Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

The Ultimate Guide to Choosing the Best CNC Machining Centers in 2025

Blog1. Why Choosing the Right CNC Machining Center Matters CNC machining centers (Computer Numerical Control equipment) are the backbone of modern manufacturing, powering industries like automotive, aerospace, renewable energy, rail transport, and 5G electronics with precision and efficiency. Picking the right machine isn’t just about buying equipment—it directly impacts productivity, cost management, and product quality.… Continue reading The Ultimate Guide to Choosing the Best CNC Machining Centers in 2025

10 Practical Tips to Improve CNC Machining Efficiency

BlogCNC machining powers modern manufacturing. Improving CNC machining efficiency slashes costs, speeds up delivery, and sharpens your competitive edge. This guide shares 10 practical tips, from refining tool paths to leveraging simulation software, to elevate your process. Start optimizing now! Tip 1: Boost CNC Machining Efficiency with Tool Path Optimization Advanced CAM software like Mastercam… Continue reading 10 Practical Tips to Improve CNC Machining Efficiency

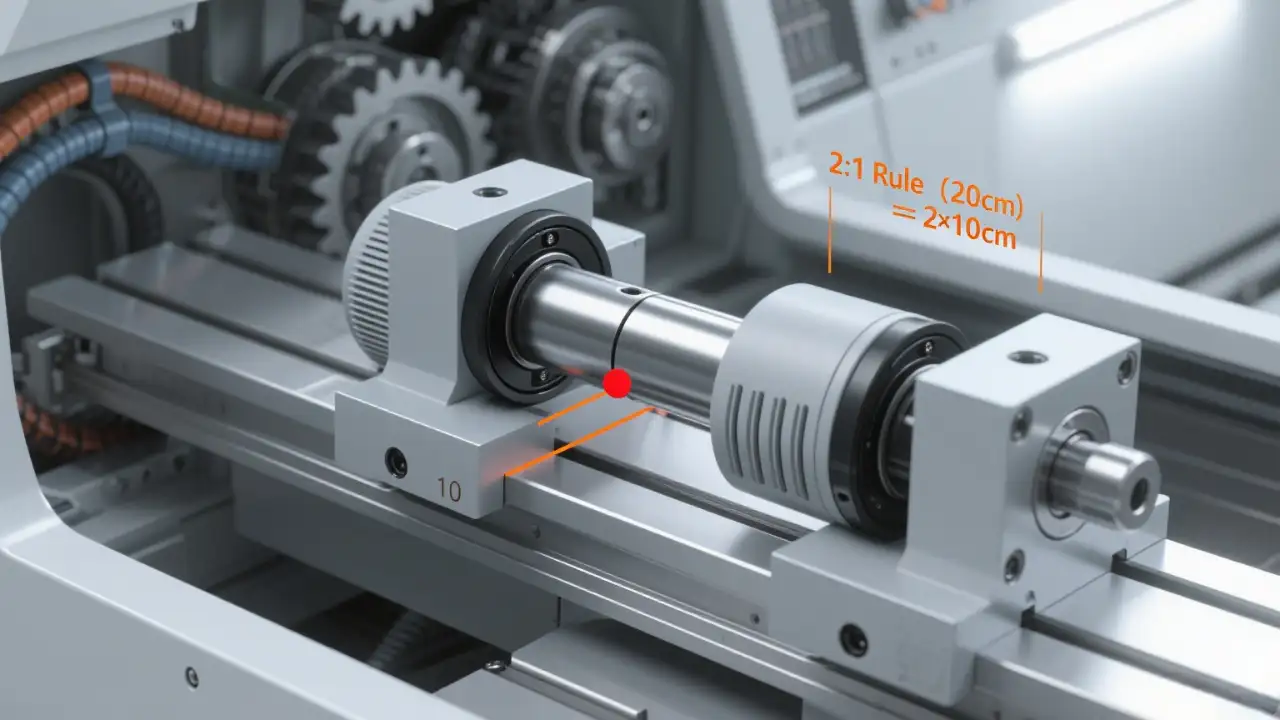

What Is the 2:1 Rule for Linear Bearings

BlogIn linear motion systems, linear bearings ensure smooth, precise movement in applications like CNC machines and automated production lines. Whether designing a high-precision CNC router or troubleshooting a linear bearing rail system, proper bearing placement is critical. The 2:1 rule is a key design principle that prevents jams and keeps your linear bearing system gliding… Continue reading What Is the 2:1 Rule for Linear Bearings