CNC Machine Cost 2025: Key Cost Drivers Every Global Buyer Must Understand

Welcome to 2025 — where global manufacturing is being reshaped by smart factories, flexible production, green mandates, and supply chain resilience. These aren’t buzzwords anymore. They’re operational imperatives.

At the heart of it all? The CNC machine — the “mother of all machines.” Buying one today is no longer a simple equipment purchase. It’s a strategic investment that touches Total Cost of Ownership (TCO), production ramp-up speed, technology compatibility, and future scalability.

Yet, too many manufacturers still shop by price tag alone — fixated on the initial quote while ignoring the hidden costs that pile up over time: energy bills, maintenance headaches, unplanned downtime, integration bottlenecks, and upgrade dead ends.

According to the Association For Manufacturing Technology (AMT), the upfront purchase price accounts for only 40–50% of a machine’s 5-year TCO. The other 50–60%? That’s where profits quietly vanish — in operational inefficiencies.

Unplanned downtime. Energy-guzzling operation. Inefficient CNC machining. Poor compatibility with future upgrades. Ignore these, and your CNC Machine Cost will spiral out of control — long after the ink dries on the purchase order.

Core Component Selection — The Art of Balancing Performance and Price

CNC Control System: Not the Most Expensive — But the Most Appropriate

Think of the control system as your machine’s brain. Your choice here directly impacts stability, precision, and — crucially — your ability to upgrade down the road.

In 2025, the big names remain Siemens, FANUC, Mitsubishi, and Heidenhain — but open-platform solutions with global validation are gaining serious traction.

- Standard machining? Stick with a proven, mature control system + deep-process optimization packages (think mold surface compensation, high-speed corner smoothing). This combo covers 95%+ of applications — and delivers the best bang for your buck.

- High-end, complex work? For 5-axis machining, micron-level contouring, or high-speed sculpting, go for Siemens 840D or FANUC 31i/32i. But here’s the catch: Don’t pay for features you’ll never use. Multi-channel control, 3D simulation, or advanced CAM interfaces might sound impressive — but if your machine runs a single operation, you’re wasting 10–15% on software licenses you’ll barely touch.

- Critical tip: Open communication protocols (OPC UA, MTConnect, Umati) matter more than brand names. Closed systems force you to install gateways — or worse, swap controllers — when integrating with MES or digital twin platforms. That retrofit can cost you 8–12% of the original machine price. For shops chasing precision machining, protocol openness = future-proof automation.

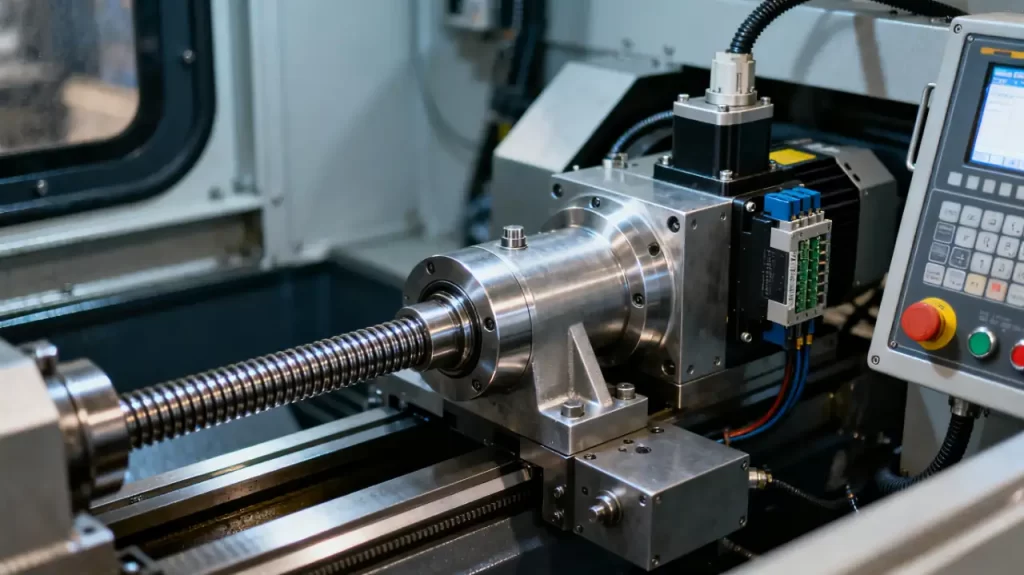

Servo & Transmission: Precision ≠ Over-Engineering. Match the Tech to the Task.

