Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

Top 6 Essential Machine Shop Tools Manufacturing Workshop Needs

October 09, 2025In today’s manufacturing landscape, CNC machining dominates global production output at 61%, far outpacing fabrication (22%) and welding (17%). But simply owning CNC machines isn’t enough. True competitive advantage comes from strategically equipping your workshop with the right combination of core tools, optimized parameters, and smart integration. This guide details the six indispensable machine shop… Continue reading Top 6 Essential Machine Shop Tools Manufacturing Workshop Needs

Five Key Advantages of the SCA Series CNC Milling Machining

October 06, 2025In modern manufacturing, CNC milling machining demands more than just cutting—it requires precision, power, and reliability. When you’re machining large aerospace frames, automotive transmission housings, or heavy-duty molds, you need a machine built for the toughest jobs. The SCA Series CNC Vertical Machining Center from Deli CNC delivers exactly that—combining high precision, exceptional rigidity, smart… Continue reading Five Key Advantages of the SCA Series CNC Milling Machining

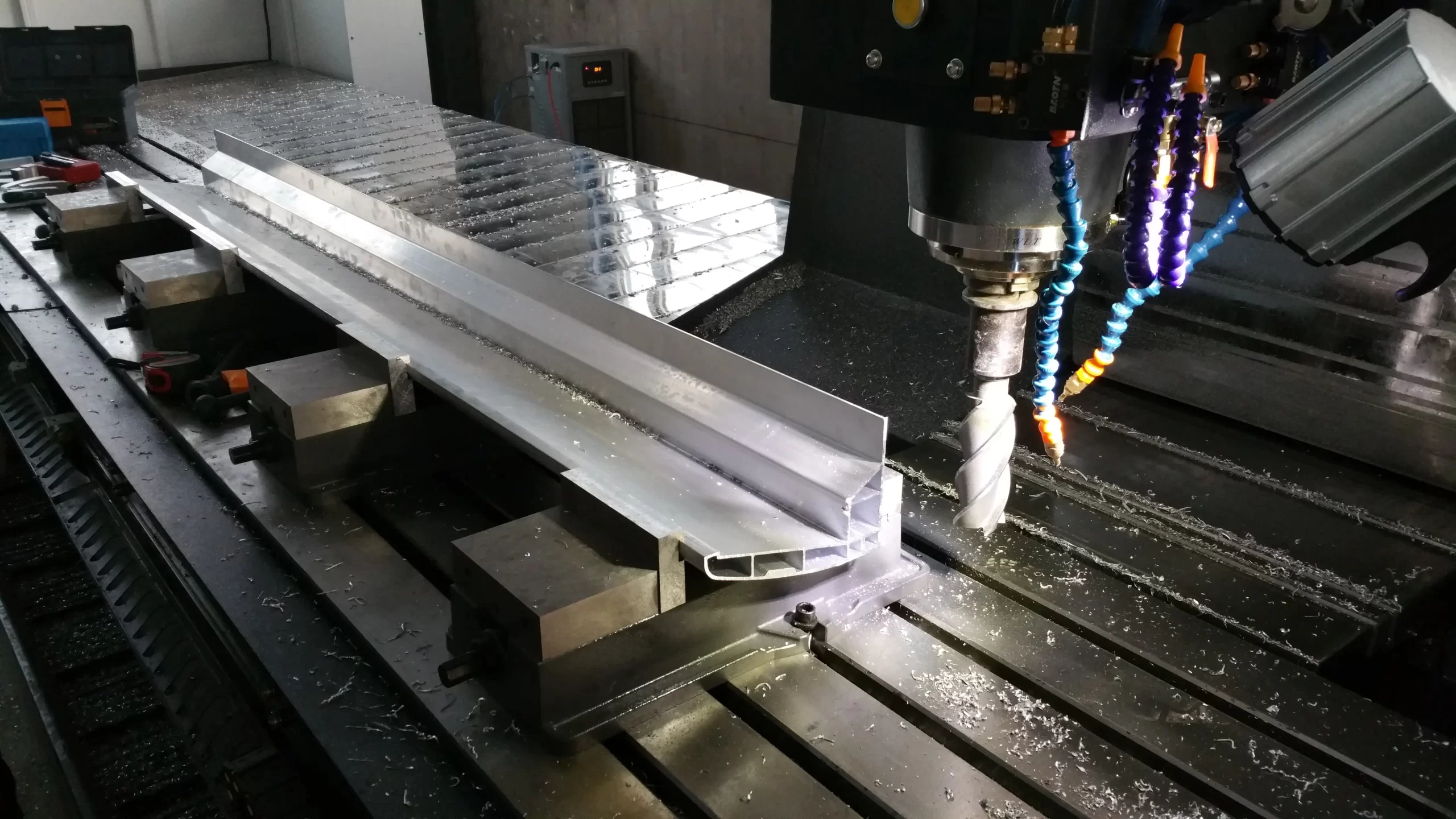

Curtain Walls and CNC Tools for Modern Design

September 29, 2025You see curtain walls shaping the look of modern buildings. They use materials like glass and aluminum to create non-structural facades that prioritize aesthetics, daylight, and energy performance. But behind every sleek facade lies a critical manufacturing challenge: precision fabrication of long, thin, hollow profiles. This is where specialized Curtain Wall CNC Fabrication Equipment—not generic… Continue reading Curtain Walls and CNC Tools for Modern Design

CNC Vertical Machining Center Structure

September 26, 20251. Introduction The CNC vertical machining center (VMC) stands as a cornerstone of modern precision manufacturing. With its spindle mounted vertically and the workpiece secured on a horizontal table, it executes complex milling, drilling, tapping, and contouring operations through coordinated X-, Y-, and Z-axis motion. Consequently, VMCs are essential across industries—from mold-making and aerospace to… Continue reading CNC Vertical Machining Center Structure

