Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

The Ultimate Guide to Choosing the Best CNC Machining Centers in 2025

August 07, 20251. Why Choosing the Right CNC Machining Center Matters CNC machining centers (Computer Numerical Control equipment) are the backbone of modern manufacturing, powering industries like automotive, aerospace, renewable energy, rail transport, and 5G electronics with precision and efficiency. Picking the right machine isn’t just about buying equipment—it directly impacts productivity, cost management, and product quality.… Continue reading The Ultimate Guide to Choosing the Best CNC Machining Centers in 2025

10 Practical Tips to Improve CNC Machining Efficiency

August 06, 2025CNC machining powers modern manufacturing. Improving CNC machining efficiency slashes costs, speeds up delivery, and sharpens your competitive edge. This guide shares 10 practical tips, from refining tool paths to leveraging simulation software, to elevate your process. Start optimizing now! Tip 1: Boost CNC Machining Efficiency with Tool Path Optimization Advanced CAM software like Mastercam… Continue reading 10 Practical Tips to Improve CNC Machining Efficiency

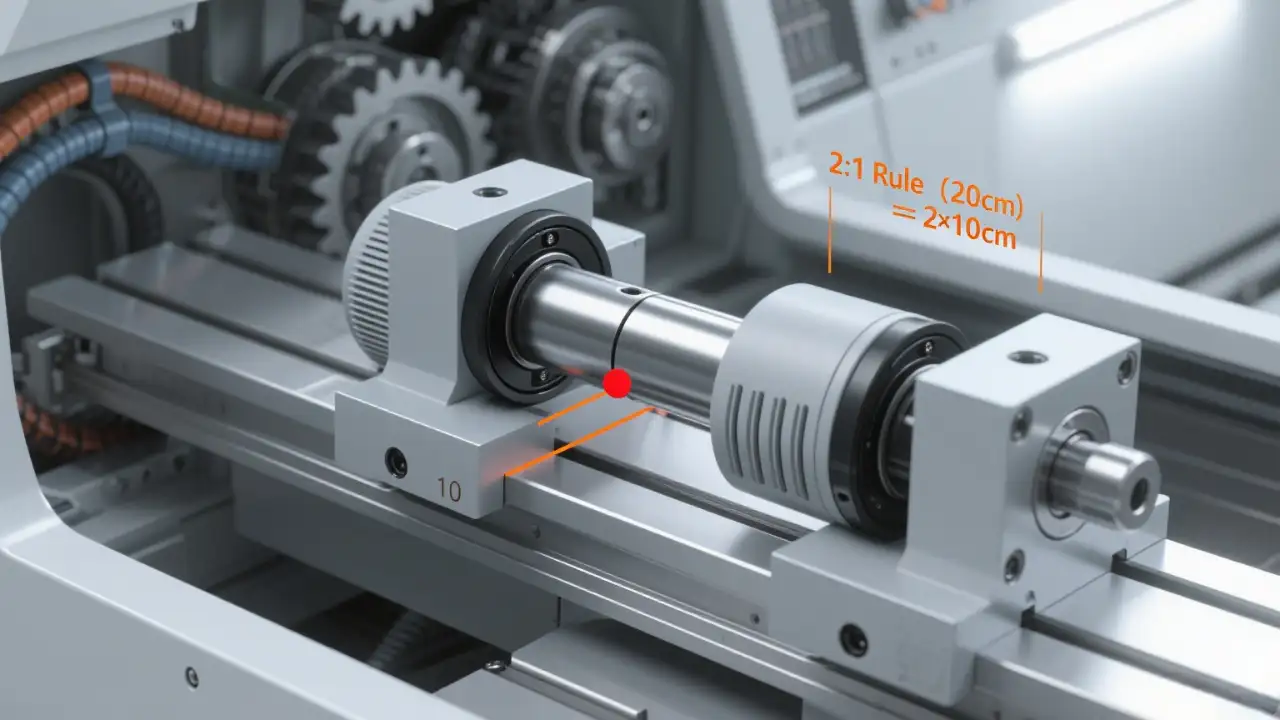

What Is the 2:1 Rule for Linear Bearings

August 04, 2025In linear motion systems, linear bearings ensure smooth, precise movement in applications like CNC machines and automated production lines. Whether designing a high-precision CNC router or troubleshooting a linear bearing rail system, proper bearing placement is critical. The 2:1 rule is a key design principle that prevents jams and keeps your linear bearing system gliding… Continue reading What Is the 2:1 Rule for Linear Bearings