Servo drives and precision transmission components (ball screws, guides, bearings) dictate dynamic accuracy and long-term stability.

In 2025, with direct-drive tech, preload compensation, and thermal drift control becoming mainstream, the game has changed: it’s no longer “bigger specs = better.” It’s “right specs for the job.”

- Standard milling/turning? High-precision ball screws + pre-stretched assembly deliver ±3μm repeatability at a fraction of the cost. Pair them with efficient servo motors, and you’ve got the sweet spot for CNC lathes and CNC mills.

- High-speed, mirror-finish, micron-level work? Go direct-drive: linear motors + torque motors eliminate backlash and friction. Acceleration hits 2G+, surface finish Ra<0.2μm. But do the math: direct-drive adds 15–30% to your machine cost. Only worth it if you’re running >3,000 hours/year and your parts carry >30% added value.

- Material cost volatility? Rare-earth magnets make up 35–45% of servo motor cost — and prices swung ±25% in 2024. Partner with suppliers offering “price linkage agreements” to hedge against cost spikes. Industry data shows this can slash cost volatility from 0.9 to 0.6.

Machine Base: Rigidity, Thermal Stability, Lightweight — Pick Two (Wisely)

The base is your machine’s skeleton. Its design dictates vibration resistance, thermal behavior, and dynamic response.

In 2025, material and process innovations offer more options — but you must choose based on your workload and environment.

- Cast iron? Still the value king. High damping, low cost, proven reliability. Perfect for most metal-cutting jobs — expect <5μm precision drift over 5 years.

- Mineral casting (synthetic granite)? Thermal expansion is 1/10th of cast iron, damping 3x better. Ideal for ultra-precision mirror finishes or optical molds (precision machining territory). But it’s 30–50% pricier and fragile under heavy cuts — avoid for roughing.

- Welded steel + damping filler? Topology-optimized structure filled with polymer damping material strikes a balance between rigidity and weight. Great for large gantries — cuts delivery time by 40% and cost by 15%.

- Lightweight trap: Carbon fiber or honeycomb aluminum? Fine for moving parts (cross beams, saddles). But never sacrifice mass in the main base — it’ll amplify low-frequency vibrations and wreck surface quality.

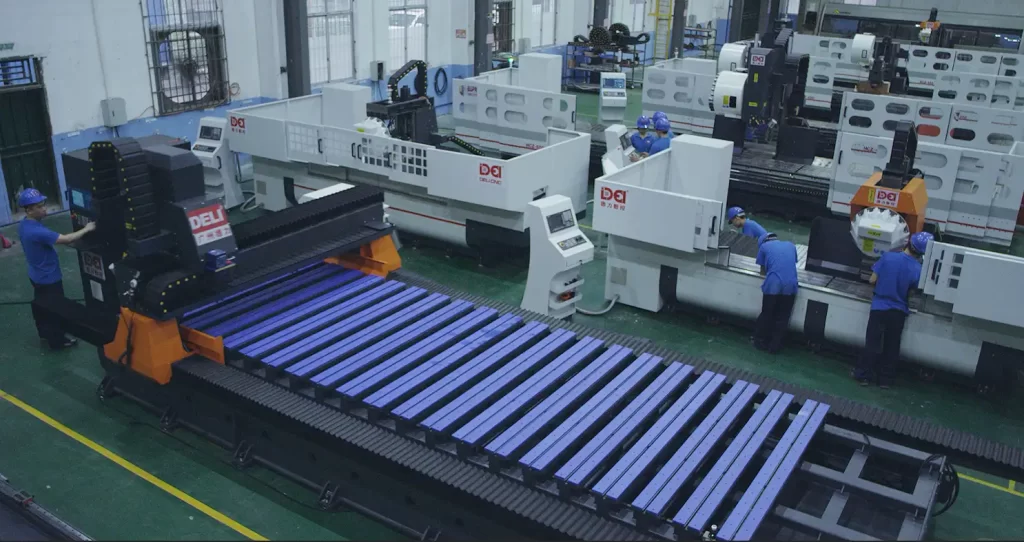

Smart Manufacturing Isn’t a Cost — It’s a Profit Multiplier

Virtual Commissioning & Digital Twin: Cut Delivery Time = Cut Capital Cost

Old-school machine delivery means weeks of on-site tweaking — 7 to 15 days of idle lines, wasted materials, and flying engineers.

