Blog

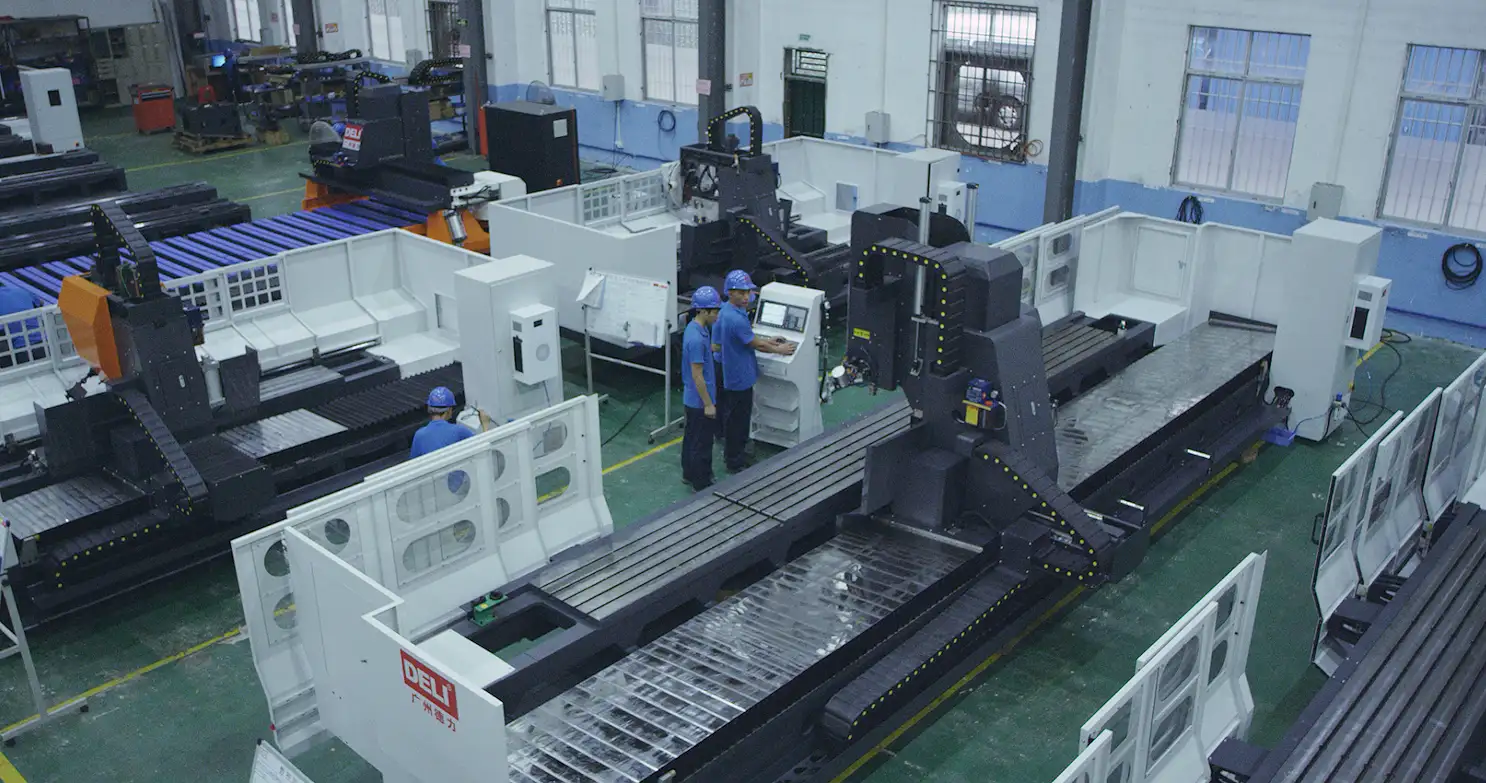

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

CNC Turning Vs. Grinding: Precision and Efficiency Comparison

August 25, 2025In modern precision manufacturing, CNC turning and grinding are essential machining processes, widely used in CNC turning services and CNC grinding equipment. Each offers unique strengths in machining precision, efficiency, and applications, making it vital to understand the differences between CNC turning and grinding to optimize processes, improve CNC turned parts quality, and reduce costs.… Continue reading CNC Turning Vs. Grinding: Precision and Efficiency Comparison

