5 Common Types of CNC Machines

Hey manufacturing enthusiasts! Let’s dive into the world of CNC machines, the rockstars of modern production. Powered by CNC machining technology, these machines craft everything from smartphone components to jet engine parts with jaw-dropping, micron-level precision. In this guide, we’ll explore five common types of CNC machines, highlighting their roles in high-precision CNC processing equipment and their game-changing applications in automotive manufacturing CNC machines and aerospace precision machining. Whether you’re a shop owner or a tech geek, this rundown will spark your curiosity about the magic of CNC machines!

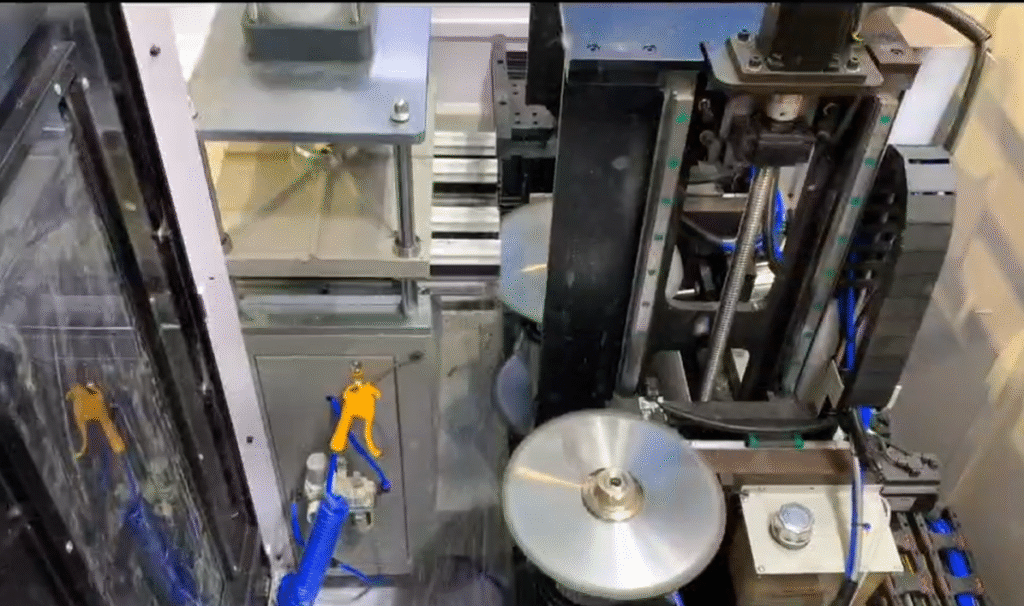

1. CNC Milling Machines

The Swiss Army knife of CNC machines, milling machines use rotating tools to carve slots, holes, flat surfaces, and even intricate 3D shapes. With multi-axis motion (X, Y, Z, and beyond), they deliver watchmaker-like precision, making them a staple in CNC machining centers.

Key Components:

- Spindle System: Powers the cutting tool, spinning at tens of thousands of RPMs, with auto-adjusting speeds for materials like aluminum or steel, and cooling systems to prevent heat distortion.

- Worktable: Secures the workpiece, moving along X/Y/Z axes with rock-solid rigidity for pinpoint mold-making accuracy.

- Tool Changer: Automatically swaps tools, slashing downtime and boosting efficiency.

Applications:

- Aerospace Precision Machining: Crafts turbine blades and aircraft frames to meet ultra-tight tolerances.

- Automotive Manufacturing CNC Machines: Churns out engine parts and molds in bulk, with tool changers speeding things up.

- General Machining: Perfect for prototyping and custom parts like complex valves.

Pros & Cons:

- Pros: Tackles complex geometries, handles diverse materials, and integrates seamlessly with CNC machining automation.

- Cons: High-end multi-axis models are pricey, programming requires expertise, and oversized or ultra-hard materials may need specialized gear.

2. CNC Lathes

Built for rotationally symmetric parts like shafts, rods, and cylinders, CNC lathes excel at high-precision turning, drilling, and threading. They’re a go-to for new energy vehicle parts processing.

Key Components:

- Chuck: Grips the workpiece tightly, available in 3-jaw, 4-jaw, or custom configurations.

- Tool Turret: Auto-swaps turning tools, drills, or even milling attachments for added versatility.

- Tailstock: Supports long workpieces to prevent bending during machining.

Applications:

- Rotational Parts: Produces automotive driveshafts or aerospace components with silky-smooth finishes.

- Threading: Creates precise internal and external threads to strict mechanical standards.