In 2025, Model-Based Systems Engineering (MBSE) and digital twins are rewriting the rules.

- Ship with 90% of commissioning done virtually (PLC logic, motion paths, collision checks). Customers go live in 3 days. Real-world results: 30% fewer physical prototypes, 45% less scrap.

- Get a full digital twin (motion envelope, interface coordinates, energy curves) to simulate layout and cycle times in your MES/PLM before installation. One EV battery housing plant cut integration time by 22 days — saving over $120K in engineering costs.

Modular Architecture: Build a Machine That Grows With You

Modularity is your shield against uncertainty and tech obsolescence.

In 2025, top manufacturers offer standardized modules for spindles, tool changers, rotary tables, and control cabinets.

- Upgrade spindle speed later? (7,000 → 15,000 rpm?) Base models come pre-wired and pre-drilled. Upgrade cost? Just 30–40% of a new machine.

- Tool magazine expandable? Start with 24 tools, grow to 60, then 120 — scale with your order book, not your fears.

- Standardized modules slash spare part SKUs by 50%+ and cut repair time by 60%. One auto parts maker slashed MTTR from 8.5 to 3.2 hours.

Predictive Maintenance: Fix It Before It Breaks

Unplanned downtime is the silent profit killer.

McKinsey estimates $260,000/hour lost in high-end manufacturing.

In 2025, predictive maintenance (PdM) isn’t optional — it’s table stakes for controlling CNC machine maintenance cost.

- Tri-sensor suite (vibration + temp + current) + edge computing monitors spindle bearings, ball screws, and guideways. Flags issues 7–14 days early — 92% accuracy, <3% false alarms.

- Remote diagnostics with video + AR markup + data sharing solve 80% of issues remotely. One European mold shop saved 147 downtime hours — $120K direct, $300K in avoided order penalties.

- Optional “Health Report Subscription”: Monthly automated reports on component lifespan, maintenance tips, energy use. Turns guesswork into planning.

In an Age of Supply Chain Chaos, Pick Partners Who Deliver — and Control Costs

Multi-Source Strategy: No Single Point of Failure

Geopolitical risks and trade wars mean supply chain resilience is now a core procurement criterion.

Leading 2025 manufacturers operate “Asia + Europe + North America” triple-sourcing.

- Encoders (Heidenhain vs. Tamagawa vs. Renishaw), drives (Yaskawa vs. Delta vs. Beckhoff), bearings (NSK vs. Schaeffler vs. LYC) — all have backup suppliers. Switch within 72 hours if disaster strikes.

- Regional hubs (Germany, US, Singapore) + local service points = critical spares in 48 hours. One Southeast Asian plant avoided $70K in downtime during port chaos — thanks to local stock.

Tech Sovereignty: Avoid Getting “Regulation-Locked”

High-end 5-axis machines face export controls — stretching delivery to 9–12 months.

The 2025 solution? Homegrown CNC kernels + open software stacks.

- 100% in-house RTCP (Rotary Tool Center Point), 5-axis post-processors, G-code interpreters = no export license headaches. Delivery? Stable at 4–6 months.

- Software deployable on-premise — data never leaves your factory. Compliant with GDPR, ISO 27001. And avoid MATLAB/Simulink for embedded code — licensing risks lurk. G-code compatibility and openness are your best predictors of CNC machine tools future flexibility.

Green Compliance: Pay Now — or Pay More Later

EU CBAM carbon tariffs, US Clean Competition Act — the rules are murky, but the direction is clear: low-carbon manufacturing is mandatory.

Machine efficiency and recyclability will soon be gatekeepers.

- IE4/IE5 motors + variable-frequency hydraulics = standby power <1.5kW, 25–40% energy savings. One appliance maker saved $65K/year.

- Optional recycled cast iron (>85% recycled content) + full carbon footprint report (materials, manufacturing, transport, operation). Prepares you for audits. And yes — ISO 9001:2015 certification matters. It signals environmental compliance and quality control — directly impacting CNC machine with ISO 9001 cost.

When Labor Is Scarce and Expensive, Make Your Machine Work Harder — Not Your People

Human-Machine Interface: From Code to Click

Skilled machinists are in short supply.

In 2025, CNC interfaces are ditching G-code hell for intuitive, visual workflows.

- Drag-and-drop programming + 300+ built-in process templates (deep hole drilling, thread milling, surface finishing) = new hires productive in 3 days. Training costs drop 70%.