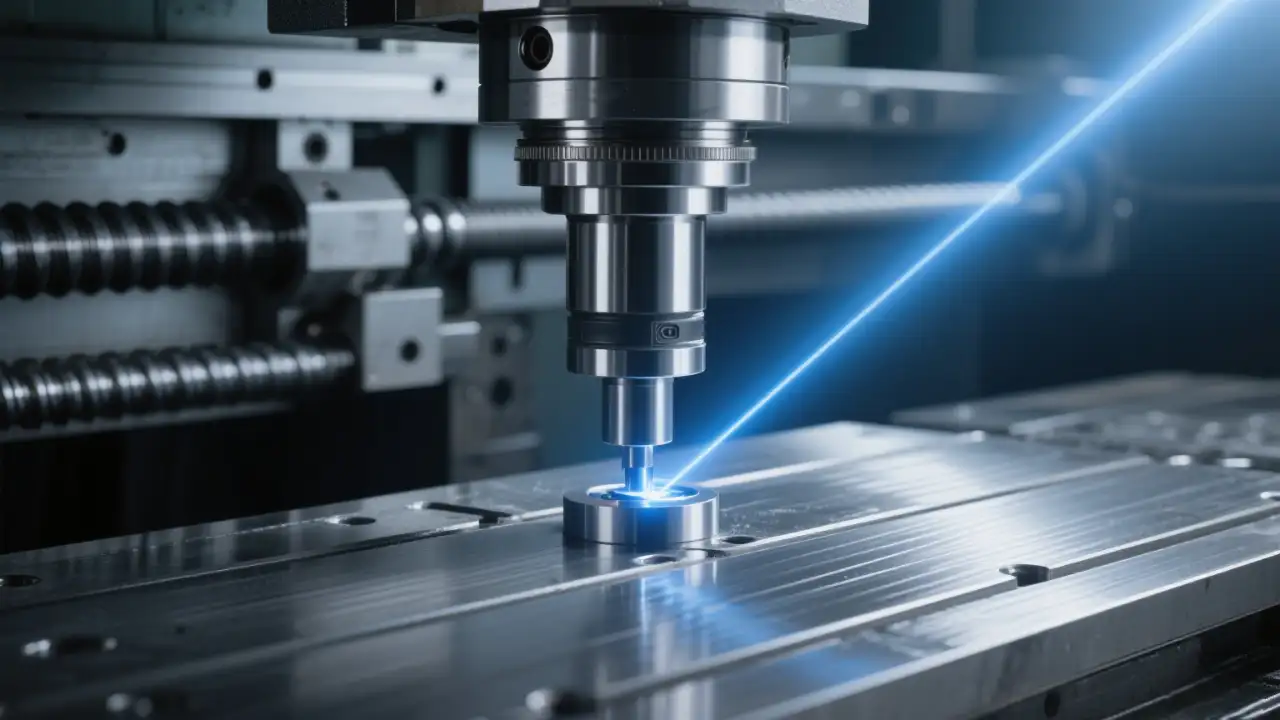

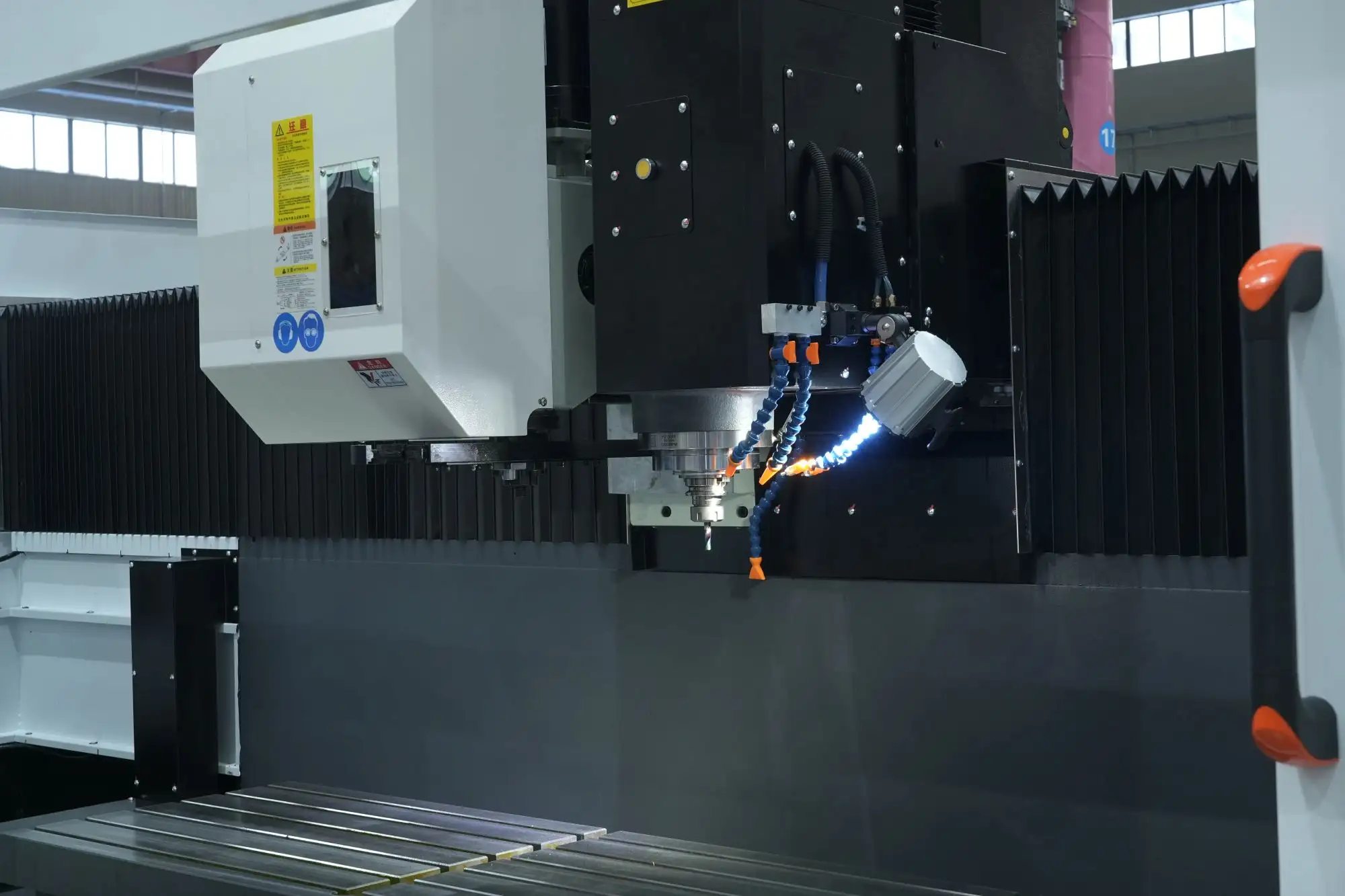

CNC Milling Machine Performance Optimization Guide

August 25, 2025In modern manufacturing, the CNC Milling Machine is a core piece of equipment, widely applied in aerospace, mold manufacturing, automotive parts, and precision electronics. In scenarios involving complex processes such as laser beam welding, or requiring collaboration with CNC Machining Centers and CNC Vertical Machining Centers, its performance directly determines machining accuracy, surface quality, and… Continue reading CNC Milling Machine Performance Optimization Guide

