Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

CNC Machining vs. Manual Machining: How to Choose?

BlogIn manufacturing, the choice of machining method is never trivial. Do you go with highly automated CNC machining, or rely on the seasoned hands of a skilled machinist using manual techniques? This decision doesn’t just affect part accuracy and consistency—it directly influences production efficiency, cost structure, and even your company’s competitive edge. This article breaks… Continue reading CNC Machining vs. Manual Machining: How to Choose?

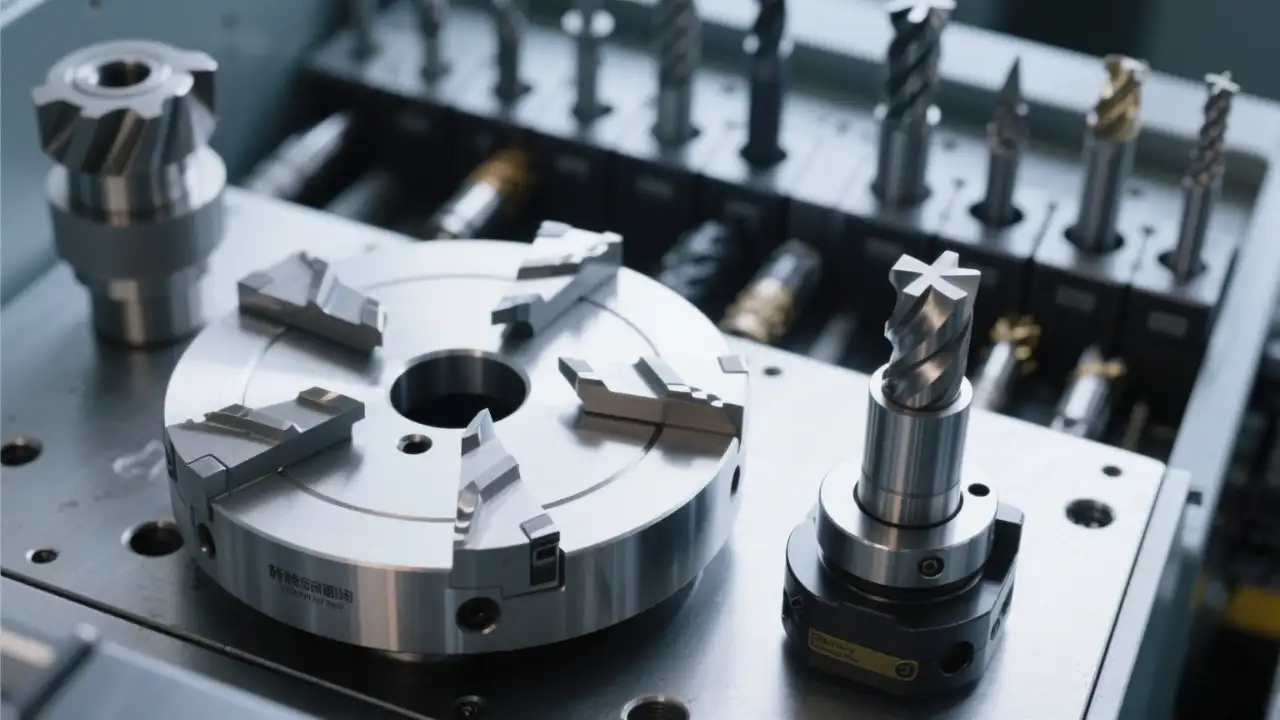

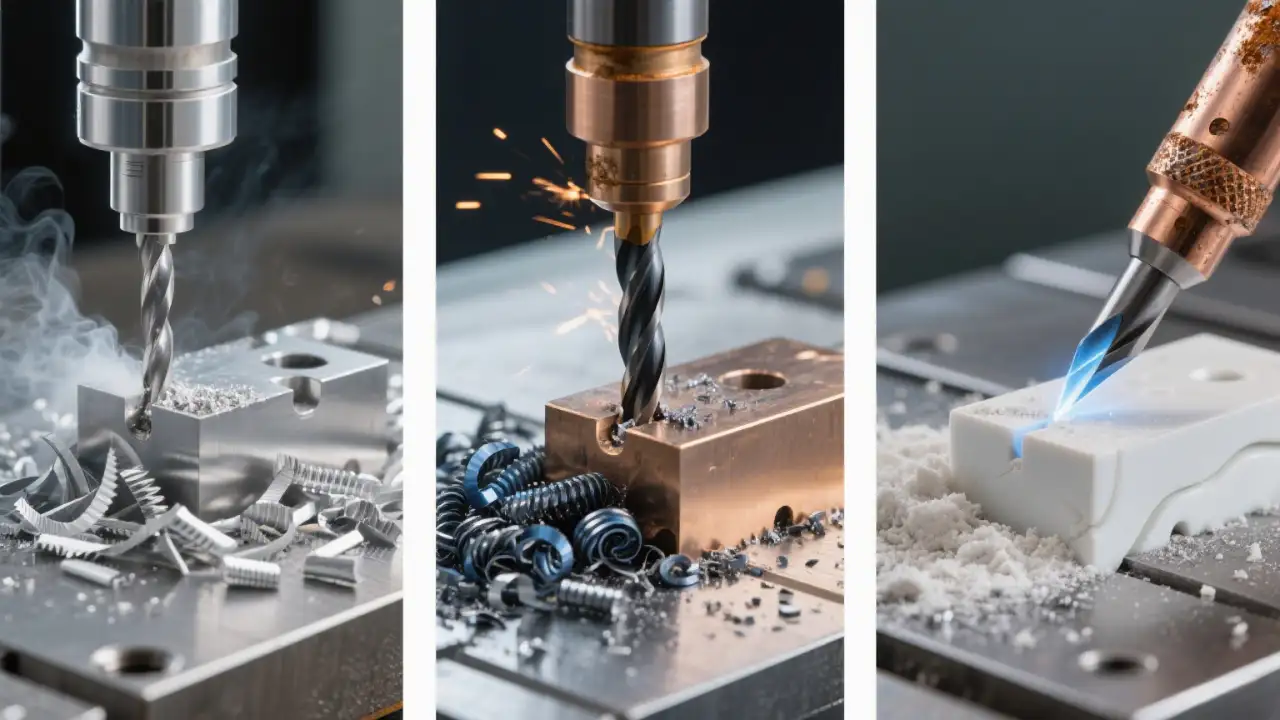

CNC machining tools: Types, Uses, Selection Tips

BlogIn modern precision manufacturing, CNC machining tools serve as the core execution units of cutting processes. Their performance and compatibility directly determine machining efficiency, surface quality, and process stability. As CNC machine tools evolve toward high speed, high precision, and multi-axis compound processing, the coordinated optimization of CNC cutting tools and tool grinders has become… Continue reading CNC machining tools: Types, Uses, Selection Tips

A Comprehensive Guide to CNC Machining Parameters

BlogIn modern CNC machining, selecting the right parameters is not just about speed or feed—it’s about understanding the underlying physics of cutting, material behavior, and system dynamics. From aerospace to medical devices, CNC machining drives precision manufacturing, and mastering its core parameters—cutting speed, spindle speed, feed rate, depth of cut, cooling, and toolpath—is essential for… Continue reading A Comprehensive Guide to CNC Machining Parameters