Blog

Deli QualityDeli CNC adheres to the business philosophy of “virtue and kindness, strength and quality”, always adheres to the quality standards of “high precision, efficiency and stability”, takes technology as the core, and unswervingly follows the road of technological innovation.

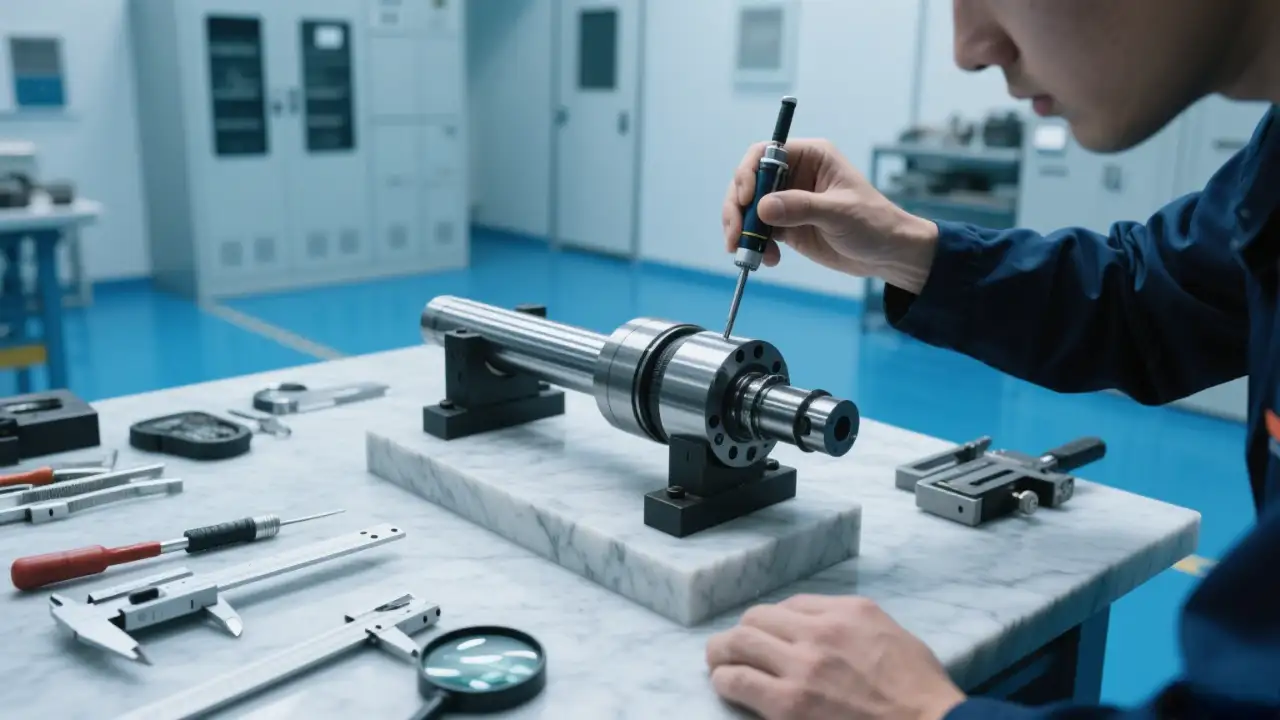

What Is the CNC Spindle Repair Process

BlogThe CNC spindle is the core of a CNC machine, driving tools with high speed and stability for precise metal cutting and grinding in precision manufacturing. Wear, vibration, or faults from prolonged or improper use can reduce CNC machining quality. This article details the CNC spindle repair process, showing how professional repair restores performance and… Continue reading What Is the CNC Spindle Repair Process

CNC Turning Vs. Grinding: Precision and Efficiency Comparison

BlogIn modern precision manufacturing, CNC turning and grinding are essential machining processes, widely used in CNC turning services and CNC grinding equipment. Each offers unique strengths in machining precision, efficiency, and applications, making it vital to understand the differences between CNC turning and grinding to optimize processes, improve CNC turned parts quality, and reduce costs.… Continue reading CNC Turning Vs. Grinding: Precision and Efficiency Comparison

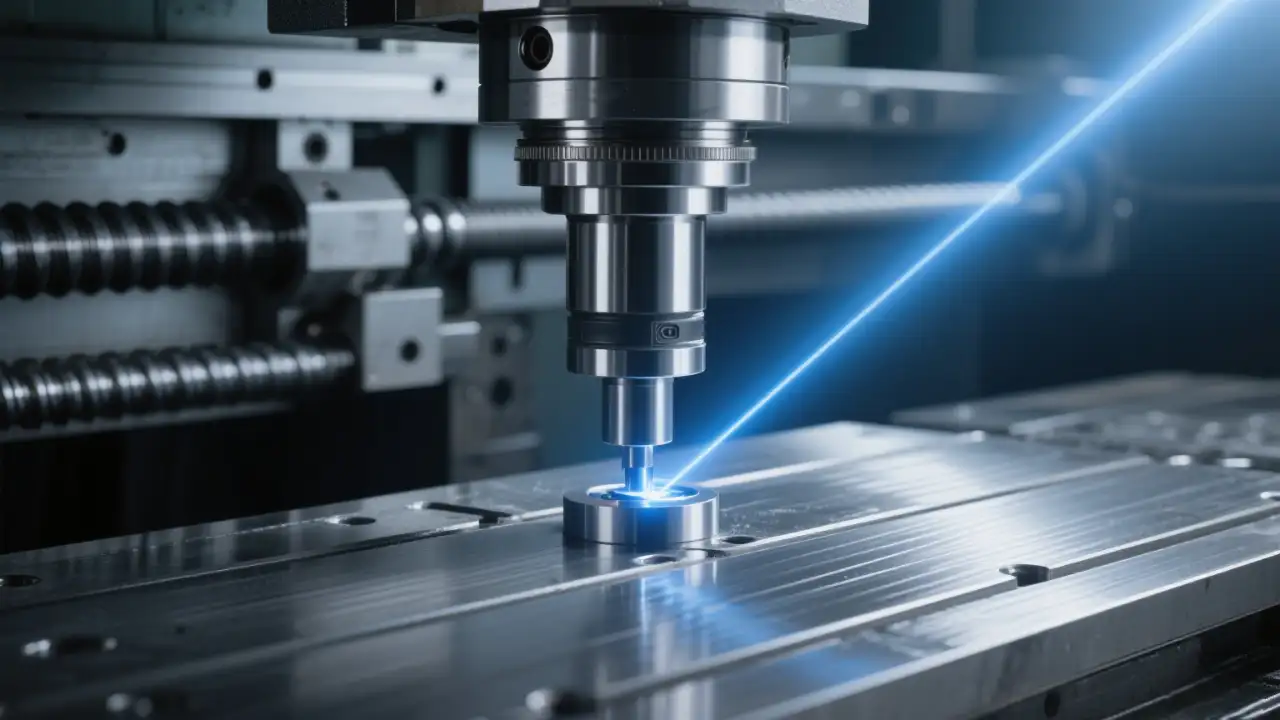

CNC Milling Machine Performance Optimization Guide

BlogIn modern manufacturing, the CNC Milling Machine is a core piece of equipment, widely applied in aerospace, mold manufacturing, automotive parts, and precision electronics. In scenarios involving complex processes such as laser beam welding, or requiring collaboration with CNC Machining Centers and CNC Vertical Machining Centers, its performance directly determines machining accuracy, surface quality, and… Continue reading CNC Milling Machine Performance Optimization Guide