CNC Machine Tools: Match Tool to Material, Not Machine

1. The Critical Role of CNC Machine Tools as System-Critical Components

In modern precision manufacturing, CNC machine tools are no longer viewed as mere platforms for material removal—they are the central execution nodes of the entire production system. While investment in high-accuracy five-axis machining centers has become commonplace, a significant proportion of facilities continue to experience elevated scrap rates, inconsistent surface finishes, and frequent tool failures—rooted not in machine capability, but in the misalignment between workpiece material properties and the selected CNC machine tools.

Industry data indicates that approximately 67% of premature CNC machine tools failures stem from inadequate consideration of material behavior during selection, rather than inherent tool defects. This underscores a fundamental truth: the performance of a manufacturing operation is determined not by the speed of the machine, but by the suitability of the CNC machine tools employed.

2. Fundamental Material Properties Governing CNC Machine Tool Performance

The durability and efficiency of CNC machine tools are governed by five intrinsic characteristics of the workpiece material, which collectively define the thermal, mechanical, and chemical loads imposed on the cutting edge.

| Material Property | Influence on CNC Machine Tools | Practical Example |

|---|---|---|

| Thermal Conductivity | Determines heat dissipation; low values cause excessive tip temperature rise | Titanium alloys (6.7 W/m·K) retain >80% of cutting heat in the tool |

| Elastic Modulus | Affects system stiffness; low values promote chatter instability | Aluminum alloys (~70 GPa) induce vibration in thin-walled components |

| Hardness | Directly accelerates abrasive wear mechanisms | HRC >55 hardened steels increase WC carbide wear rate by 3× |

| Work Hardening Tendency | Surface layer hardens during cutting, increasing cutting resistance | 304 stainless steel increases from HRC 20 to HRC 45+ post-cut |

| Chemical Reactivity | Promotes adhesion and diffusion wear at elevated temperatures | Titanium diffuses into WC substrates above 700°C, forming brittle intermetallics |

Additionally, materials with high elongation at break (e.g., aluminum >10%) generate long, continuous chips prone to entanglement. Highly reactive nickel-based superalloys undergo solid-state diffusion with tool substrates, leading to microstructural degradation and catastrophic failure.

3. Classification of Materials by Machinability: The Cutting Difficulty Index (CDI)

The industry-standard Cutting Difficulty Index (CDI) provides a quantitative framework for evaluating the demands placed on CNC machine tools across material classes:

| Difficulty Level | Material Examples | CDI Score | Required CNC Machine Tool Characteristics |

|---|---|---|---|

| I (Easy) | Free-machining steels | 2–3 | High edge sharpness, chip control, cost efficiency |

| II (Moderate) | Structural steels, 304/316 SS | 4–5 | Anti-adhesion, moderate wear resistance, toughness |

| III (Difficult) | Ti-6Al-4V, H13 tool steel | 6–7.5 | Thermal stability, diffusion resistance, damping |

| IV (Extreme) | Inconel 718, D2 (HRC ≥60) | 8–10 | CBN/PCD substrates, nano-coatings, high-pressure coolant support |

This classification is adopted as the foundational criterion for tool procurement and process standardization in aerospace, medical implant, and energy sectors.

