Advantages of Vertical Milling Machines

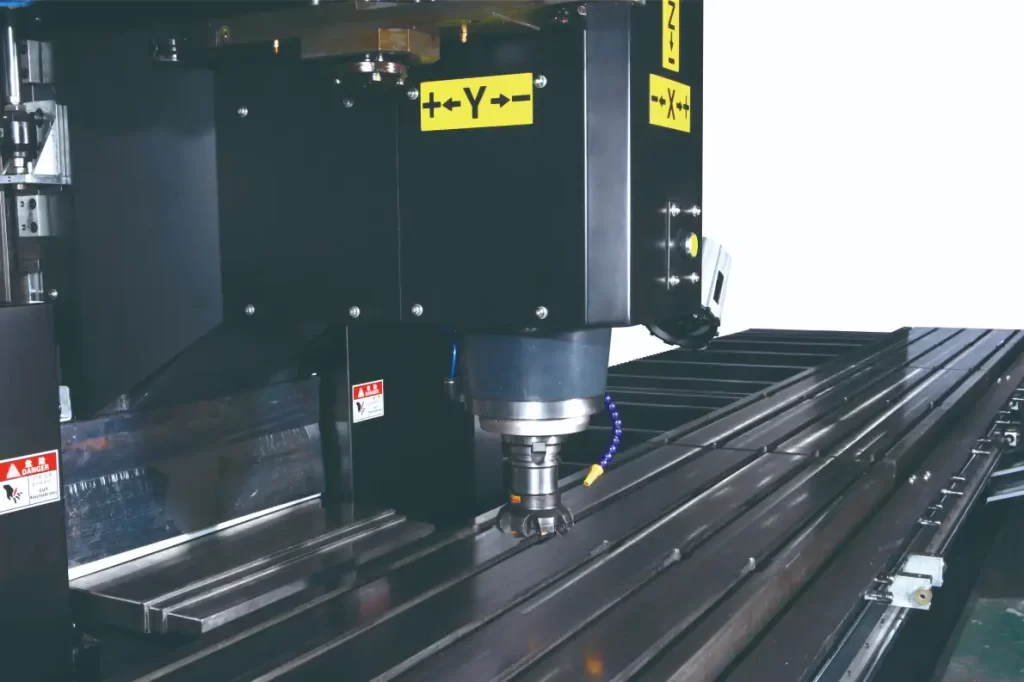

A vertical milling machine is a type of machine tool where the spindle is oriented perpendicular to the worktable. It cuts workpieces using a rotating tool and is widely used across various machining applications. Its core strengths lie in its flexibility and precision, making it a common sight from aerospace facilities to small workshops. For engineers and manufacturers, a vertical milling machine is not just a production powerhouse but also a significant driver of efficiency and cost reduction. This article will delve into the unique advantages of vertical milling machines, illustrating their value in modern manufacturing through practical application scenarios.

Key Advantages of Vertical Milling Machines

Operational Flexibility

The setup process for a vertical milling machine is surprisingly straightforward. Swapping a workpiece or changing a tool takes just minutes, allowing for exceptional adaptability. It can effortlessly handle both small components and complex geometries. Especially for small to medium-sized workpieces, whether round, square, or irregularly shaped, a vertical milling machine can complete the machining task with simple fixture adjustments. Compared to other equipment that requires cumbersome setups, its flexibility accelerates production cycles, making it particularly well-suited for scenarios requiring rapid task switching.

High-Precision Machining

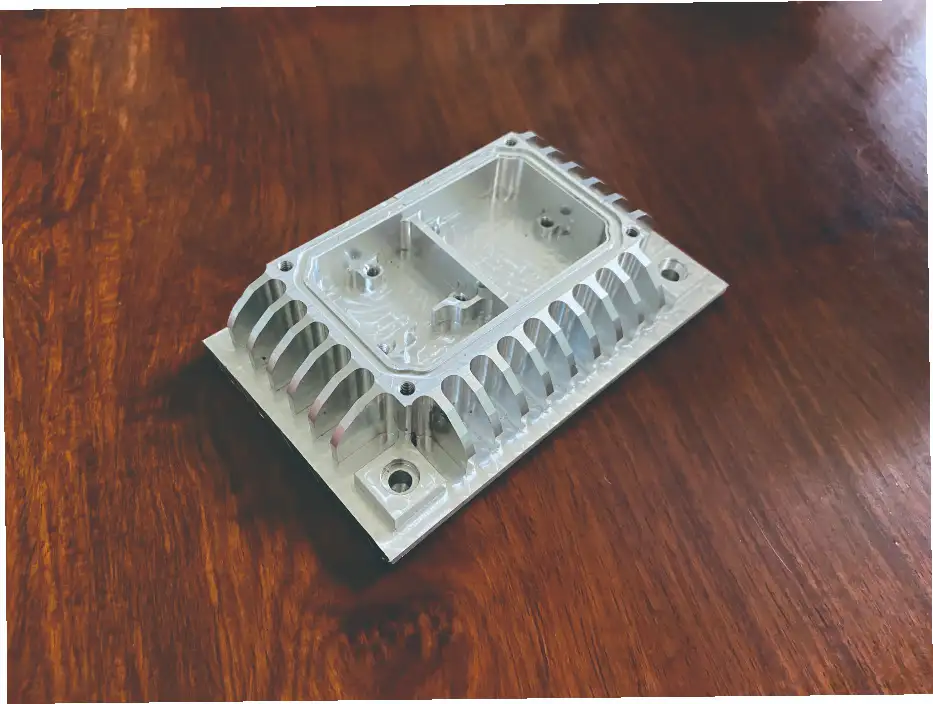

Precision is a vertical milling machine’s ace in the hole. It can achieve tolerances (machining error range) within ±0.01mm, meeting the stringent demands of high-precision fields like aerospace and medical devices. When machining complex curved or geometric shapes, the tool path is highly accurate, resulting in finished parts that rarely require additional finishing. The high surface finish reduces the need for secondary processing. For instance, when machining complex molds, a vertical milling machine can directly produce smooth surfaces, saving time and ensuring part quality.

