Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

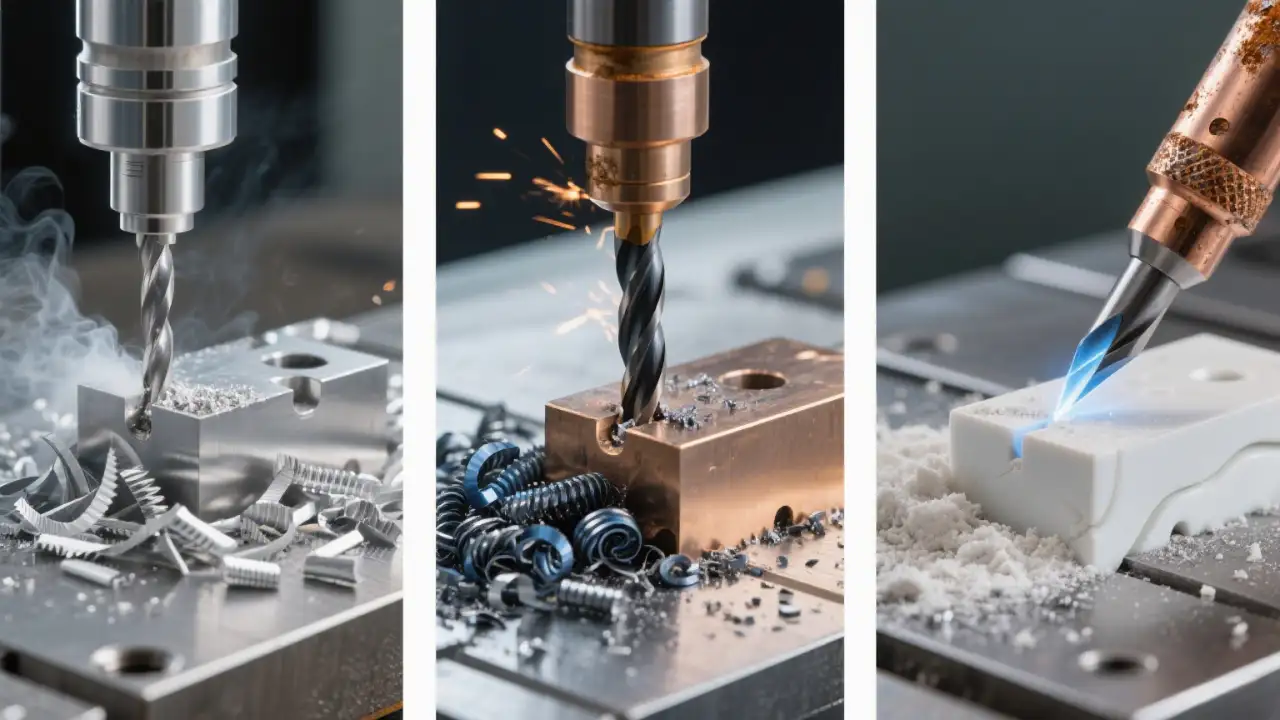

CNC Machining Materials Guide: Aluminum, Steel or Plastic

September 09, 2025In modern precision manufacturing, CNC machining has evolved from a simple “cutting process” into a fully integrated system of material selection, machining strategy, and design optimization. Choosing the wrong material can lead to cost overruns, rework, or even mass scrap and safety incidents. This guide focuses on three major categories of CNC machining materials —… Continue reading CNC Machining Materials Guide: Aluminum, Steel or Plastic

Avoid CNC Router Regret: Why 87% of Small Shops Get It Wrong

September 08, 2025“We spent $28,000 on an ‘industrial-grade’ CNC router — only to land three jobs in the first year. The machine gathered dust while loan payments choked us.”— Master Chen, owner of a woodworking studio in Zhejiang This isn’t an isolated case. Across the globe, small manufacturing shops, woodworkers, signage studios, and prototyping labs are falling… Continue reading Avoid CNC Router Regret: Why 87% of Small Shops Get It Wrong

CNC Machining Center Automation: How Tool Magazines & ATC Systems Boost Productivity

September 05, 20251. The Foundation of CNC Machining Center Automation 1.1 Core Capabilities and Automation Hierarchy A CNC machining center is a high-precision metal-cutting machine equipped with a spindle system, multi-axis motion, numerical control, and crucially—a tool magazine and automatic tool changer (ATC). These features allow it to perform milling, drilling, tapping, boring, and other operations in… Continue reading CNC Machining Center Automation: How Tool Magazines & ATC Systems Boost Productivity

How to Prevent CNC Machine Coolant from Going Bad: Causes & Fixes

September 05, 2025In modern metal cutting manufacturing, cnc machine coolant plays a critical role in maintaining machining precision, extending tool life, and ensuring equipment stability. In high-load, continuous operations on metal CNC machines, including CNC milling machines, CNC lathes, and 5-axis CNC machines, the coolant is constantly exposed to high temperatures, humidity, and contamination from metal ions—conditions… Continue reading How to Prevent CNC Machine Coolant from Going Bad: Causes & Fixes

CNC Machining vs. Manual Machining: How to Choose?

