CNC Machining Center vs. CNC Milling Machine: Key Differences

In modern manufacturing, numerical control (NC) technology has revolutionized traditional machining processes. Among the core equipment in this transformation are CNC machining centers and CNC milling machines, both widely used across aerospace, automotive, medical device manufacturing, mold making, and precision component production.

While they may look similar at first glance, these two machine types differ fundamentally in design, automation level, processing capability, and ideal use cases. CNC machining centers, with their high degree of automation and multi-functional integration, have become the workhorses of mid-to-high-end production. Meanwhile, CNC milling machines remain popular for prototyping and small-batch jobs thanks to their flexibility and simplicity.

Despite their shared foundation in CNC-controlled milling, confusing the two can lead to poor equipment selection, inefficient capacity planning, or suboptimal return on investment—especially for newcomers or even seasoned professionals.

1. Core Definitions

1.1 What Is a CNC Milling Machine?

A CNC milling machine is a computer-controlled machine that uses a rotating cutting tool to remove material from a workpiece, shaping it into a desired geometry. The CNC system precisely guides the tool’s path along predefined axes—typically X, Y, and Z—to create complex profiles, slots, holes, and surfaces.

Most standard CNC mills operate on 3 axes, though some advanced models add a 4th axis (rotary A-axis) or even 5-axis capability. However, even in these cases, the machine usually requires manual intervention for tasks like tool changes, fixture adjustments, or repositioning the part. This limits throughput and repeatability in high-volume scenarios.

Per ISO 841, the standard coordinate system defines the Z-axis as aligned with the spindle, X as horizontal, and Y as perpendicular to the X-Z plane—ensuring consistency in programming and operation across machines.

1.2 What Is a CNC Machining Center?

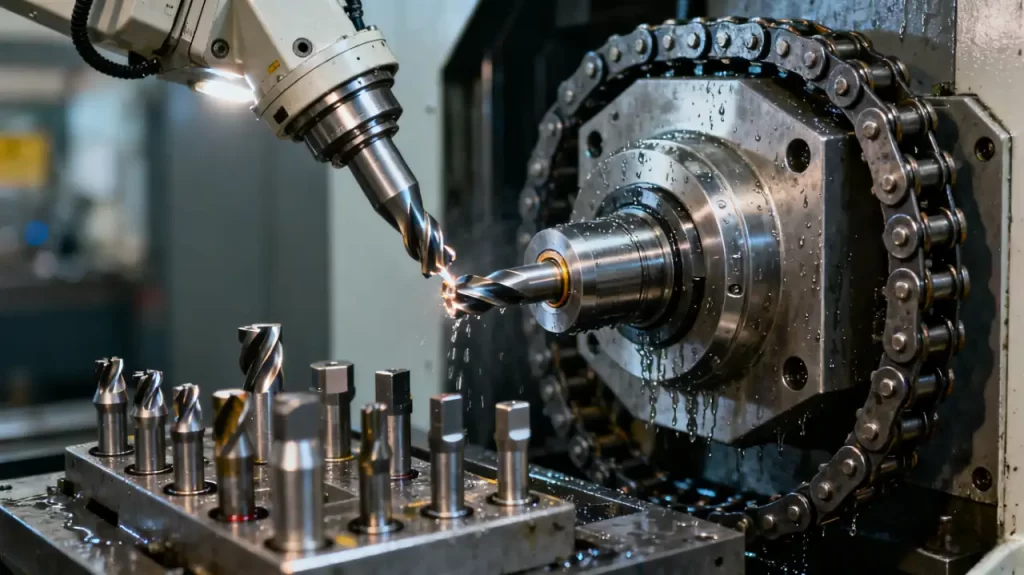

A CNC machining center is essentially a highly automated evolution of the CNC mill, distinguished primarily by its automatic tool changer (ATC) and integrated tool magazine. This allows it to perform multiple operations—milling, drilling, boring, tapping, countersinking, and more—in a single setup, without operator involvement.

Machining centers come in several configurations:

- Vertical Machining Centers (VMCs): Spindle oriented vertically; ideal for flat or disc-shaped parts like plates, flanges, and molds.

- Horizontal Machining Centers (HMCs): Spindle horizontal; excellent for box-type components requiring multi-sided machining and superior chip evacuation.

