CNC Machine Tools

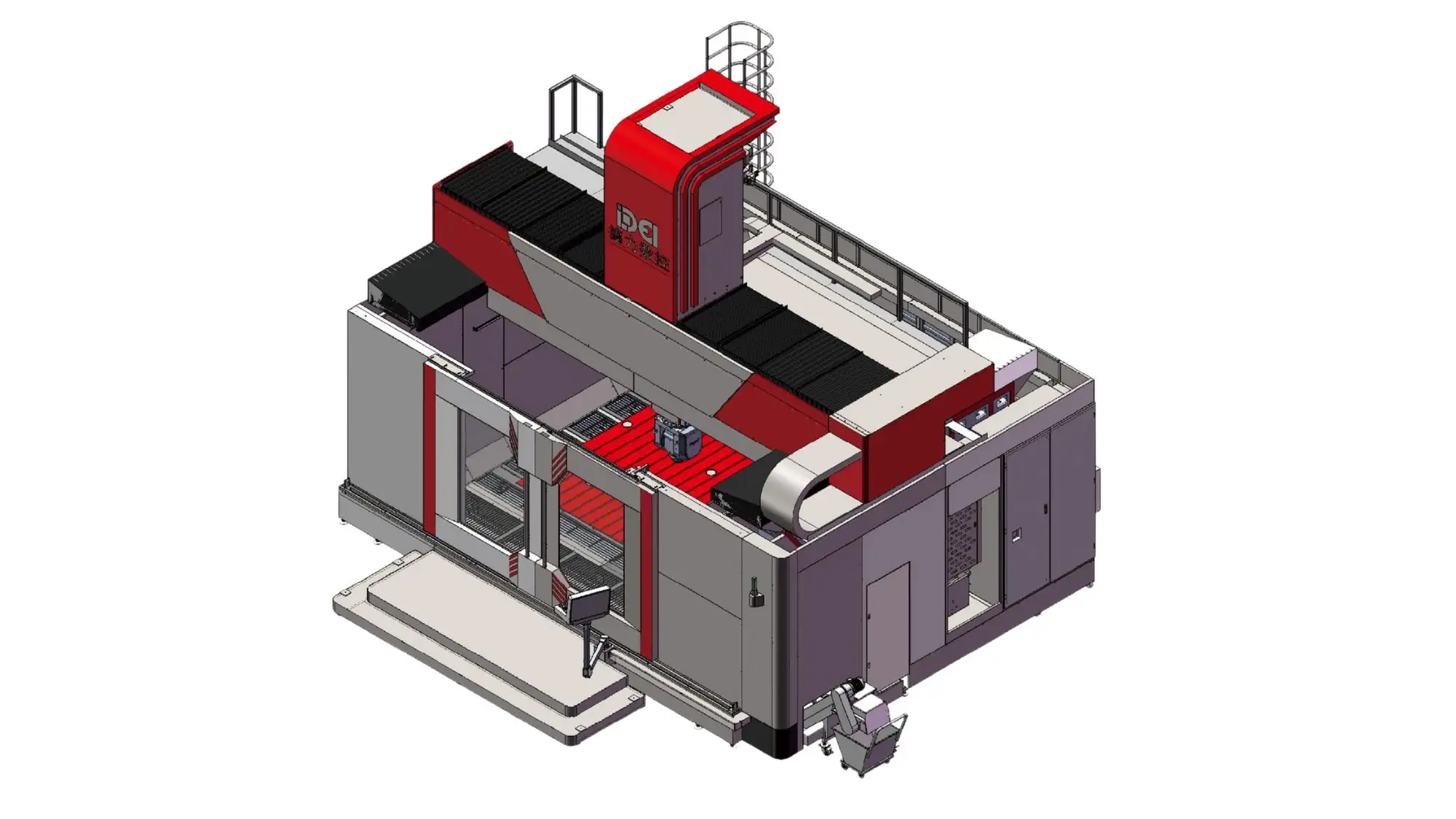

HK4025 Crane Type Five Axis Machining Center

The SCH series CNC vertical machining center is a high-rigidity CNC machine tool designed for heavy-duty cutting and high-efficiency processing. It is widely used in industries such as aerospace, automotive manufacturing, energy equipment, mold processing, and mechanical manufacturing. The series adopts a stable vertical structure, offering excellent cutting capability and stability, and can meet the processing needs of complex parts, including milling, drilling, tapping, and boring.