- Optional voice control (“Run Program A,” “Pause Feed,” “Call Tool 5”) reduces errors. AR glasses overlay torque specs and assembly guides — digitizing your master machinist’s brain.

Automation-Ready Design: Leave the Door Open for “Lights-Out” Factories

Your machine’s ability to plug into automation defines your next 3–5 years of scalability.

In 2025, the best machines ship “automation-ready.”

- Pre-wired for robots (Profinet/EtherCAT) + standardized mechanical interfaces (air, signals, locators) = 40–60% cheaper integration.

- Pre-integrated with KUKA, FANUC, ABB — turnkey “machine + robot + pallet system” packages. One medical device shop cut night-shift labor by 35%. For small shops hunting machine shop solutions, this slashes CNC machine for small shop cost dramatically.

Remote Support: Your Expert, On Demand — Not On a Plane

Traditional service = waiting days for a flying engineer.

In 2025, remote collaboration is standard.

- Scan a QR code → launch AR support. Engineers annotate your screen, share data, even control your HMI. Average response? Under 2 hours (vs. industry’s 24).

- Optional “VIP Support Plan”: Unlimited remote help + priority spares + quarterly health reports. Costs 3–5% of machine price/year — but slashes emergency failure losses by 80%+. Multilingual support (EN/ES/DE/FR/AR) for global ops.

TCO Deep Dive — Electricity, Tools, Downtime, Retros: Which One’s Eating Your Profits?

Energy Costs: High Power ≠ High Output. Efficiency Does.

CNC machines are energy hogs — and electricity’s share of TCO is climbing.

In 2025, efficiency is a competitive weapon.

- Spindle, hydraulics, coolant — the big three energy sinks. Choose variable-speed spindles, standby modes (<15% power when idle), smart cooling (temp-triggered) = 15–25% energy savings.

- Demand “real-world energy curves” — not theoretical specs. One shop optimized cutting parameters and cut per-part energy use by 18%. Accurate CNC machine hourly operating cost is your first step to true ROI.

Tooling & Consumables: Small Line Item, Big Leak

Tooling costs are often ignored — yet they eat up 15–25% of machining expenses.

In 2025, smart tool management is your secret weapon.

- Tool life prediction (based on cutting force, vibration, acoustic emission) extends tool life 10–20% — cuts per-part cost 5–15%.

- Smart tool scheduling reduces air time and tool-change delays — boosts productive machining time 8–12%. One connector maker saved $32K/month.

Downtime: The Cost You Never See — Until It’s Too Late

Unplanned downtime is the black hole of TCO.

Fraunhofer Institute estimates: Manufacturing loses 0.8–1.2% of machine value per hour of downtime.

- One spindle bearing failure = 12 hours down. Direct cost (overtime, lost output) + indirect (delayed orders, penalties) = 10–15% of machine value.

- A supplier with “self-diagnosis + rapid spare delivery” is worth more than a $10K discount. Predictive maintenance + regional spares = 70%+ less downtime loss.

Your 2025 CNC Buying Checklist — 7 Questions That Reveal the True Cost

Before signing anything, grill your supplier on these 7 points. They’re the key to unlocking real CNC Machine Cost visibility:

- Can I upgrade modules later? What mechanical, electrical, and software pathways are pre-built?

- Are open protocols (OPC UA/MTConnect) standard? What’s the projected cost to integrate with MES/CAD/CAM?

- Is predictive maintenance included? Which components are monitored (spindle, screw, guide, hydraulics)? Directly impacts CNC machine maintenance cost.

- Is remote + AR support standard? What’s your average response time and first-time fix rate (FTR)? Multilingual?

- Do you have multi-source backups for critical parts? Are common spares stocked in my region (NA/EU/SEA)?

- What’s the machine’s energy rating? Does it include standby modes and adaptive load control? Critical for CNC machine hourly operating cost.

- Can you provide a “5-year TCO template”? Including energy, maintenance, tools, and downtime? Essential for evaluating cost of CNC machine tools.

Final Thought: The Cheapest Machine Is Often the Most Expensive One You’ll Ever Buy

In 2025, smart manufacturers don’t buy machines — they invest in production ecosystems.

Look beyond the quote. Calculate the lifetime cost. Choose a partner — not just a product.

Because when you factor in energy, downtime, labor, upgrades, and compliance…

The real cost isn’t what you pay upfront. It’s what you pay over time.