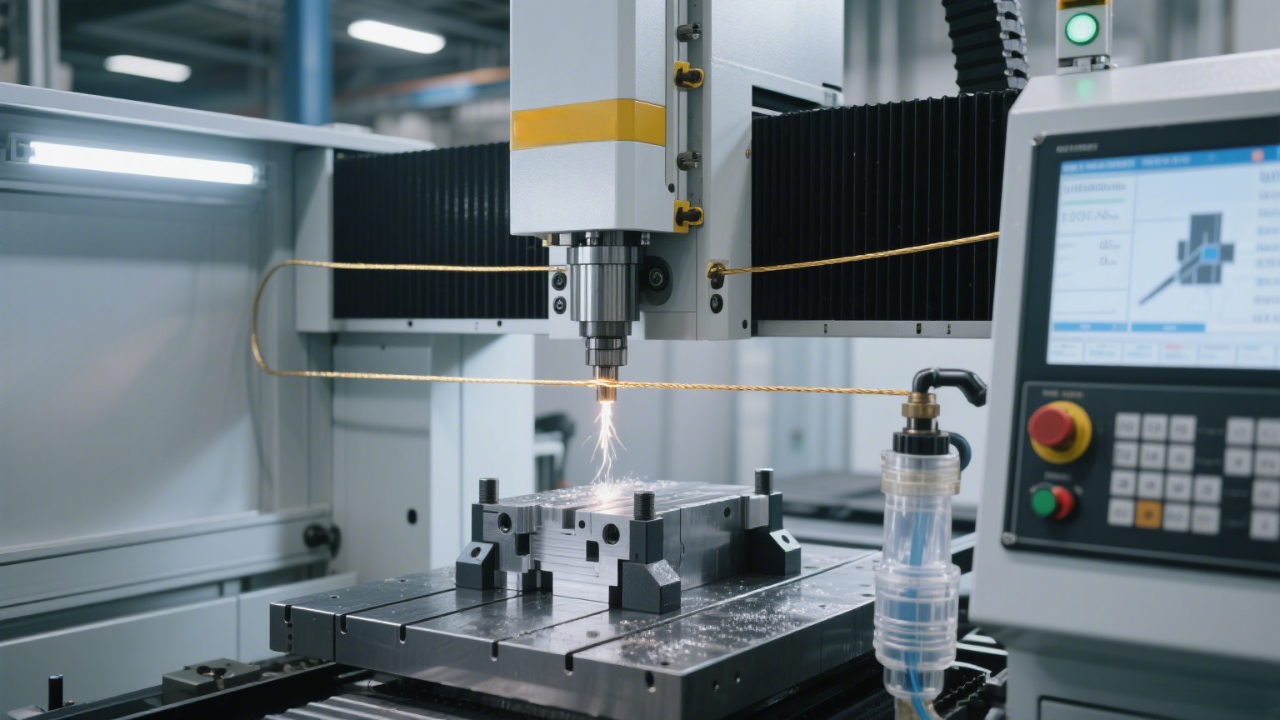

What Is EDM Wire Cutting

August 22, 2025Understanding Wire EDM Wire Electrical Discharge Machining (Wire EDM, or WEDM) is a cutting-edge manufacturing process that uses electrical sparks to slice through metal with incredible precision. Think of it as a high-tech scalpel for metal, capable of crafting intricate shapes with tolerances as tight as a few microns. It’s a go-to method for industries… Continue reading What Is EDM Wire Cutting

What Is a CNC Grinder

August 22, 2025A CNC grinder is a cornerstone of modern manufacturing, harnessing computer numerical control (CNC) technology to spin a grinding wheel at blazing speeds, delivering ultra-smooth surfaces on materials like metal, ceramics, or tough plastics with pinpoint, micron-level precision. Think of it as a digital craftsman, sculpting flawless finishes for critical components in industries like aerospace,… Continue reading What Is a CNC Grinder