Hk3020 Bridge Type Five Axis Machining Center

The SCH series CNC vertical machining center is a high-rigidity CNC machine tool designed for heavy-duty cutting and high-efficiency processing. It is widely used in industries such as aerospace, automotive manufacturing, energy equipment, mold processing, and mechanical manufacturing. The series adopts a stable vertical structure, offering excellent cutting capability and stability, and can meet the processing needs of complex parts, including milling, drilling, tapping, and boring.

CNC Milling Machining Column SCH

The SCH series CNC vertical machining center is a high-rigidity CNC machine tool designed for heavy-duty cutting and high-efficiency processing. It is widely used in industries such as aerospace, automotive manufacturing, energy equipment, mold processing, and mechanical manufacturing. The series adopts a stable vertical structure, offering excellent cutting capability and stability, and can meet the processing needs of complex parts, including milling, drilling, tapping, and boring.

CNC Vertical Machining Center SCD

The CNC vertical machining center (SCD series) is a high-precision, high-rigidity CNC machine tool designed for heavy-duty cutting and efficient processing. It is widely used in aerospace, automobile manufacturing, energy equipment, mold processing and machinery manufacturing industries. This series adopts a stable vertical structure, has excellent cutting ability and stability, and can meet the processing needs of milling, drilling, tapping and boring of various complex parts.

CNC Milling Machining CNC Vertical Machinhing Center Double Column Machining Center SCA

The CNC vertical machining center (SCA series) is a high-precision, high-rigidity CNC machine tool designed for heavy-duty cutting and efficient processing. It is widely used in aerospace, automobile manufacturing, energy equipment, mold processing and machinery manufacturing industries. This series adopts a stable vertical structure, has excellent cutting ability and stability, and can meet the processing needs of milling, drilling, tapping and boring of various complex parts.

3 Axis CNC Gantry Machining Center MD

The MDF series five-axis CNC gantry machining center is a high-precision, high-rigidity CNC machine tool designed for complex surface processing and efficient production. It is widely used in high-end industries such as aerospace, automobile manufacturing, shipbuilding industry, energy equipment and mold manufacturing. The equipment adopts a gantry structure and combines five-axis linkage technology to achieve efficient multi-angle processing and meet the manufacturing needs of high-precision parts.

3 Axis CNC Gantry Machining Center HCK

CNC vertical machining center (HCK series) is a high-precision, high-efficiency CNC machine tool, widely used in machinery manufacturing, aerospace, automotive parts, electronics and mold processing industries. The equipment adopts a vertical structure with the spindle perpendicular to the worktable, suitable for milling, drilling, tapping and boring of complex parts.

CNC Vertical Machining Center HA

CNC vertical machining center (HA series) is a high-precision, high-efficiency CNC machine tool, widely used in machinery manufacturing, aerospace, automotive parts, electronics and mold processing industries. The equipment adopts a vertical structure with the spindle perpendicular to the worktable, suitable for milling, drilling, tapping and boring of complex parts.

CNC Vertical Machining Center HB4D

CNC vertical machining center (HB4D series) is a high-precision, high-efficiency CNC machine tool, widely used in machinery manufacturing, aerospace, automotive parts, electronics and mold processing industries. The equipment adopts a vertical structure with the spindle perpendicular to the worktable, suitable for milling, drilling, tapping and boring of complex parts.