4. CNC Machine Tool Substrates and Coatings: Material Architecture for Performance

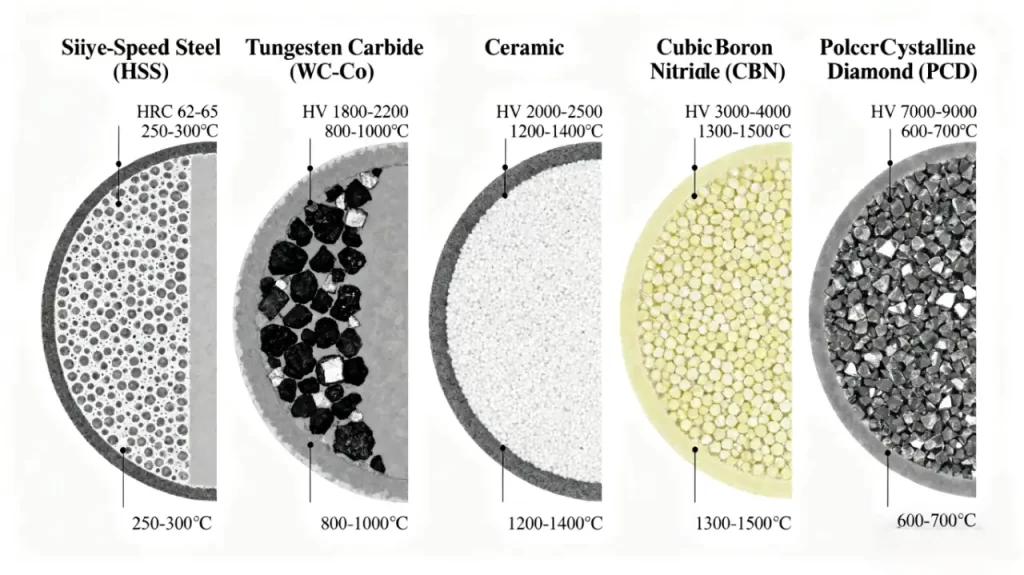

4.1 Substrate Materials for CNC Machine Tools

The substrate forms the structural backbone of CNC machine tools and determines baseline toughness, hardness, and thermal resilience.

| Substrate Type | Key Properties | Primary Applications | Compatible Materials |

|---|---|---|---|

| High-Speed Steel (HSS) | High fracture toughness (KIc ≈ 30 MPa·m1/2), impact resistant | Small-diameter drills, form tools | Free-machining steels, brass |

| Tungsten Carbide (WC-Co) | Hardness: 90–93 HRA; thermal stability up to 1000°C | >90% of general milling and turning tools | Steels, stainless steels, titanium |

| Ceramics | Thermal stability >1200°C; brittle | Dry machining of cast iron, interrupted cuts | Hardened steels, gray iron |

| Cubic Boron Nitride (CBN) | Second only to diamond in hardness; inert toward ferrous metals | Finishing of hardened tool steels | D2, H13 (HRC ≥55) |

| Polycrystalline Diamond (PCD) | Exceptional wear resistance; incompatible with ferrous alloys | Ultra-high-speed aluminum machining | 7075-T6, A356 |

Experimental results demonstrate that CNC machine tools fabricated from fine-grain tungsten carbide (0.3 μm grain size) exhibit a 58% increase in service life when machining Ti-6Al-4V compared to coarse-grain variants (1.2 μm). However, this improvement is accompanied by a 32% increase in chipping incidence—confirming that substrate microstructure must be matched to material-specific loading conditions.

4.2 Coating Technologies for Enhanced CNC Machine Tool Performance

Coatings significantly extend tool life and improve process stability by modifying surface friction, oxidation resistance, and chemical inertness.

| Coating Type | Coefficient of Friction | Max Operating Temperature | Optimal Application Context |

|---|---|---|---|

| TiN | 0.65 | 600°C | Low-carbon steels, brass |

| TiCN | 0.55 | 750°C | Stainless steels — superior anti-adhesion |

| TiAlN | 0.50 | 800°C | Mild steels, hardened tool steels |

| AlCrN | 0.48 | 900°C | Nickel superalloys, extreme thermal environments |

| DLC (Diamond-Like Carbon) | 0.20 | 400°C | Aluminum mirror finishing applications |

Laboratory testing under Inconel 718 machining conditions reveals that CNC machine tools coated with AlCrN exhibit 43% shallower crater wear than those with TiAlN coatings, with no evidence of Ni-W diffusion interaction—a critical advantage in high-temperature alloy processing.

4.3 Geometric Design Parameters of CNC Machine Tools

The geometry of CNC machine tools constitutes the interface through which the tool interacts with the workpiece. Optimization requires alignment with material behavior.

| Parameter | Design Principle | Material-Specific Recommendations |

|---|---|---|

| Rake Angle | Positive angles reduce cutting force; negative angles enhance edge strength | Aluminum: +20°; hardened steel: 0° to –5° |

| Clearance Angle | Larger angles minimize flank friction on sticky materials | Titanium: 14°; D2 steel: 8° |

| Lead Angle | Controls radial force and heat distribution | Deep cavity milling: 90°; contour profiling: 45° |

| Cutting Edge Angle | Manages chip direction and flow | Aluminum: +8°; interrupted cuts: –8° |

| Chipbreaker Geometry | Critical for chip segmentation and evacuation | Titanium: deep groove with negative rake profile |

A case study involving 7075-T6 aluminum machining demonstrates that reducing the lead angle from 90° to 45° decreased radial force fluctuation by 63% and reduced surface roughness (Ra) from 1.6 μm to 0.4 μm—highlighting the direct correlation between geometry and outcome.

