Blog

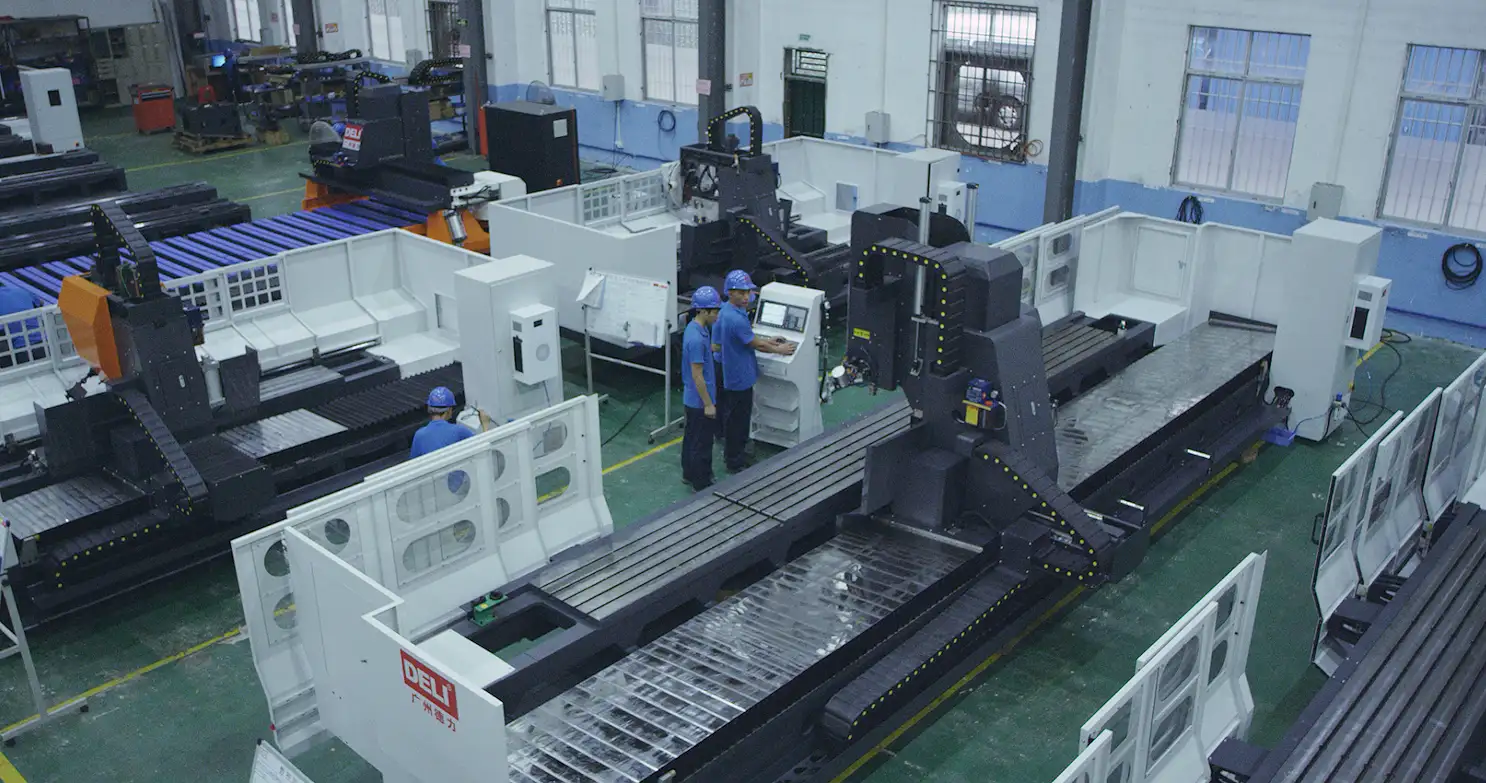

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

Choosing the right CNC equipment for automotive parts processing

BlogChoosing the right automotive parts processing equipment is crucial for achieving precision, efficiency, and cost-effectiveness in automotive manufacturing. From micrometer-level tolerances in engine blocks to intricate gear profiles in transmissions, CNC machines are indispensable for meeting diverse production needs. This guide offers a comprehensive framework for CNC equipment selection, covering needs assessment, equipment types, key… Continue reading Choosing the right CNC equipment for automotive parts processing

Quality Inspection for High-Precision CNC Machining: Tools and Techniques Explored