CNC Vertical Machining Center HB

CNC vertical machining center (HB series) is a high-precision, high-efficiency CNC machine tool, widely used in machinery manufacturing, aerospace, automotive parts, electronics and mold processing industries. The equipment adopts a vertical structure with the spindle perpendicular to the worktable, suitable for milling, drilling, tapping and boring of complex parts.

CNC Vertical Machining Center MC

CNC vertical machining center (MC series) is a high-precision, high-efficiency CNC machine tool, widely used in machinery manufacturing, aerospace, automotive parts, electronics and mold processing industries. The equipment adopts a vertical structure with the spindle perpendicular to the worktable, suitable for milling, drilling, tapping and boring of complex parts.

Door and Winows CNC Fabrication Equipment SP

SP series curtain wall CNC processing equipment is a high-precision, high-efficiency CNC processing equipment designed for the aluminum alloy, steel structure and glass curtain wall manufacturing industries. This series of equipment integrates drilling, milling, tapping and cutting functions, and is widely used in building curtain walls, door and window manufacturing, photovoltaic brackets and metal component processing, etc., to meet the production needs of high-precision and high-quality curtain wall components in the modern construction industry.

Curtain Wall CNC Fabrication Equipment MF

MF series curtain wall CNC processing equipment is a high-precision, high-efficiency CNC processing equipment designed for the aluminum alloy, steel structure and glass curtain wall manufacturing industries. This series of equipment integrates drilling, milling, tapping and cutting functions, and is widely used in building curtain walls, door and window manufacturing, photovoltaic brackets and metal component processing, etc., to meet the production needs of high-precision and high-quality curtain wall components in the modern construction industry.

LP-F900 Large Seven-Axis Compound Angle Dual-Head Saw

The LP-F900 Large Seven-Axis Compound Angle Dual-Head Saw is designed for precise multi-angle cutting of industrial profiles and aluminum curtain wall materials. It offers adjustable angles for both the worktable (22.5°-140°) and saw blade (45°-90°), ensuring high accuracy and smooth operation. With a precision feeding system and robotic reducer, it guarantees reliable cutting performance and accurate length control.

LP-900A-650 Precision CNC Arbitrary Angle Double Head Saw

The LP-900A-650 is a precision CNC double head saw designed for cutting industrial and aluminum curtain wall profiles at multiple angles. Its swing arm structure allows simultaneous or individual cutting by both saw heads, boosting productivity. Equipped with imported servo motors and precision components, it ensures reliable performance and accuracy. The swing angles range from 22.5° to 135°, controlled by robot RV reducers. It also features an automatic chip removal system and aluminum chip collection bin for easy operation.

LP-900G Large CNC Arbitrary Angle Double Head Saw

The LP-900G is a large CNC double head saw designed for cutting large aluminum alloy profiles at any angle. Its dual saw blade system enables simultaneous operation, significantly improving work efficiency. The machine is equipped with an imported Italian direct-output motor, ensuring high performance. It utilizes linear guide rails for both cutting and drive mechanisms, powered by a servo motor for precision. The saw also features a protective cover, providing full safety for operators during use. This model is ideal for applications requiring high precision and large-scale cutting capabilities.

LP-900D-450 CNC Double Head Saw – Rotary Type

The LP-900D-450 CNC double head saw with a rotary type design is a high-precision cutting machine used primarily for cutting aluminum profiles in industries such as windows and doors, curtain walls, and industrial aluminum. It features a rotary swing structure that allows for multi-angle cutting, ensuring flexibility and efficiency in various applications. This machine is designed for precise, fast, and stable cutting, suitable for materials like aluminum in various industries, including automotive parts and construction.

LP-900B-550 CNC Double-Head Saw-Swing Out

This machine is designed for precision cutting of aluminum alloy and profiles at 45° and 90°. It features a specialized swing arm knife structure for smooth and accurate cutting surfaces. A manual roller support rack is included to prevent material sagging and slipping during operation. Additionally, the precision direct-connected sawing motor minimizes blade vibration, ensuring high-accuracy cutting performance.