September 04, 2025In manufacturing, the choice of machining method is never trivial. Do you go with highly automated CNC machining, or rely on the seasoned hands of a skilled machinist using manual techniques? This decision doesn’t just affect part accuracy and consistency—it directly influences production efficiency, cost structure, and even your company’s competitive edge. This article breaks… Continue reading CNC Machining vs. Manual Machining: How to Choose?

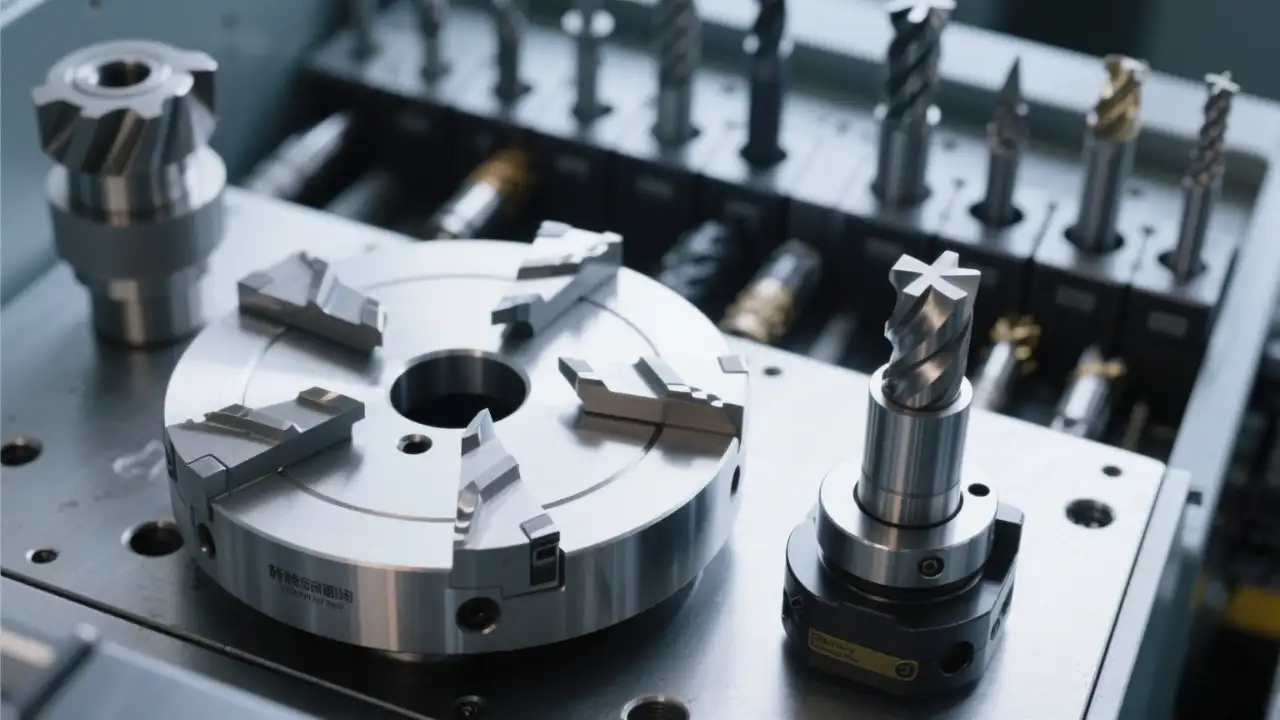

CNC machining tools: Types, Uses, Selection Tips

September 03, 2025In modern precision manufacturing, CNC machining tools serve as the core execution units of cutting processes. Their performance and compatibility directly determine machining efficiency, surface quality, and process stability. As CNC machine tools evolve toward high speed, high precision, and multi-axis compound processing, the coordinated optimization of CNC cutting tools and tool grinders has become… Continue reading CNC machining tools: Types, Uses, Selection Tips

A Comprehensive Guide to CNC Machining Parameters

September 02, 2025In modern CNC machining, selecting the right parameters is not just about speed or feed—it’s about understanding the underlying physics of cutting, material behavior, and system dynamics. From aerospace to medical devices, CNC machining drives precision manufacturing, and mastering its core parameters—cutting speed, spindle speed, feed rate, depth of cut, cooling, and toolpath—is essential for… Continue reading A Comprehensive Guide to CNC Machining Parameters

What Are the Steps in the CNC Machine Operation Process

August 29, 2025CNC machines, computer numerical control rigs, are the real deal for steering tools and parts with pinpoint accuracy via software. They slice, drill, or mill anything from steel to plastic to wood like nobodys business. Youll spot em cranking out parts in car shops, aerospace plants, even furniture joints. Operating one? You better have every… Continue reading What Are the Steps in the CNC Machine Operation Process