How to Choose the Right CNC Machine Producers for Your Business

September 25, 2025In over a decade of helping global manufacturers, we’ve seen too many companies pay dearly for the wrong choice. These mistakes don’t just cost money — they break delivery promises, erode customer trust, and cripple long-term competitiveness. As a leading exporter of premium CNC equipment, we know this truth better than most: Choosing a CNC… Continue reading How to Choose the Right CNC Machine Producers for Your Business

CNC Machine Cost 2025: Key Cost Drivers Every Global Buyer Must Understand

September 22, 2025Welcome to 2025 — where global manufacturing is being reshaped by smart factories, flexible production, green mandates, and supply chain resilience. These aren’t buzzwords anymore. They’re operational imperatives. At the heart of it all? The CNC machine — the “mother of all machines.” Buying one today is no longer a simple equipment purchase. It’s a… Continue reading CNC Machine Cost 2025: Key Cost Drivers Every Global Buyer Must Understand

How to Ensure the Precision of a CNC Machine Center

September 19, 20251. Introduction: Precision Is the Heartbeat of Your CNC Machine Center In today’s precision manufacturing landscape, the CNC machine center — short for Computer Numerical Control machining center — isn’t just another piece of equipment. It’s the backbone of smart factories, where micron-level accuracy can make or break product performance, safety, and profitability. Think aerospace… Continue reading How to Ensure the Precision of a CNC Machine Center

Can a Milling Machine Be Used as a Drill Press

September 19, 20251. Defining the Roles: Milling Machines vs. Drill Presses In modern metal-cutting operations, milling machine operation and drill press usage represent two fundamental, yet distinct, machining processes. Drill presses are engineered specifically for efficient, high-thrust axial drilling. In contrast, vertical milling machines are designed as versatile platforms capable of complex multi-axis contouring, slotting, facing, and… Continue reading Can a Milling Machine Be Used as a Drill Press