BlogHigh-precision CNC machining is a cornerstone of modern manufacturing, delivering micron-level accuracy to meet the stringent demands of industries like aerospace, medical devices, and automotive. However, achieving such precision is challenging, and robust quality inspection is essential to ensure parts meet design specifications. This article examines high-precision CNC machining quality inspection through six key aspects:… Continue reading Quality Inspection for High-Precision CNC Machining: Tools and Techniques Explored

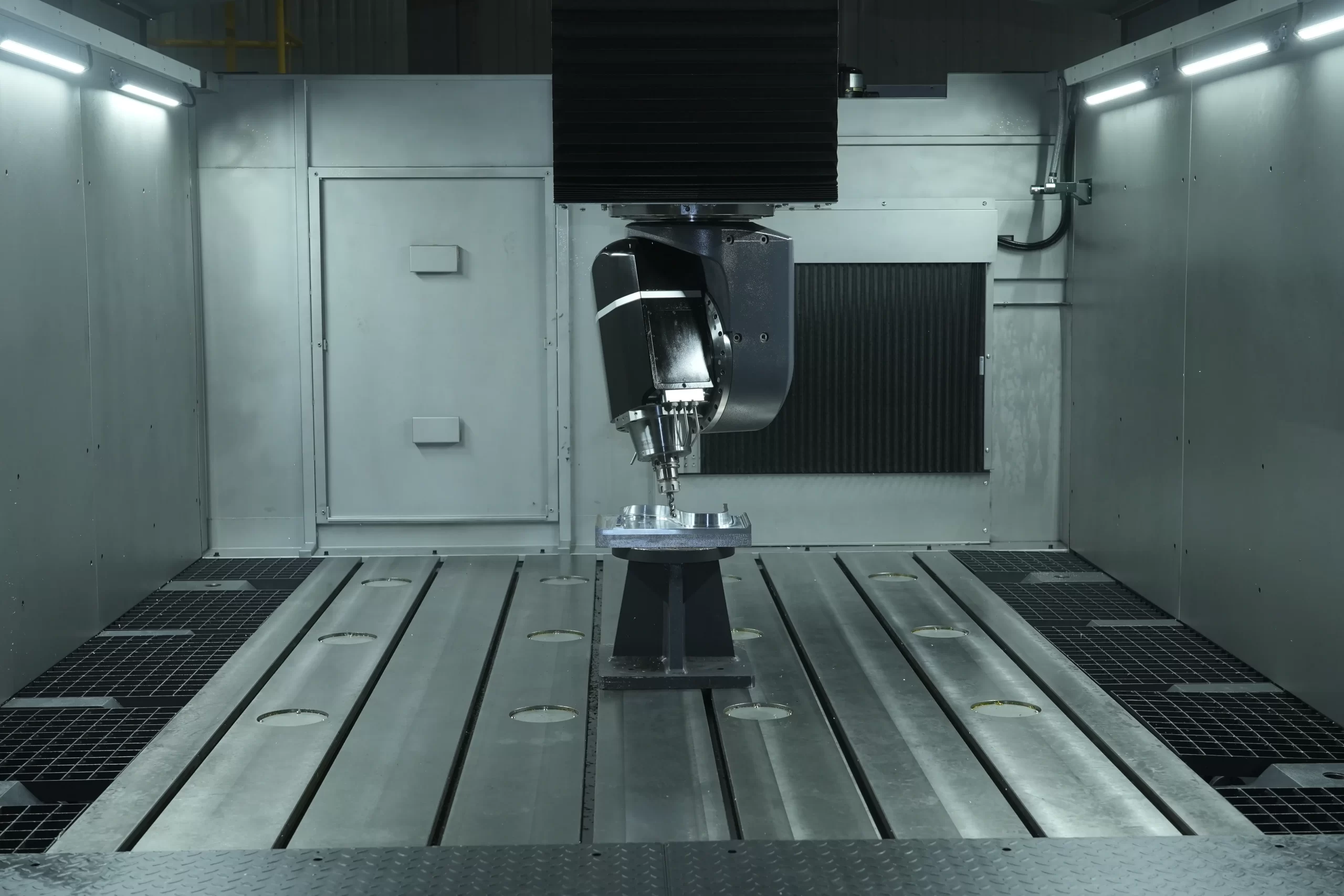

CNC Machining Equipment: Boosting Efficiency in Complex Part Production

BlogComplex surface parts, such as turbine blades and automotive molds, pose significant challenges for CNC machining equipment due to their non-planar geometries and stringent precision requirements. This guide provides a detailed roadmap for leveraging CNC machining centers to achieve high-efficiency production of such parts, covering part characteristics, advantages of high-precision CNC equipment, optimization of CNC… Continue reading CNC Machining Equipment: Boosting Efficiency in Complex Part Production