G Code and M Code: The Backbone of CNC Programming

August 21, 2025G code and M code are the cornerstones of CNC (Computer Numerical Control) programming, orchestrating tool movements and auxiliary functions to deliver precision and efficiency in machining. From CNC Machining Centers to specialized equipment like Aluminum Profile CNC Machines, these codes underpin every operation. This article explores their roles, differences, and synergy, with optimized keyword… Continue reading G Code and M Code: The Backbone of CNC Programming

Metal CNC Machines: Techniques, Applications, And Selection Tips

August 20, 2025MMetal CNC Machines harness Computer Numerical Control (CNC) technology to craft precision components, transforming industries like aerospace, automotive, medical, and electronics. These CNC machines deliver micron-level tolerances, automate workflows, and tackle complex geometries. For example, aerospace turbine blades achieve tolerances of ±0.005 mm, automotive CNC lathes cut material waste by 15%, and electronics enclosures maintain… Continue reading Metal CNC Machines: Techniques, Applications, And Selection Tips

What Can CNC Machines Do? Uses and Benefits in 2025

August 20, 2025Computer Numerical Control (CNC) machines are transforming modern manufacturing with their precision and versatility. These computer-driven systems, powered by advanced CAD/CAM software, masterfully cut, engrave, and shape materials like metal, wood, plastic, and composites using optimized toolpaths and multi-axis operations. From crafting intricate industrial components to sculpting artistic masterpieces, CNC machines unlock endless possibilities with… Continue reading What Can CNC Machines Do? Uses and Benefits in 2025

Pick the Best CNC Machine Tools: Expert Tips for Smart Choices

August 19, 2025The newly bought CNC Machining Center keeps letting you down: when machining aluminum, the Aluminum Profile CNC Machine wastes a lot of power; when you want to take on precision orders, the high-precision CNC equipment can’t keep up with the tolerances. Choosing CNC machine tools is never as simple as just checking parameters. It has… Continue reading Pick the Best CNC Machine Tools: Expert Tips for Smart Choices

Choosing the right CNC equipment for automotive parts processing

August 18, 2025Choosing the right automotive parts processing equipment is crucial for achieving precision, efficiency, and cost-effectiveness in automotive manufacturing. From micrometer-level tolerances in engine blocks to intricate gear profiles in transmissions, CNC machines are indispensable for meeting diverse production needs. This guide offers a comprehensive framework for CNC equipment selection, covering needs assessment, equipment types, key… Continue reading Choosing the right CNC equipment for automotive parts processing

Quality Inspection for High-Precision CNC Machining: Tools and Techniques Explored

August 15, 2025High-precision CNC machining is a cornerstone of modern manufacturing, delivering micron-level accuracy to meet the stringent demands of industries like aerospace, medical devices, and automotive. However, achieving such precision is challenging, and robust quality inspection is essential to ensure parts meet design specifications. This article examines high-precision CNC machining quality inspection through six key aspects:… Continue reading Quality Inspection for High-Precision CNC Machining: Tools and Techniques Explored