CNC Machine Tools: Match Tool to Material, Not Machine

September 15, 20251. The Critical Role of CNC Machine Tools as System-Critical Components In modern precision manufacturing, CNC machine tools are no longer viewed as mere platforms for material removal—they are the central execution nodes of the entire production system. While investment in high-accuracy five-axis machining centers has become commonplace, a significant proportion of facilities continue to… Continue reading CNC Machine Tools: Match Tool to Material, Not Machine

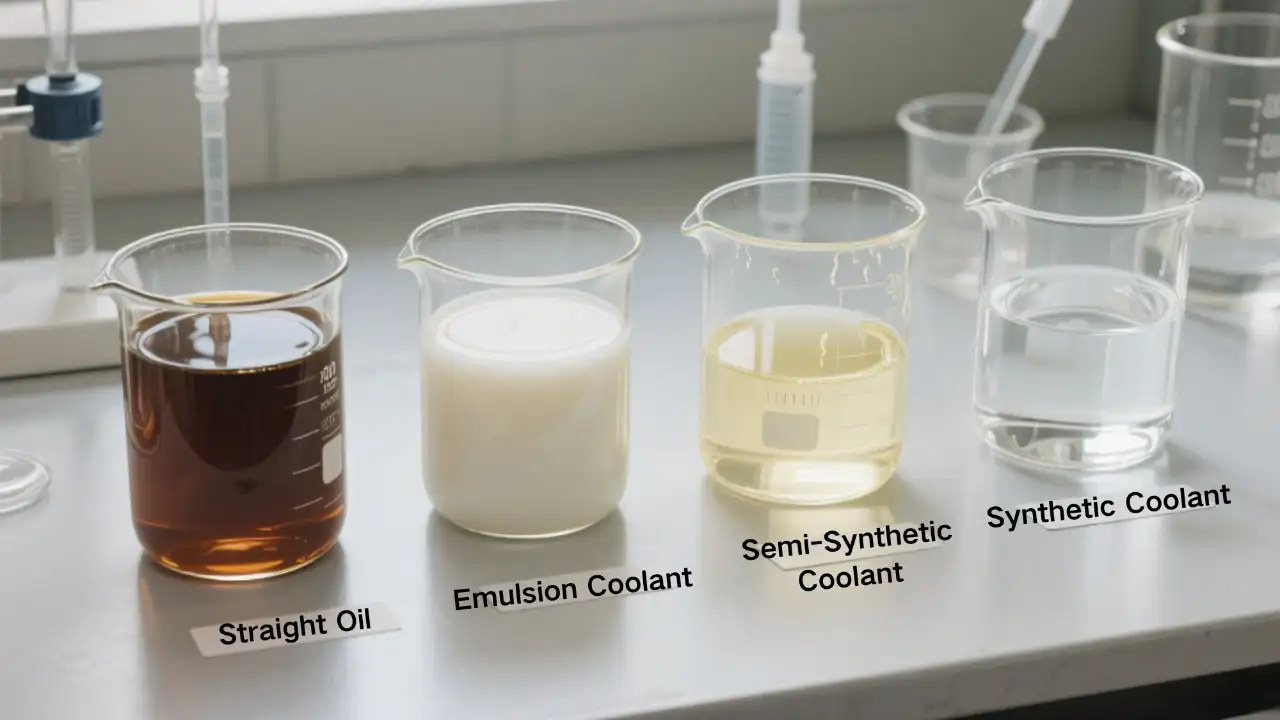

Coolant Selection in CNC Machining: Maximize Tool Life & Finish

September 12, 2025In precision manufacturing, the selection of an appropriate coolant type directly influences machining efficiency, tool longevity, and dimensional accuracy of finished components. The four principal categories — straight oils, soluble oils, semi-synthetic fluids, and fully synthetic formulations — exhibit distinct performance profiles in lubrication, heat dissipation, material compatibility, and environmental impact. This guide provides a… Continue reading Coolant Selection in CNC Machining: Maximize Tool Life & Finish

