed and feed rates suit new energy vehicle part machining.

- Troubleshooting: Identifying vibration or tool wear reduces scrap rates.

9. Conclusion

Efficient production of complex surface parts requires a holistic approach to optimizing CNC machining equipment, CNC machining techniques, and workflows:

- Multi-Axis CNC Equipment: Five-axis linkage reduces setups, boosting efficiency by 30%.

- CAM Programming: Streamline or segmented paths with simulation enhance precision and speed.

- Tools and Parameters: Ball-end mills with spiral paths balance efficiency and surface quality.

- Fixture Design: Flexible fixtures and zero-point systems ensure stability, supporting CNC machining automation.

- Quality Control: In-process inspection and error compensation keep errors below 0.01 mm.

- Efficiency Tips: Parallel machining, maintenance, and training cut cycles by 15–30%.

By leveraging optimized CNC machining solutions, CNC machining equipment delivers high-efficiency, high-precision production of complex surface parts, meeting the demands of aerospace precision machining, automotive manufacturing CNC machines, new energy vehicle part machining, rail transit part machining equipment, and 5G equipment manufacturing machines. Partnering with CNC machine manufacturer DELI and adopting CNC machining automation technologies significantly enhances production efficiency and industry competitiveness.