5. Material-to-CNC Machine Tool Matching: Application-Specific Guidelines

5.1 Aluminum Alloys (7075-T6): Mitigating Adhesion and Chatter

- Challenges: High ductility → built-up edge; low thermal conductivity → localized heating; low modulus → system instability

- Recommended CNC Machine Tools: Polycrystalline diamond (PCD) inserts

- Coating: DLC or uncoated

- Geometry: +20° rake, 14° clearance, 45° lead, +8° cutting edge angle

- Cooling: Minimum Quantity Lubrication (MQL) with compressed air assist

- Outcome: Tool life exceeds 2,100 parts; Ra ≤ 0.35 μm; no secondary polishing required

Conclusion: For aluminum, surface smoothness of the CNC machine tools is more critical than edge sharpness. PCD’s inherent crystalline flatness suppresses adhesive phenomena.

5.2 Stainless Steels (304/316): Countering Work Hardening and Adhesion

- Challenges: Severe work hardening; low thermal conductivity; high chemical affinity for tool substrates

- Recommended CNC Machine Tools: Fine-grain WC-Co with TiCN coating

- Geometry: +8° rake, 12° clearance, 60° lead

- Cooling: High-pressure internal cooling (≥70 bar)

- Outcome: Tool life extended threefold; scrap rate reduced by 65%

Industry Insight: The challenge with stainless steel is not whether it can be cut—but whether the CNC machine tools can sustain consistent performance over extended cycles.

5.3 Titanium Alloys (Ti-6Al-4V): Managing Heat Accumulation and Diffusion

- Challenges: Extremely low thermal conductivity; strong chemical reactivity; susceptibility to chatter

- Recommended CNC Machine Tools: Ultra-fine grain WC-Co with AlCrN coating

- Geometry: +5° rake, 14° clearance, 90° lead, +6° cutting edge angle

- Cooling: Ultra-high-pressure internal coolant (120 bar) with emulsion

- Outcome: Tool life increased from 28 to 47 minutes; breakage rate reduced by 85%

Critical Note: Use of conventional TiAlN-coated CNC machine tools results in rapid crater wear within 30 minutes—demonstrating the necessity of material-specific tool design.

5.4 Nickel-Based Superalloys (Inconel 718): Withstanding Extreme Thermal Loads

- Challenges: Retains >800 MPa strength at 700°C; intense work hardening; rapid diffusion wear

- Recommended CNC Machine Tools: High-cobalt WC-Co with TiAlN/nano-multilayer hybrid coating

- Geometry: +3° rake, 13° clearance, 45° lead

- Cooling: Chilled coolant (5–10°C) combined with high-pressure internal delivery

- Outcome: Single-tool life reaches 42 minutes; productivity improved by 31%

Technical Advancement: Only AlCrN and multilayer TiAlN coatings effectively inhibit Ni-W interdiffusion, preserving substrate integrity under extreme conditions.

5.5 Hardened Tool Steels (H13 / D2, HRC 55–62): Enabling Milling as an EDM Alternative

- Challenges: Extreme hardness; micro-crack sensitivity; thermal fatigue risk

- Recommended CNC Machine Tools: Cubic boron nitride (CBN) inserts

- Geometry: 0° rake, 10° clearance, 60° lead, optimized chipbreaker profile

- Cooling: Dry machining or MQL

- Outcome: Machining time reduced from 6.5 hours to 1.8 hours; surface finish Ra = 0.2 μm; yield rate 99.2%

Strategic Impact: The adoption of CBN CNC machine tools has fundamentally altered moldmaking workflows—enabling “milling instead of EDM” as a repeatable industrial standard.