Compact Design

Small workshops or startups with limited space often favor vertical milling machines. Their small footprint allows them to fit easily into cramped workshops. Compared to horizontal milling machines, which often require several square meters of floor space, vertical milling machines are truly “space magicians.” This compact design offers greater flexibility in production line layout, making them ideal for small to medium-sized businesses or temporary machining setups. Even with limited factory space, they can operate efficiently without concerns about equipment placement.

Cost-Effectiveness

The cost-effectiveness of vertical milling machines is remarkable. Their acquisition cost is lower than that of horizontal milling machines, and maintenance expenses are also modest, making them suitable for businesses with budget constraints. They excel in small-batch production or rapid prototyping; for example, when creating prototypes for new products, a vertical milling machine can quickly complete the task, saving significant trial-and-error costs. Tool changes are also simple, and operators can get started with minimal training, naturally reducing operating expenses. Compared to large-scale equipment requiring specialized maintenance teams, vertical milling machines are truly hassle-free and economical.

Multi-functional Processing

A single vertical milling machine can handle a wide range of tasks. It’s proficient in milling, drilling, and boring (enlarging holes), making it a true “multitool” in the machining world. It can process various materials, including metals, plastics, and composite materials, offering extensive adaptability. Whether it’s steel, aluminum alloys, or engineering plastics, a vertical milling machine can handle them with ease. What’s more impressive is its compatibility with both manual operation and Computer Numerical Control (CNC) systems, allowing small workshops to use manual modes and factories to utilize CNC modes, meeting diverse application needs.

Automation Compatibility

Vertical milling machines are a perfect match for automated production. They seamlessly integrate with mainstream CNC systems like Fanuc or Siemens, easily fitting into smart production lines. Automated production not only boosts efficiency but also ensures consistent quality for every part. For example, in mass production, CNC systems precisely control tool paths, reducing human error and significantly increasing the yield of qualified products. Businesses can also monitor equipment status through IoT technology, optimizing production plans and doubling efficiency.

Comparison Between Vertical and Horizontal Milling Machines

The primary differences between vertical and horizontal milling machines lie in the spindle orientation and workpiece clamping methods. A vertical milling machine’s spindle is perpendicular to the worktable, allowing for simple and flexible workpiece clamping, making it ideal for small to medium-sized workpieces. A horizontal milling machine’s spindle is horizontal, making it suitable for machining large, heavy workpieces, but it falls short in terms of flexibility and space requirements. Here’s a core comparison between the two:

| Parameter | Vertical Milling Machine | Horizontal Milling Machine |

|---|---|---|

| Spindle Orientation | Vertical, suitable for small to medium-sized workpieces | Horizontal, suitable for large workpieces |

| Footprint | Small, suitable for compact spaces | Large, requires spacious workshops |

| Machining Flexibility | High, quick adjustments | Moderate, suitable for fixed processes |

| Equipment Cost | Lower, low maintenance costs | Higher, complex maintenance |

| Machining Speed | Fast for small to medium-sized workpieces | Moderate for large workpieces |

| Suitable Scenarios | Small-batch, prototyping, diversified machining | Large-batch, heavy-duty machining |

Vertical milling machines offer clear advantages in machining small to medium-sized workpieces. They provide faster machining speeds, shorter workpiece and tool adjustment times, and lower cost and space requirements. While horizontal milling machines are more stable for heavy-duty machining, for scenarios requiring frequent task switching, vertical milling machines are clearly superior.

Application Areas of Vertical Milling Machines

- Aerospace: Vertical milling machines excel in the aerospace sector, becoming the preferred equipment for machining complex components like turbine blades and aerospace structural parts due to their high precision and reliability. Their precise tool control enables complex surface machining, meeting extremely strict tolerance requirements and ensuring component performance and safety.

- Automotive Manufacturing: In the automotive industry, vertical milling machines are widely used for producing high-precision molds and core engine components such as cylinder blocks, crankshafts, and gearbox housings. Their efficient and stable machining performance significantly boosts production efficiency and guarantees product quality.

- General Machinery: Vertical milling machines are versatile in the general machinery field, suitable for various part processing and equipment maintenance tasks. They can flexibly handle different materials and complex shapes, quickly complete high-precision machining, and adapt to diverse production needs.

- Education and Training: In vocational education and technical training, vertical milling machines are ideal teaching tools. Their simple and intuitive operation and high safety allow students to quickly get hands-on experience, mastering fundamental machining skills and laying a solid foundation for future career development.

Limitations and Countermeasures

Vertical milling machines are not without their limitations. When machining extremely large workpieces, their rigidity (the equipment’s ability to resist deformation) may be slightly insufficient, making them less stable than horizontal milling machines. Challenges may arise in scenarios requiring high rigidity, such as heavy cutting. To address these issues, the following measures can be taken:

- Use high-rigidity fixtures and cutting tools, such as carbide tools, to enhance machining stability.

- Introduce five-axis CNC technology (multi-axis simultaneous machining) to expand the machining range and easily handle complex workpieces.

- Upgrade the spindle and control system, for example, by adopting high-speed spindles and advanced CNC software, to improve equipment performance.