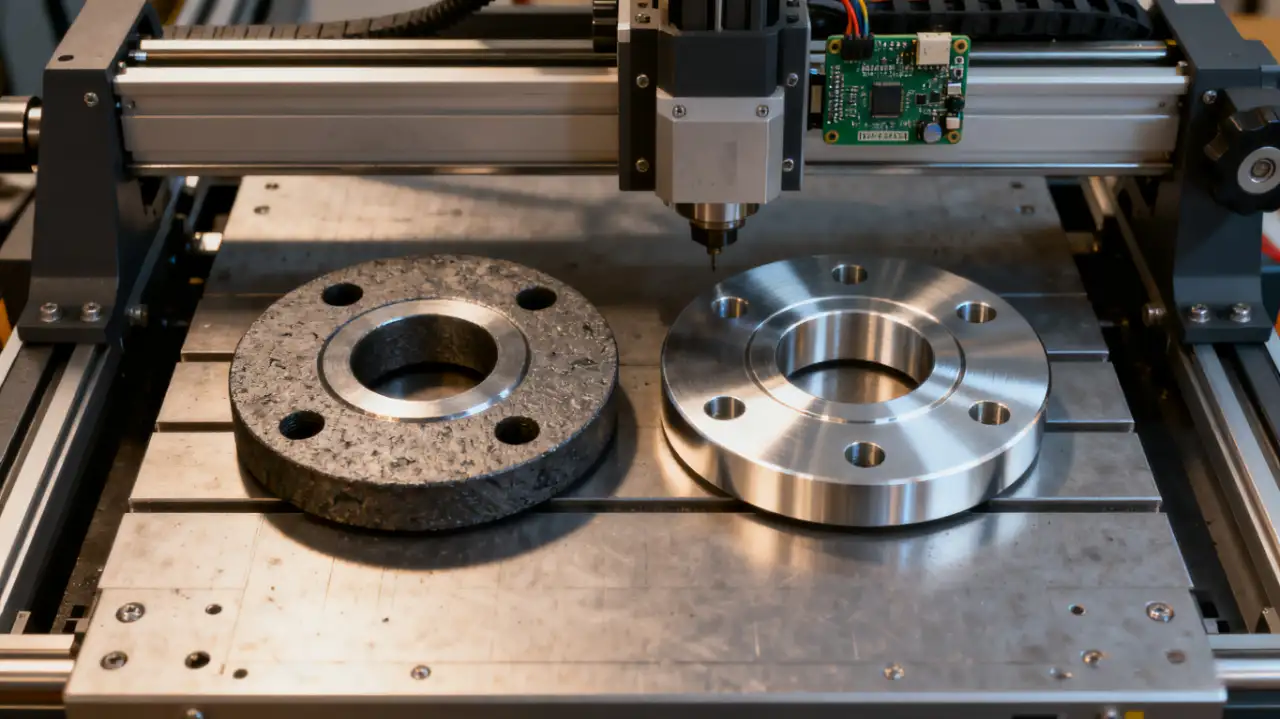

GRBL vs Precision on Your Desktop CNC Milling Machine

September 11, 2025You bought a desktop CNC mill because you wanted to make precise parts. Not “close enough.” Not “fine for wood.” You wanted tolerances within ±0.05mm. Mirror-like surface finishes. Repeatable hole patterns. Industrial-grade results — from your garage or workshop. And you started with GRBL. Because everyone does.It’s cheap. It’s simple. Plug in an Arduino, fire… Continue reading GRBL vs Precision on Your Desktop CNC Milling Machine

What Is a CNC Machinist

September 10, 2025In today’s world of smart factories and digital manufacturing, the CNC machinist stands at the powerful intersection of code and metal — turning 3D models into real-world parts with tolerances thinner than a human hair. Forget the outdated “button-pusher” stereotype. Modern CNC machinists don’t just run machines — they optimize processes, troubleshoot first-article failures, fine-tune… Continue reading What Is a CNC Machinist