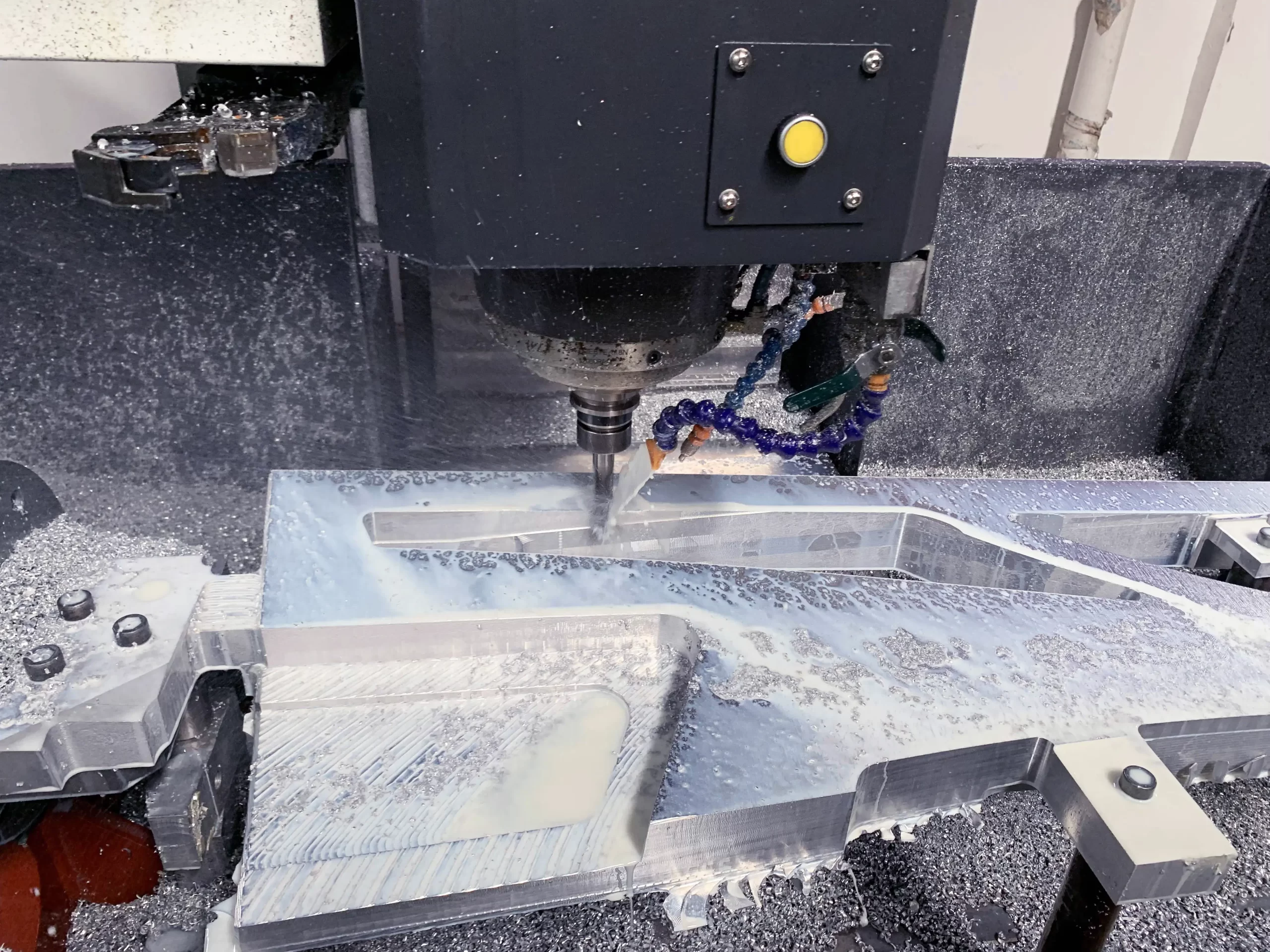

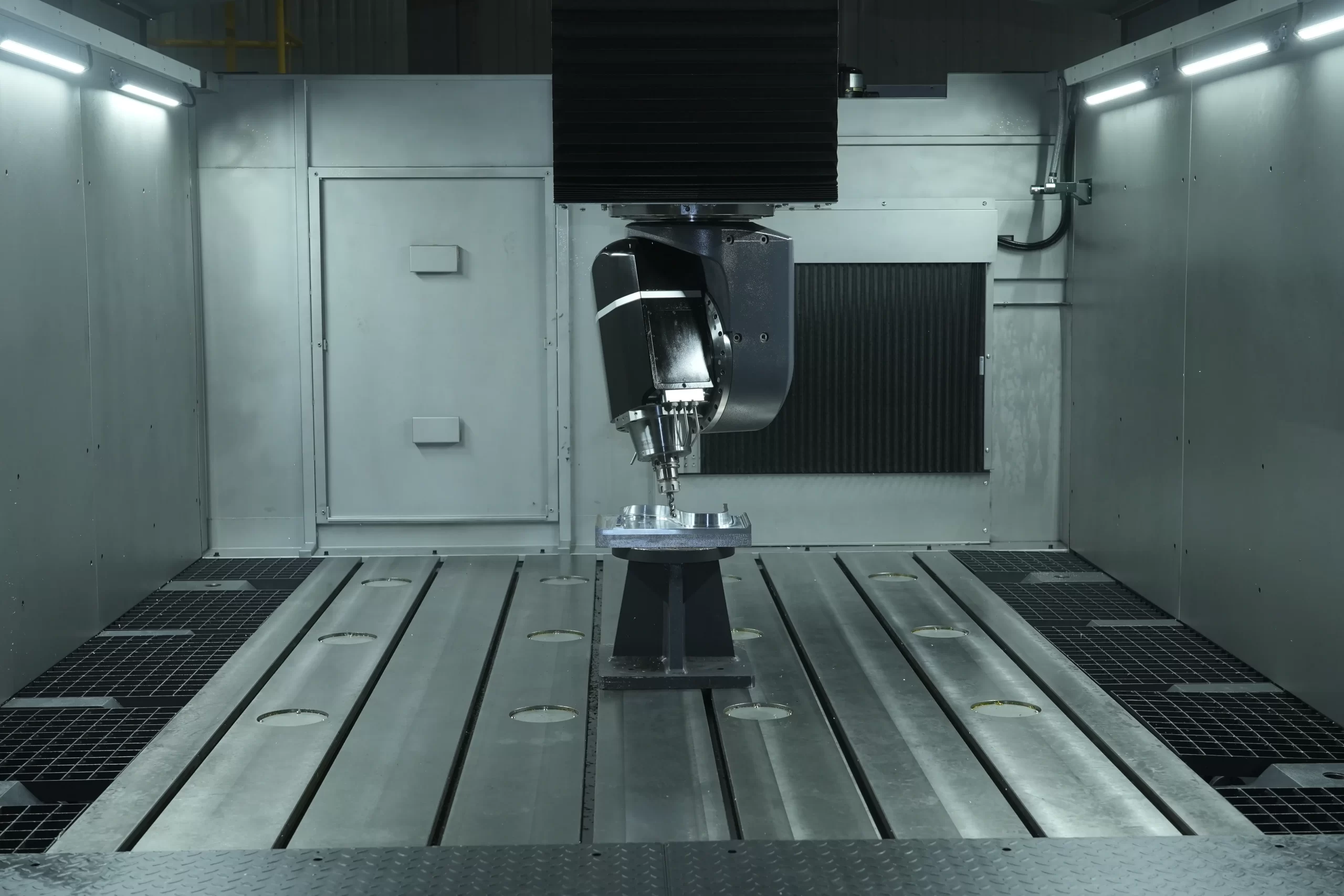

CNC Machining Equipment: Boosting Efficiency in Complex Part Production

August 13, 2025Complex surface parts, such as turbine blades and automotive molds, pose significant challenges for CNC machining equipment due to their non-planar geometries and stringent precision requirements. This guide provides a detailed roadmap for leveraging CNC machining centers to achieve high-efficiency production of such parts, covering part characteristics, advantages of high-precision CNC equipment, optimization of CNC… Continue reading CNC Machining Equipment: Boosting Efficiency in Complex Part Production

5 Common Types of CNC Machines

August 11, 2025Hey manufacturing enthusiasts! Let’s dive into the world of CNC machines, the rockstars of modern production. Powered by CNC machining technology, these machines craft everything from smartphone components to jet engine parts with jaw-dropping, micron-level precision. In this guide, we’ll explore five common types of CNC machines, highlighting their roles in high-precision CNC processing equipment… Continue reading 5 Common Types of CNC Machines