- Gantry or Bridge-Type Machining Centers: Built for large structural parts, such as those in aerospace or energy sectors.

These machines feature rigid cast-iron or polymer-concrete frames, precision-ground guideways, and advanced thermal compensation systems. As a result, modern machining centers routinely achieve repeatability within ±0.003 mm, far surpassing the typical ±0.01 mm of standard CNC mills—making CNC machining center accuracy a critical benchmark in high-precision manufacturing.

2. Key Differences at a Glance

| FEATURE | CNC MILLING MACHINE | CNC MACHINING CENTER |

|---|---|---|

| Automatic Tool Changer (ATC) | Usually absent; manual tool changes required | Standard feature with tool magazine (disc, chain, or matrix type) |

| Axis Configuration | Typically 3-axis; some 4-axis models | Commonly 3-, 4-, or full5-axis CNC machining center |

| Part Complexity | Best for flat surfaces & simple contours | Handles complex 3D geometries, freeform surfaces, and multi-sided parts in one setup |

| Production Efficiency | Suited for prototypes or low-volume runs; frequent downtime for tool changes | High-efficiency, continuous production; ideal for medium to high volumes |

| Rigidity & Precision | Moderate rigidity; adequate for general-purpose work | High rigidity, thermal stability, andprecision CNC machining center-grade performance |

| Typical Applications | Mold repair, R&D, education, jigs & fixtures | Aerospace components, engine blocks, surgical implants, precision gear housings |

2.1 The Automatic Tool Changer (ATC): The Defining Feature

The presence of an automatic tool changer is the single most reliable way to distinguish a machining center from a standard mill. Per ISO 230-2, a true machining center must be able to swap tools under program control, typically in 3–10 seconds.

Tool magazines vary by capacity and design:

- Disc (or “umbrella”) type: Compact and cost-effective; holds 16–24 tools; common in entry-level VMCs.

- Chain-type: Scalable and robust; supports 60+ tools; standard in industrial HMCs and high-throughput VMCs.

- Matrix-style: Found in high-end 5-axis systems; enables ultra-fast tool selection and parallel operations.

In contrast, changing tools on a CNC mill involves stopping the program, manually removing the old tool, installing a new one, and re-zeroing—taking 5–15 minutes per change and introducing human error risk. In one real-world case, a part requiring 8 operations took 45% non-cutting time on a mill, versus under 12% on a machining center.

2.2 Multi-Axis Capability: Positioning vs. Simultaneous Interpolation

While some CNC mills offer a 4th or 5th axis, these are often used for positional indexing—rotating the part to a fixed angle before locking it in place for 3-axis milling. True simultaneous 5-axis machining, however, requires all axes to move in coordinated, real-time interpolation.

This capability—standard in 5-axis CNC machining centers—allows the tool to maintain optimal contact with complex surfaces (e.g., turbine blades, orthopedic implants), reducing tool wear, improving surface finish, and eliminating the need for multiple setups.

According to ASME studies, multi-axis CNC machining can reduce total operations by over 60% and improve surface roughness (Ra) by 30–50%. For example, an aerospace turbine blade that would require 5 setups and 8 operations on a 3-axis mill can be completed in a single setup on a 5-axis machining center.

2.3 Rigidity, Precision, and Thermal Stability

Machining centers are engineered for high rigidity and thermal consistency. Their frames often use finite element analysis (FEA)-optimized ribbing, high-density cast iron, or vibration-damping polymer concrete. Spindles run on precision angular-contact or hydrostatic bearings, with speeds ranging from 3,000 to 24,000 RPM, and include active cooling to minimize thermal drift.

In contrast, standard CNC mills prioritize cost and versatility over extreme rigidity. Under sustained load, thermal expansion can cause drift of 0.02–0.05 mm, whereas high-end machining centers—using symmetrical thermal designs and real-time compensation—keep drift below ±0.005 mm.

Per the German VDI/DGQ 3441 standard:

- Machining centers: Positioning accuracy ≤ 0.010 mm/300 mm, repeatability ≤ 0.005 mm

- Standard CNC mills: Typically ≤ 0.020 mm and ≤ 0.010 mm, respectively

This gap explains why high-precision machining centers dominate in industries where microns matter.

