Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

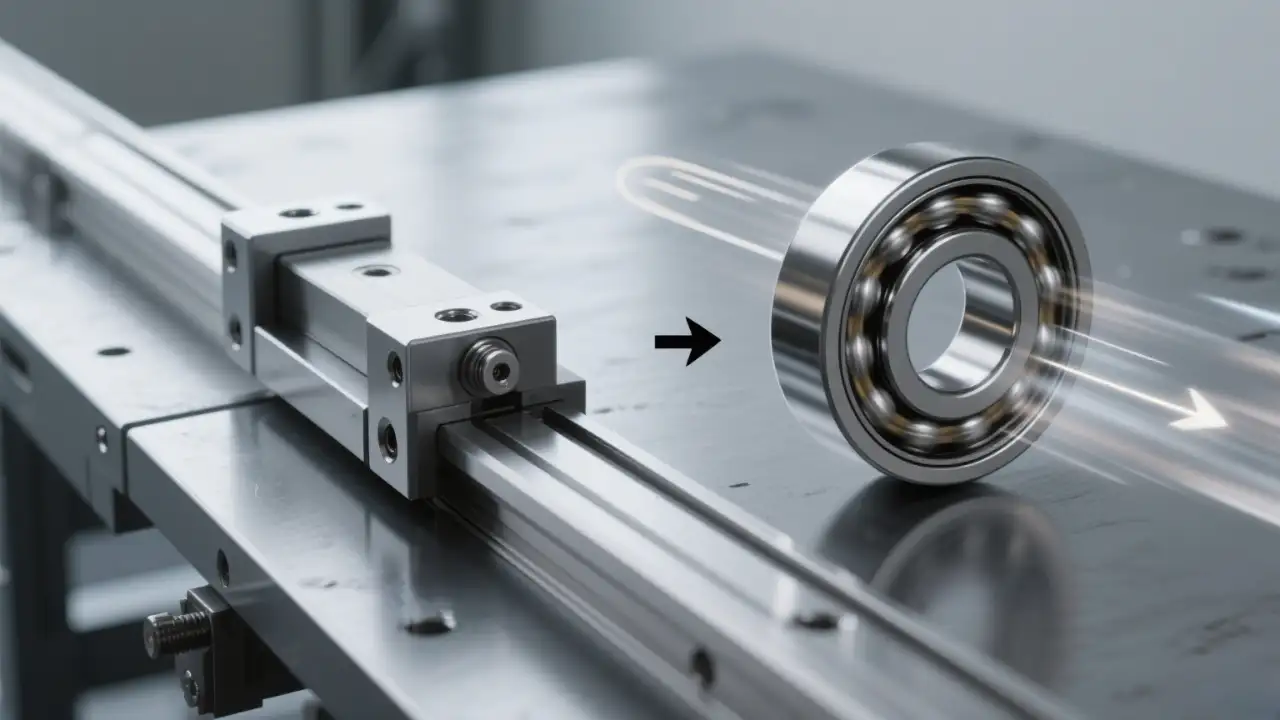

Linear Bearings Vs. Ball Bearings: Key Differences Explained

BlogBearings are the “joints” of mechanical systems, reducing friction, supporting loads, and enabling smooth motion. From car engines to washing machines and precision factory tools, bearings enhance performance and extend equipment life. A linear bearing enables precise linear motion, like in 3D printers, while ball bearings support rotational motion, like in car hubs or electric… Continue reading Linear Bearings Vs. Ball Bearings: Key Differences Explained

Top 5 Advantages of CNC Machining for Precision Manufacturing

BlogCNC machining (Computer Numerical Control machining) transforms digital designs into high-precision parts through CNC programming, serving industries like aerospace, automotive, medical, and plastic manufacturing. With micron-level precision (1 micron = 0.001 mm), it produces complex components like aerospace turbine blades or 316 stainless steel medical implants in hours. By integrating technologies like metal injection molding,… Continue reading Top 5 Advantages of CNC Machining for Precision Manufacturing

Why Are CNC Milling Machines so Expensive? A Deep Dive into High Costs

BlogCNC milling machines are essential tools in industries like aerospace, automotive, and medical manufacturing, thanks to their accuracy, automation, and versatility. However, their price—often ranging from tens of thousands to several million dollars—can seem steep. So, what makes these machines so expensive? This article explores the four primary factors behind the high cost of CNC… Continue reading Why Are CNC Milling Machines so Expensive? A Deep Dive into High Costs