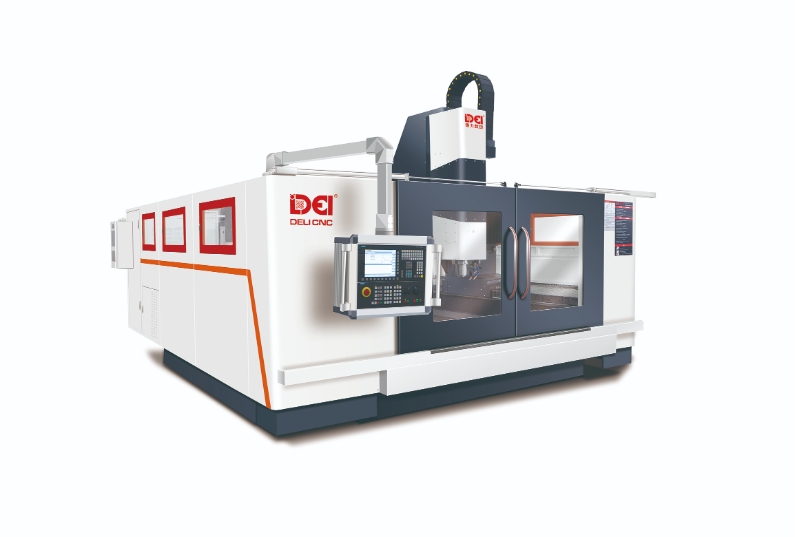

5 Axis CNC Gantry Machiining Ceter MDF

The MD Series 5-axis CNC vertical machining center delivers precision and efficiency for industries like mold manufacturing, automotive, aerospace, electronics, and furniture. It excels in milling, drilling, tapping, and boring complex parts, including MDF for furniture and decorative applications.

Main features:

- Sturdy Build: High-strength cast iron with optimized design ensures stability, reduces thermal distortion, and boosts machining accuracy.

- High-Speed Spindle: Precision spindle enables rapid cutting and detailed processing. Select direct-connected or belt-type spindles for optimal performance.

- Fast Tool Changer: Servo-driven ATC provides quick, reliable tool changes, minimizing downtime and increasing productivity.

- Smart CNC Controls: Fanuc, Siemens, or Mitsubishi systems support multi-axis coordination and flexible programming for high precision.

- MDF Processing: Efficiently handles MDF, wood, composites, and metals, perfect for furniture, mold making, and 3D designs.

| TRAVEL | |

| Model | MD 2518 |

| X-Axis stroke | 2500mm |

| Y-Axis stroke | 1800mm |

| Z-Axis stroke | 700mm |

| Distance from spindle nose to table surface | 120-820mm |

| SPINDLE | |

| Spindle speed | 12000(r.p.m) |

| Taper | BBT40 |

| Type | Mechanical |

| TOOLS | |

| Tool changer format | Disc type |

| Pull studs format | BT40 |

| Tool capacity | 24 |

| Tool change time | 1.8ses |

| MOVING SPEED | |

| X-Axis moving speed | 60m/min |

| Y/Z-Axis moving speed | 60/25m/min |

| Feeding Speed | 1~20000mm/min |

| Worktable Size (Length*Width) | |

| MD 2518 | 2500 X 1800 mm |

| POWER OF MOTOR | |

| Spindle driven motor | 11/18.5KW |

| X/Y/Z driven motor | 3.0/3.0/3.0kw |

| SIZE OF MACHINE | |

| Operation system | FANUC/SIEMENS |

| Height | 3600mm |

| Other lengths can be custominzed | |

| See technical agreement for details | |