2.4 Productivity and Automation Integration

One of the biggest advantages of a CNC machining center is its readiness for factory automation. It can be seamlessly integrated with:

- Pallet changers (for unattended operation)

- Robotic loading/unloading

- In-process probing (e.g., Renishaw systems for on-machine measurement)

- MES and Industry 4.0 platforms

For instance, in automotive engine block production, a horizontal machining center with a dual-pallet system can machine one part while another is being loaded—boosting Overall Equipment Effectiveness (OEE) to 85%+. Standard mills, lacking standardized automation interfaces, rarely fit into such flexible manufacturing systems (FMS).

3. Blurring Lines: Modern Trends

While the distinction remains clear in principle, technological advances are narrowing the gap.

3.1 “ATC-Equipped” Mills: A Gray Area

Some manufacturers now offer CNC mills with small automatic tool changers (8–12 tools), essentially creating budget-friendly, compact machining centers. These suit small shops or educational labs but lack the rigidity, speed, and software sophistication of true industrial machining centers.

33.2 Specialization Within Machining Centers

The category itself is diversifying:

- High-Speed Machining (HSM) Centers: ≥20,000 RPM spindles for aluminum and composites.

- Ultra-Precision Centers: Accuracy ≤0.003 mm for optics or semiconductor tooling.

- Mill-Turn Centers: Combine turning and milling in one machine for complete part processing.

3.3 Software and Intelligence Convergence

Modern CNC controls now support adaptive machining, digital twins, and remote diagnostics. Understanding how a machining center works today means recognizing it as a smart, closed-loop system—not just a mechanical tool. While even basic mills can adopt some smart features, the absence of ATC and structural limitations still prevent them from replacing true machining centers in complex production.

4. How to Choose? A Practical Decision Guide

Selecting the right machine depends on part complexity, batch size, precision needs, budget, and long-term automation goals.

4.1 When to Choose a CNC Milling Machine

- Prototyping & R&D: Frequent design changes; low repeatability needs.

- Low-volume, high-mix production: Custom fixtures, mold repairs, one-off parts.

- Education & training: Focus on G-code programming and basic operation.

- Tight budgets: Entry-level mills cost ⅓ to ½ of a comparable machining center.

Example: A mold shop repairing 20–30 injection molds per month—each needing minor milling or drilling—can operate efficiently with a CNC mill, avoiding unnecessary capital expense.

4.2 When to Choose a CNC Machining Center

- Medium to high-volume production: Where setup and changeover time dominate costs.

- Complex, high-precision parts: Aerospace brackets, medical implants, transmission housings.

- Multi-operation parts: Require milling, drilling, tapping—all in one clamping.

- Smart factory roadmap: Planning for lights-out production or MES integration.

Example: A medical device maker producing titanium hip stems reduced cycle time from 45 minutes to 18 minutes by switching from a 4-setup mill process to a 5-axis machining center. Scrap rates dropped from 3.2% to 0.5%, showcasing the real-world ROI of automation.

5. Common Misconceptions

Myth 1: “All CNC mills are machining centers.”

Reality: Only machines with an automatic tool changer qualify as machining centers. Many 3-axis CNC mills lack this feature entirely.

Myth 2: “Machining centers are always more accurate.”

Reality: Precision depends on build quality, maintenance, and environment. A well-maintained high-end mill (e.g., for optical surfaces) can outperform a low-end machining center. But at comparable price points, machining centers generally offer superior overall performance.

Myth 3: “5-axis = machining center.”

Reality: 5-axis refers to motion capability; machining center refers to automation and integration. You can have a 5-axis mill without ATC (used in art or research), and a 3-axis machining center with ATC (common in job shops). The two concepts are orthogonal.

6. Conclusion

While both CNC milling machines and CNC machining centers perform computer-controlled milling, they serve distinct roles in the manufacturing ecosystem.

- The CNC mill excels in flexibility, simplicity, and affordability—perfect for prototyping, education, and low-volume custom work.

- The CNC machining center dominates in automation, precision, and productivity—essential for complex, high-value, or high-volume production.

The presence of an automatic tool changer (ATC) remains the clearest differentiator. From there, differences in rigidity, multi-axis capability, thermal management, and integration potential define their respective strengths.

Choosing wisely isn’t about which machine is “better”—it’s about matching the tool to the task. In an era of lean manufacturing and digital transformation, understanding this distinction is key to optimizing both cost efficiency and competitive advantage.