- Basic Machining: Handles outer turning, face machining, and boring for simple or complex tasks.

Pros & Cons:

- Pros: High precision, ideal for high-volume production, minimizes human error.

- Cons: High upfront costs, requires skilled programmers, and non-symmetric parts need other CNC machines.

3. CNC Plasma Cutting Machines

The heavy-hitters of metal cutting, plasma cutters use super-hot plasma arcs to melt materials, with compressed gas blowing away debris. They’re perfect for slicing steel, aluminum, and other conductive metals, especially in rail transit parts processing equipment.

Key Components:

- Plasma Torch: Generates the plasma arc, with nozzle design critical for cut quality.

- CNC Controller: Reads G-code to guide the torch with precision.

- Worktable: Equipped with water trays or exhaust systems to manage heat and fumes.

Applications:

- Metal Fabrication: Cuts steel beams or artistic sculptures, handling thicknesses from 1-50mm.

- Automotive Repair/Modification: Quickly slices body panels or custom parts.

- Industrial Construction: Mass-produces steel frames or piping with high-quality cuts.

Pros & Cons:

- Pros: Cost-effective, quick setup, great for medium-to-thick metals.

- Cons: Less precise than lasers, struggles with ultra-thin or ultra-thick materials, and requires ventilation for fumes.

4. CNC Laser Cutting Machines

Laser cutters use focused, high-energy beams to slice through materials, with assist gases clearing molten debris. They produce clean edges on metals, wood, or acrylic, making them a top pick for 5G equipment manufacturing machines.

Key Components:

- Laser Head: Focuses the beam for micron-level precision.

- Optical System: Lenses or fiber optics guide the laser, ensuring stable energy delivery.

- Cooling System: Water-cooling keeps things stable during long runs.

Applications:

- Micro-Machining: Cuts microelectronics or medical components with micron-level accuracy.

- Engraving: Etches intricate patterns on wood or metal for custom designs.

- Sheet Metal Processing: Slices stainless steel panels for automotive manufacturing CNC machines.

Pros & Cons:

- Pros: Unmatched precision, minimal material waste, excels at complex patterns.

- Cons: High cost and maintenance, less efficient for thick metals compared to plasma cutters.

5. CNC Electrical Discharge Machines (EDM)

EDM machines use electrical sparks to erode conductive materials, perfect for ultra-hard metals or intricate shapes that standard CNC machines can’t handle. They’re a hallmark of precision mechanical processing equipment.

Key Components:

- Electrode: Made of copper or graphite, shaped to match the target part, controlling spark erosion.

- Dielectric System: Uses deionized water or oil for cooling and debris removal.

- Pulse Power Supply: Generates high-frequency pulses to fine-tune precision and surface finish.

Applications:

- Mold Making: Produces injection or stamping molds with mirror-like finishes.

- Tool Manufacturing: Crafts hard-alloy tools or medical devices.

- Complex Cavities: Cuts deep holes or narrow slots that milling can’t touch.

Pros & Cons:

- Pros: Non-contact machining, handles any conductive material hardness, delivers exceptional surface finishes.

- Cons: Slow process, electrodes wear out, limited to conductive materials.

CNC Machine Comparison Chart

| Machine Type | Precision | Best Use | Cost Range (USD) |

|---|---|---|---|

| Milling | High | Complex Shapes | $40,000-$400,000 |

| Lathe | High | Cylindrical Parts | $30,000-$300,000 |

| Plasma | Moderate | Metal Cutting | $15,000-$85,000 |

| Laser | Ultra-High | Thin Materials | $40,000-$350,000 |

| EDM | Ultra-High | Hard Materials | $70,000-$550,000 |

*Note: Compares CNC machine precision, applications, and CNC machining center prices.

Wrap-Up: Which CNC Machine Fits Your Shop?

Partnering with a trusted CNC machine manufacturer is the key to success. Each CNC machine shines in its own way:

- Milling Machines: The go-to for complex 3D shapes.

- Lathes: Masters of rotationally symmetric parts.

- Plasma Cutters: Budget-friendly metal cutting champs.

- Laser Cutters: Precision kings for fine work.

- EDM: The solution for ultra-hard materials and tricky geometries.

By understanding the strengths and weaknesses of each CNC machine and exploring tailored CNC machining solutions, you’ll find the perfect fit for your needs. Want to dive deeper? Reach out to DELI for a custom quote, or drop a comment below to share your project needs and thoughts on CNC machine brands. Let’s connect with fellow manufacturing enthusiasts!