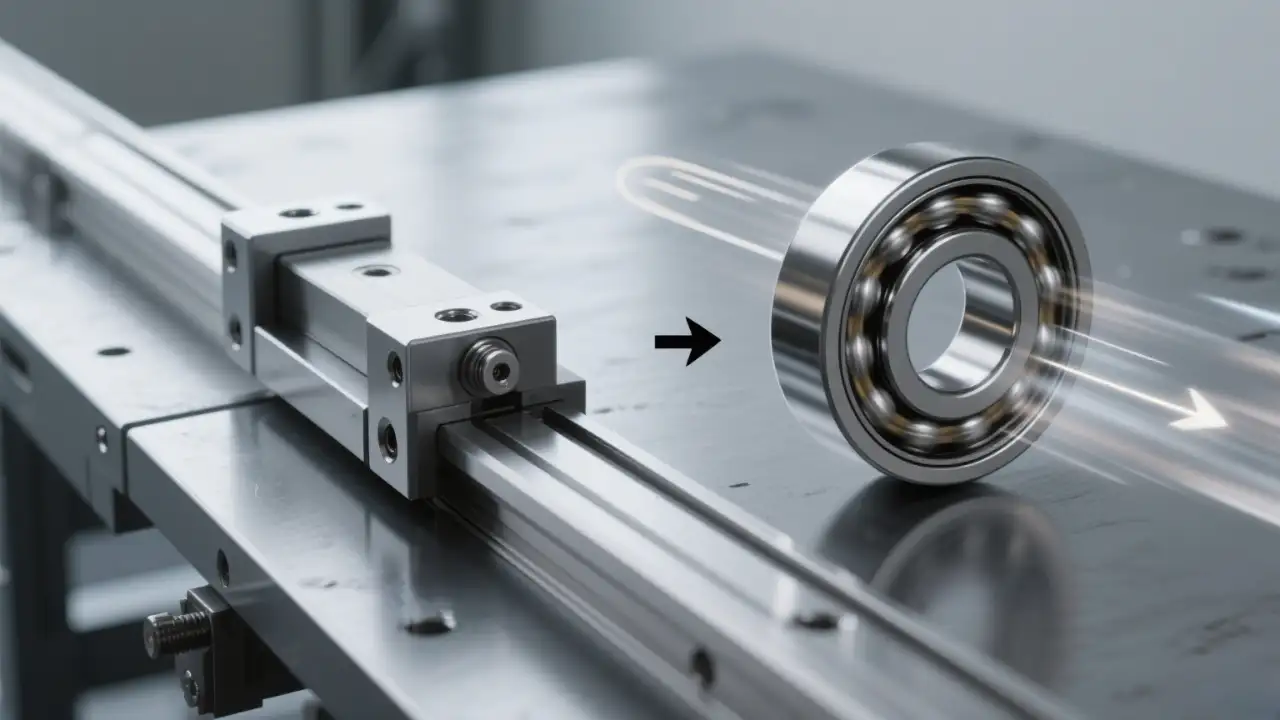

Linear Bearings Vs. Ball Bearings: Key Differences Explained

August 01, 2025Bearings are the “joints” of mechanical systems, reducing friction, supporting loads, and enabling smooth motion. From car engines to washing machines and precision factory tools, bearings enhance performance and extend equipment life. A linear bearing enables precise linear motion, like in 3D printers, while ball bearings support rotational motion, like in car hubs or electric… Continue reading Linear Bearings Vs. Ball Bearings: Key Differences Explained