5 Common Mistakes Made by CNC Machine Tool Beginners

August 29, 2025CNC machines are powerful tools, but for beginners, stepping into pitfalls is almost inevitable. This article breaks down the 5 most common mistakes—from setting up workpieces to navigating the control panel—and shows you how to dodge them. Each section explains the problem, walks you through fixes, and tosses in practical tips to get you up… Continue reading 5 Common Mistakes Made by CNC Machine Tool Beginners

What Materials Can Be Machined on a Vertical Machining Center

August 27, 2025The vertical machining center stands at the heart of modern precision manufacturing, serving as a go-to solution for high-accuracy, medium-to-low volume production across industries such as aerospace, automotive, medical devices, and mold making. With its spindle oriented vertically and a compact, rigid structure, the vertical machining center excels at milling, drilling, tapping, and contouring complex… Continue reading What Materials Can Be Machined on a Vertical Machining Center

Practical Tips to Boost CNC Machining Center Efficiency

August 27, 2025In modern precision manufacturing, the CNC machining center stands as a cornerstone of production. Whether it’s a CNC Gantry Milling Machine or a CNC Profile Machining Center, its operational efficiency directly impacts production cycles, cost control, and delivery timelines. Yet, many manufacturers still grapple with common challenges: low machine utilization, long changeover times, short tool… Continue reading Practical Tips to Boost CNC Machining Center Efficiency

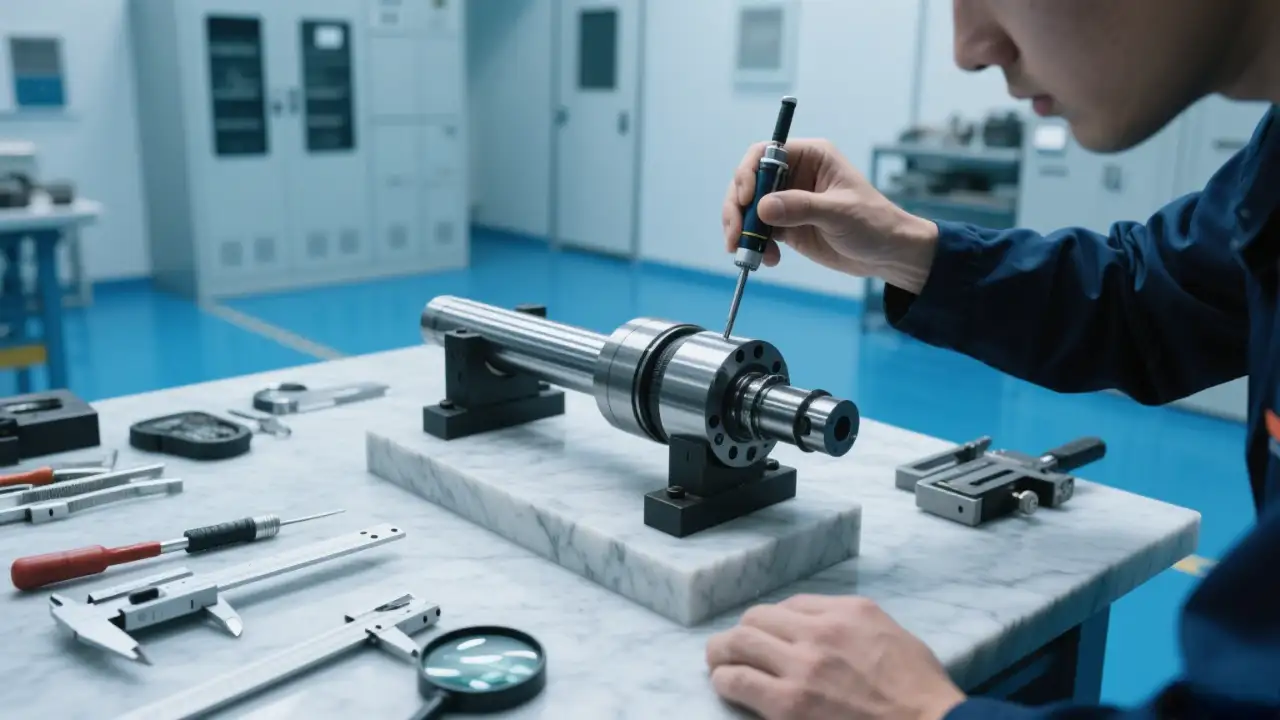

What Is the CNC Spindle Repair Process

August 26, 2025The CNC spindle is the core of a CNC machine, driving tools with high speed and stability for precise metal cutting and grinding in precision manufacturing. Wear, vibration, or faults from prolonged or improper use can reduce CNC machining quality. This article details the CNC spindle repair process, showing how professional repair restores performance and… Continue reading What Is the CNC Spindle Repair Process