5.6 Brass (CuZn37): Controlling Chip Formation and Surface Integrity

- Challenges: High ductility → long, tangled chips; prone to tearing and surface irregularities

- Recommended CNC Machine Tools: High-cobalt WC-Co with TiN coating

- Geometry: +15° rake, 10° clearance, 90° lead

- Cooling: MQL

- Outcome: First-pass yield improved to 98.5%; no post-machining finishing required

Empirical Rule: Increased rake angle directly correlates with improved surface finish in brass—demonstrating geometric synergy with material plasticity.

5.7 Tin Bronze: Preventing Low-Melting-Point Alloy Welding

- Challenges: Melting point ~950°C; tin forms eutectics with tool substrates at elevated temperatures

- Recommended CNC Machine Tools: Fine-grain WC-Co with TiAlN coating

- Geometry: +12° rake, 12° clearance, 75° lead

- Cooling: Micro-lubrication with high-pressure air blast

- Outcome: Complete elimination of tool-tip welding; tool life extended to 210 parts

Key Consideration: Despite their relatively low hardness, copper-based alloys demand exceptional chemical compatibility in CNC machine tools—a single mismatched coating can result in batch rejection.

6. Implementation Framework for CNC Machine Tool Management

6.1 Establishment of a Material–CNC Machine Tool–Parameter Database

Organizations should implement a structured digital repository with the following fields:

| FIELD | EXAMPLE VALUE |

|---|---|

| Workpiece Material | Ti-6Al-4V |

| CNC Machine Tool Substrate | Fine-grain WC-Co |

| Coating | AlCrN |

| Rake Angle | +5° |

| Clearance Angle | 14° |

| Lead Angle | 90° |

| Cutting Edge Angle | +6° |

| Cooling Method | High-pressure internal |

| Tool Life | 47 min |

| Failure Mode | Crater wear |

Integration with CNC control systems enables real-time data capture, facilitating closed-loop optimization from trial runs to standardized procedures.

6.2 Standard Operating Procedure for CNC Machine Tool Selection

Decision Protocol:

- Identify workpiece material → Determine CDI rating → Define difficulty level

- Select appropriate substrate → Match coating technology → Specify geometric parameters

- Define cooling strategy → Execute first-article test → Document results in database

Mandatory Verification Checklist:

- Thin-wall component? → Use 45° lead angle to limit radial forces

- Presence of hard inclusions? → Require PCD or CBN substrates

- Mirror-surface requirement? → Employ nano-coatings and high spindle speeds

- Interrupted cutting cycle? → Utilize negative rake angles and high-toughness substrates

6.3 CNC Machine Tool Handling and Edge Conditioning Protocols

- Calibrate all CNC machine tools using a precision tool setter; length tolerance ≤ ±0.005 mm

- Apply controlled edge honing to WC-Co tools: Rz = 0.05–0.15 μm improves lifespan by 20–40%

- Prohibited practices: Sandpaper polishing, alcohol drying, humid storage

6.4 Economic Evaluation Model for CNC Machine Tools

Total Cost per Part = (Tool Cost ÷ Tool Life) + (Downtime Cost)

| Option | Tool Cost | Tool Life | Cost per Part | Downtime Cost | Total Cost |

|---|---|---|---|---|---|

| A | $35 | 35 pcs | $1.00 | $480 | $481 |

| B | $85 | 140 pcs | $0.61 | $120 | $120.61 |

Strategic Conclusion: Premium CNC machine tools typically achieve payback within 15 days. Their value lies not in initial cost, but in sustained output quality and operational reliability.

7. Conclusion: CNC Machine Tools as the Foundational Intelligence Layer

While automation and machine intelligence receive considerable attention in Industry 4.0 discourse, the most consequential variable in achieving consistent, high-yield production remains the CNC machine tool.

The distinction between leading manufacturers and lagging competitors is not defined by the number of machines installed, but by the depth of understanding applied to CNC machine tools selection, configuration, and lifecycle management.

From empirical tool replacement to data-driven prediction; from generic carbide inserts to material-optimized, coated, geometry-engineered solutions—the evolution of CNC machine tools reflects the maturation of manufacturing science itself.

When a technician can accurately specify: “This titanium component requires ultra-fine-grain WC-Co with AlCrN coating, 120-bar internal coolant, and a 90° lead angle,” they are no longer merely operating equipment. They are deploying engineered intelligence at the cutting interface.

The future of manufacturing does not belong to those with the largest fleet of machines. It belongs to those who master the science of CNC machine tools.