Top 5 Advantages of CNC Machining for Precision Manufacturing

July 30, 2025CNC machining (Computer Numerical Control machining) transforms digital designs into high-precision parts through CNC programming, serving industries like aerospace, automotive, medical, and plastic manufacturing. With micron-level precision (1 micron = 0.001 mm), it produces complex components like aerospace turbine blades or 316 stainless steel medical implants in hours. By integrating technologies like metal injection molding,… Continue reading Top 5 Advantages of CNC Machining for Precision Manufacturing

Why Are CNC Milling Machines so Expensive? A Deep Dive into High Costs

July 28, 2025CNC milling machines are essential tools in industries like aerospace, automotive, and medical manufacturing, thanks to their accuracy, automation, and versatility. However, their price—often ranging from tens of thousands to several million dollars—can seem steep. So, what makes these machines so expensive? This article explores the four primary factors behind the high cost of CNC… Continue reading Why Are CNC Milling Machines so Expensive? A Deep Dive into High Costs

Custom CNC Machining: Definition, Advantages, And Applications

July 25, 2025Custom CNC (Computer Numerical Control) machining uses precise computer control to create tailored parts with high accuracy and complex shapes. Industries like aerospace, medical, and automotive rely on it for prototyping, small-batch production, and unique designs. It delivers micron-level precision, supports diverse materials, and enables rapid iterations. Though initial costs and skill requirements are high,… Continue reading Custom CNC Machining: Definition, Advantages, And Applications

CNC Machine Maintenance: Daily, Monthly, Annual Tips

July 23, 2025CNC machines are vital for modern manufacturing, offering precision and efficiency. A structured maintenance plan ensures consistent performance, extends equipment lifespan, and prevents costly downtime. Dedicate 10-15 minutes daily, 1-1.5 hours monthly, and 2-3 hours annually to keep your CNC machines running smoothly. 1. Daily Maintenance: Ensure Peak Performance Daily tasks prevent wear and maintain… Continue reading CNC Machine Maintenance: Daily, Monthly, Annual Tips

Linear Motion Systems: How Bearings & Rails Enable Precision Engineering

July 21, 2025A linear bearing is the unsung hero of modern mechanical engineering, gliding like a virtuoso skater to guide objects along a straight path with minimal friction. Whether it’s keeping the spindle assembly humming smoothly in a CNC router or ensuring a 3D printer’s print head hits micron-level precision, linear bearings work their magic behind the… Continue reading Linear Motion Systems: How Bearings & Rails Enable Precision Engineering

CNC Machines vs. 3D Printers: Are They the Same?

July 18, 2025CNC (Computer Numerical Control) machines and 3D printers represent two pillars of modern manufacturing, yet they operate on fundamentally different principles. CNC machines use subtractive manufacturing—removing material to achieve precise shapes—while 3D printers rely on additive manufacturing, building objects layer by layer. This article explores their definitions, technologies, applications, and how they complement each other… Continue reading CNC Machines vs. 3D Printers: Are They the Same?

Five Common Modern CNC Control Systems: High-Precision Machining Solutions

July 17, 2025Fanuc Control Systems Fanuc control systems are global leaders in CNC (Computer Numerical Control) machining, with the Japanese company Fanuc becoming almost synonymous with CNC machine tools. Renowned for their high reliability, strong compatibility, and user-friendly interface, these systems are widely adapted for various equipment, from lathes to five-axis machining centers. Their core function lies… Continue reading Five Common Modern CNC Control Systems: High-Precision Machining Solutions

Types of CNC Machines: Classification by Process, Axis & Applications

July 16, 2025CNC (Computer Numerical Control) technology is a cornerstone of modern manufacturing. By precisely controlling machine tools with digital instructions, it has revolutionized industries such as automotive, aerospace, and medical. This technology significantly enhances efficiency and accuracy, making it easy to produce complex parts. Different types of CNC machines are designed to meet specific material and… Continue reading Types of CNC Machines: Classification by Process, Axis & Applications